Cleaner multilevel noise reduction device

A technology of vacuum cleaner and noise, which is applied in the field of vacuum cleaner manufacturing to achieve the effect of small size, excellent noise reduction effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

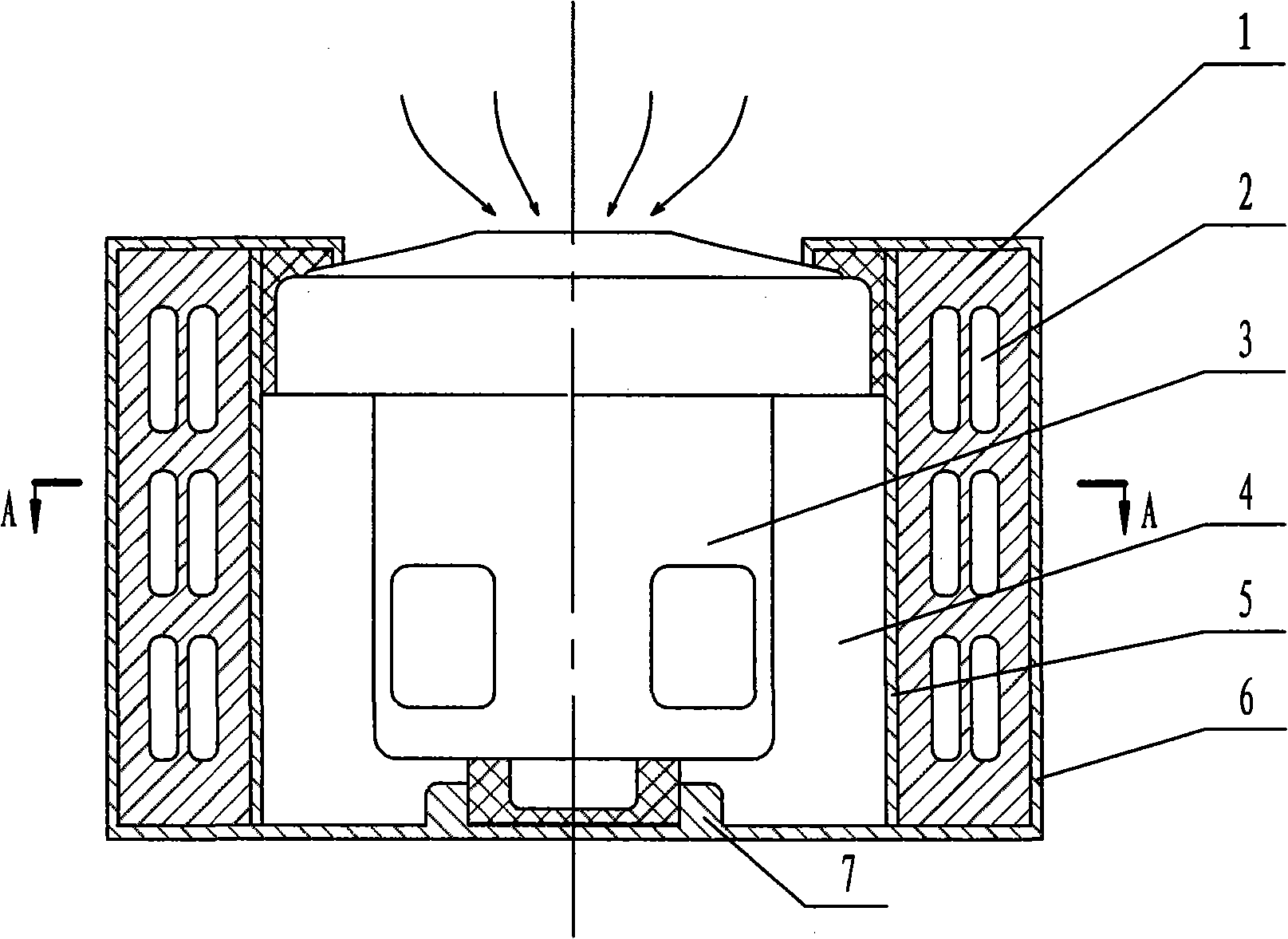

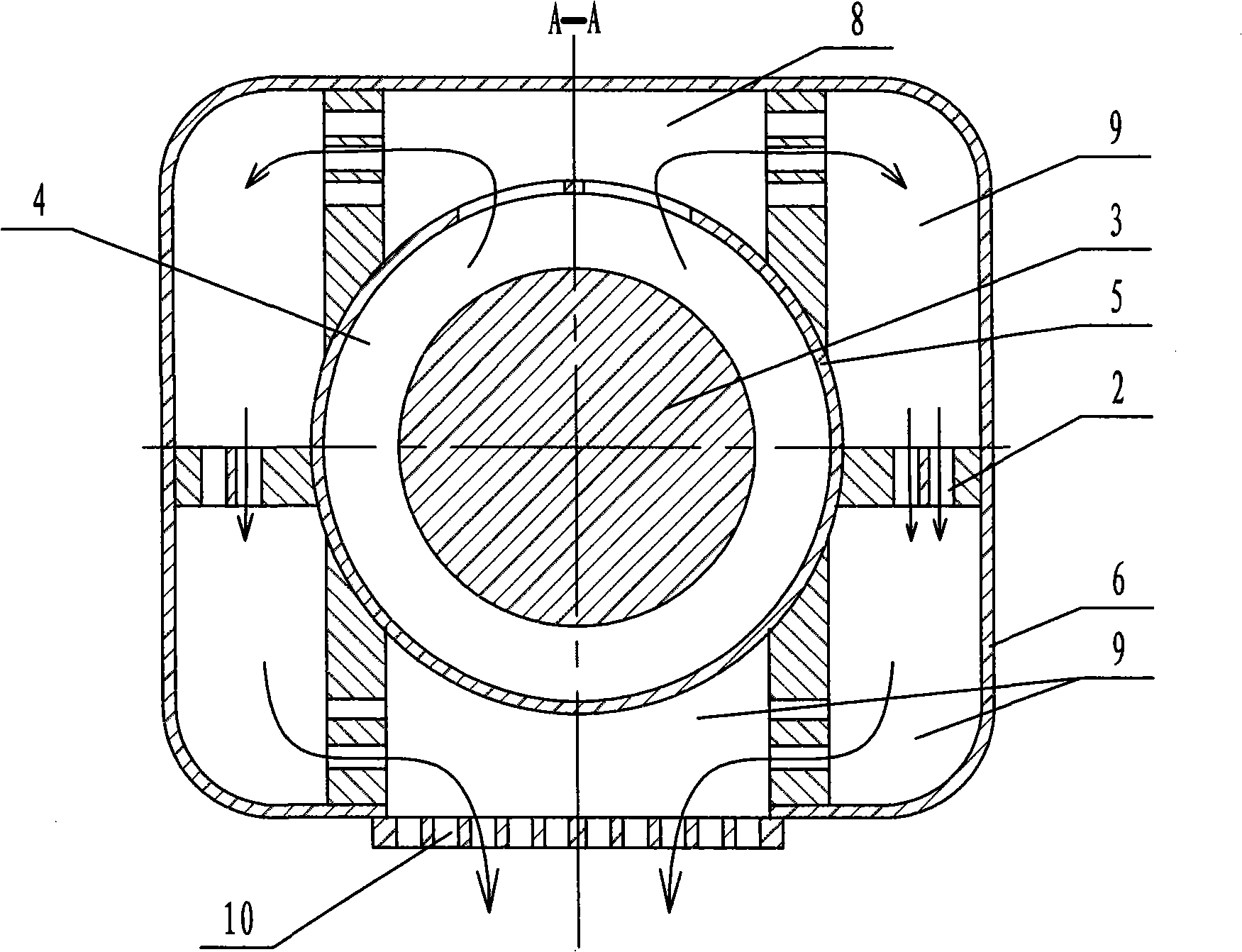

[0018] figure 1 , figure 2 , image 3 , Figure 4 It is an embodiment of the present invention.

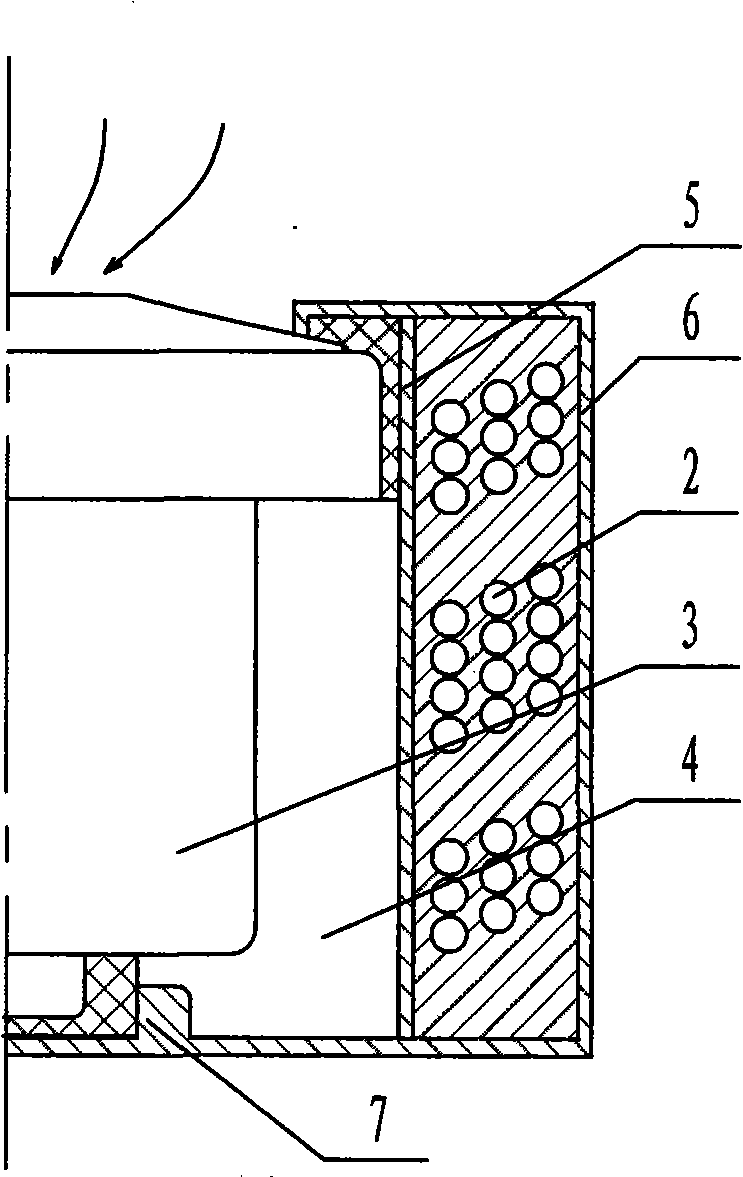

[0019] The vacuum cleaner multi-stage noise reduction device includes an electric fan 3 and a vacuum cleaner base 7 supporting it. The motor inner cover 5 and the outer cover 6 that are spaced from each other are installed on the periphery of the electric fan, so that the inner air duct 4 and the outer air duct for air circulation are formed between the electric fan 3 and the inner motor cover 5, and the inner motor cover and the outer cover. The electric fan inner cover 5 in the figure is circular, and the outer cover 6 is rectangular or circular. One or several shrink tube brackets 1 are inserted axially in the outer air duct between the inner cover 5 and the outer cover 6 of the electric fan, which isolates the outer air duct into a resonant chamber 8 connected to the air inlet and a plurality of different lengths. The airtight expansion chamber 9. On the shrink tube sup...

Embodiment 2

[0021] Figure 5 is another embodiment of the present invention. In this embodiment, the motor inner cover 5 and the outer cover 6 arranged on the periphery of the electric fan 3 are both circular, and the shrink tube brackets 1 of the shrink tube 2 with small holes or slender holes are connected to the inside of the motor in the radial direction. Between the cover 5 and the outer cover 6, the outer air duct is radially divided into several expansion chambers 9 of different sizes or evenly distributed, and the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

[0023] Image 6 It is another embodiment of the present invention. In this embodiment, the shrink tube support 1 can be sequentially connected between the motor inner cover 5 and the outer cover 6 along the axial direction of the electric fan. These small holes or slender thin holes are preferably mutually misplaced, and it divides the external air duct into a resonant chamber 8 connected to the air inlet and several expansion chambers 9 axially up and down behind the resonant chamber 8 . All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com