Repairing method for cooling staveleakage

A repair method and technology of cooling wall, applied in cooling devices, coatings, arc welding equipment, etc., can solve the problems of reduced thermal conductivity and cooling capacity, inability to repair large cracks, etc., and achieve the effect of restoring the cooling function and reducing the repair cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

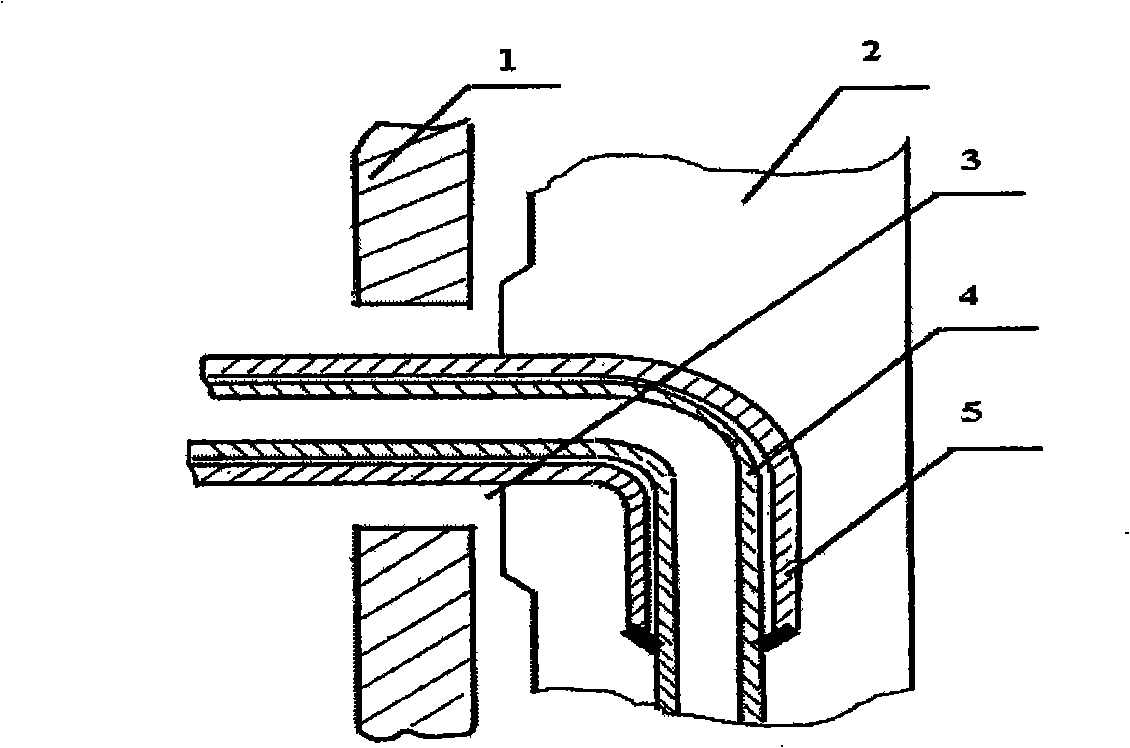

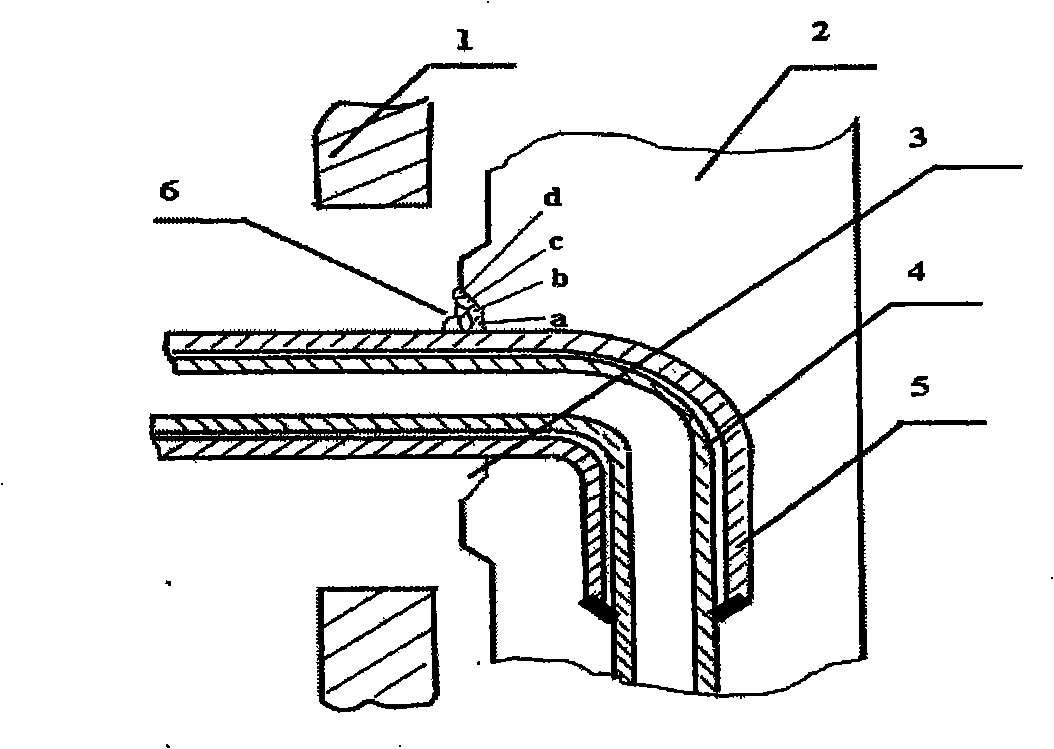

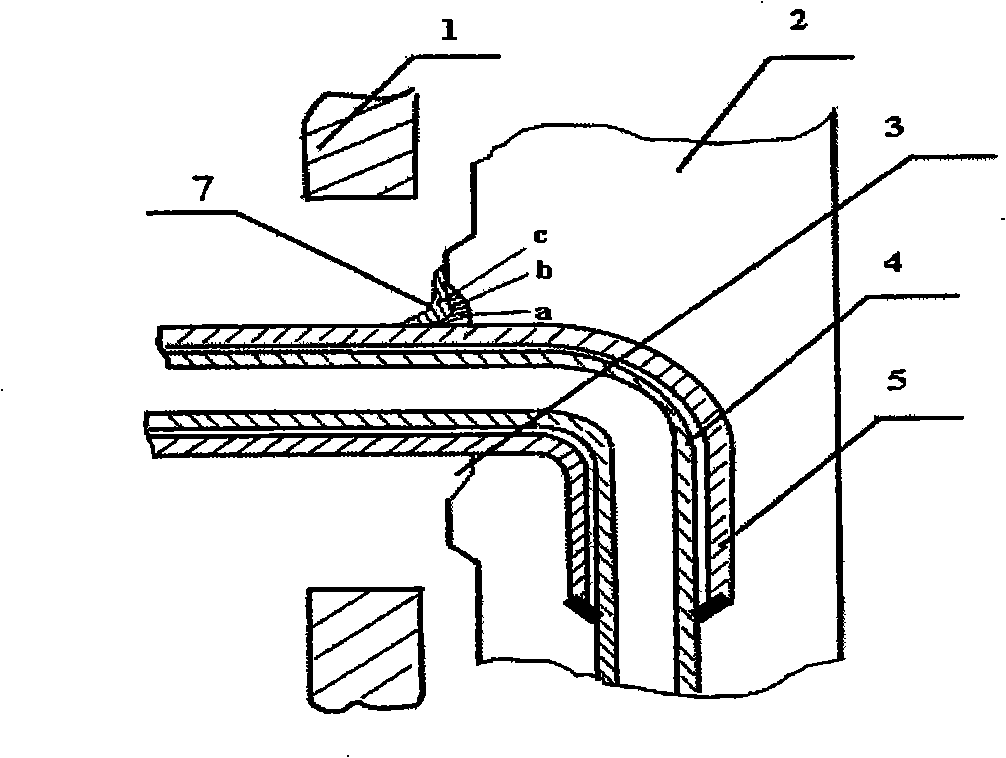

[0019] Example 1: The material of the stave of the blast furnace is HT150, the specification of the cooling water pipe is Ф44.5×6mm, the specification of the sleeve is Ф63.5×5mm, the leaking part is at the root of the casing and the stave boss, and the cooling water is sprayed. The leak is serious. To this end, adopt the inventive method to carry out leakage repair now, refer to figure 1 , 2 , 3, explain the repair process as follows:

[0020] 1. Using the oxyacetylene flame cutting method, with the stave water pipe as the center, open a hole in the furnace shell 1 with a diameter of Ф180mm.

[0021] 2. Make grooves around the root 3 of the leaking stave water pipe and casing boss to remove cracks and defects such as molding sand, slag inclusions, and looseness on the stave surface. The groove depth is 4-6 mm, and the width on one side is about 15 mm, forming the groove structure of the stave boss at the root of the water pipe 4 and the sleeve pipe 5 .

[0022] 3. Turn off...

Embodiment 2

[0025] Example 2: The material of the stave of the blast furnace is HT150, the specification of the cooling water pipe is Ф44.5×6mm, the specification of the sleeve is Ф63.5×5mm, the leaking part is at the root of the casing and the boss of the stave, and the surface of the cast iron at the boss has There are many loose cavities, and the fusion quality between the weld metal and the cast iron surface during welding is very poor. Many times of welding repairs have not been fundamentally resolved, and the leakage is serious. In this regard, the method of the present invention is now used to repair the leakage, with reference to the attached figure 1 , 2 , 3, explain the repair process as follows:

[0026] 1. Using the oxyacetylene flame cutting method, with the stave water pipe as the center, open a hole in the furnace shell 1 with a diameter of Ф180mm.

[0027] 2. Grooving at the root: groove around the root of the stave of the leaking water pipe (casing) to remove cracks and...

Embodiment 3

[0031] Embodiment 3, first adopt the method of embodiment 1, build up welding on the bottom layer, then use the method of embodiment 2 to coat the polymer metal layer on the build up layer, stick a layer of reinforced carbon fiber again, and finally coat a layer polymer polymer metal. The feasibility and prospect of the expected popularization and application of the invention:

[0032] Leakage of staves is common in the production of blast furnaces in iron and steel enterprises, and it is a practical production problem that is difficult to solve. Leakage of staves will cause erosion of the blast furnace lining and reduce its service life. Iron production capacity. The invention only needs to use the opportunity of the blast furnace shutdown for maintenance to repair the leakage of the stave, and the operation is simple and convenient, and the repair time only needs 6-7 hours. Therefore, it has wide promotion and application value in the iron and steel industry, and the marke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com