Full-automatic control system of oil field heating furnace

A control system and heating furnace technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of not being able to achieve automatic control, and achieve the effect of unattended automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

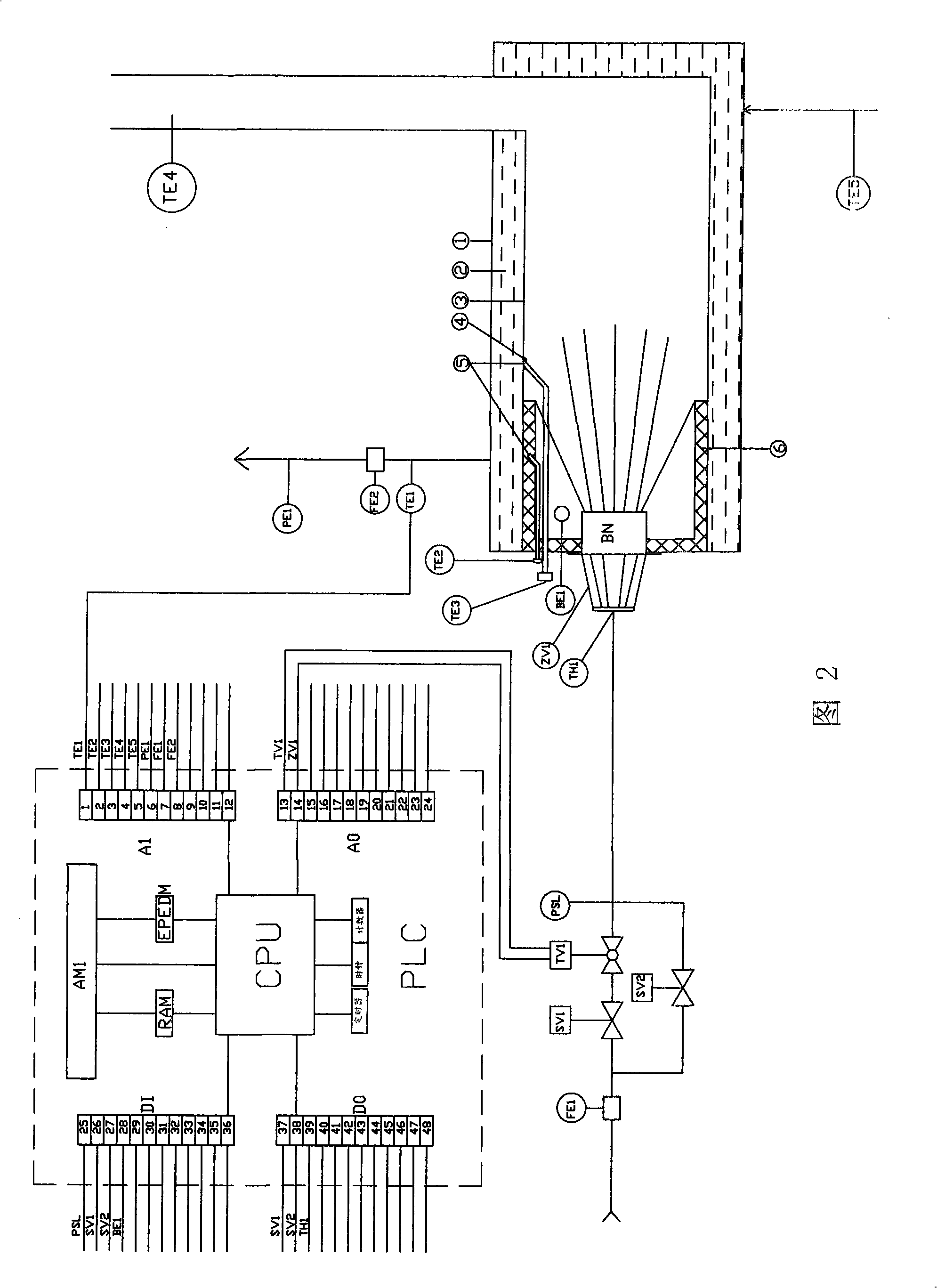

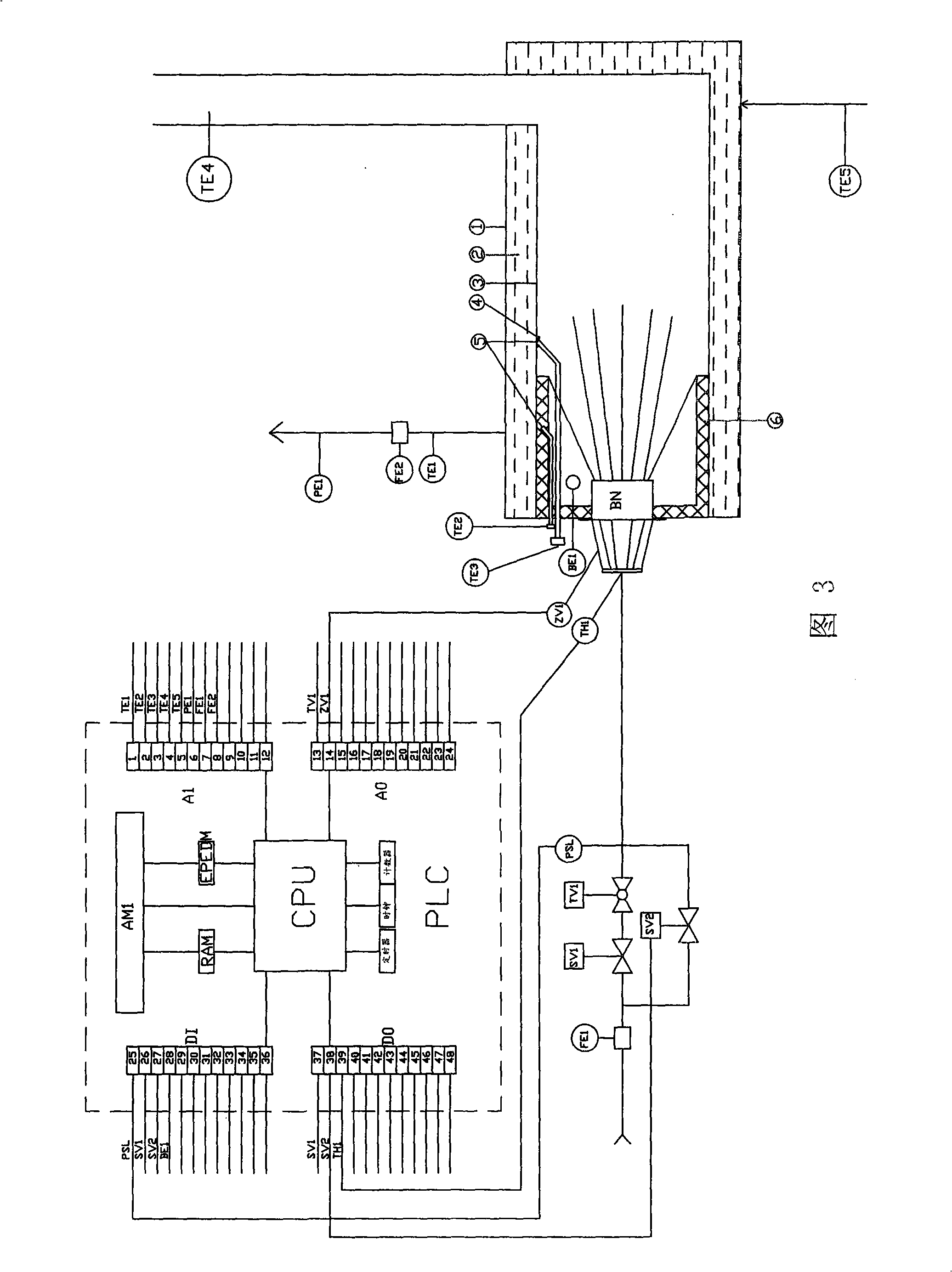

[0020] Below in conjunction with accompanying drawing 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, the present invention is further described:

[0021] In order to achieve the purpose of this utility model, in the present invention, certain improvements have been made in the existing oil field heating furnace. The detection instruments and equipment installed on the heating furnace include: the temperature transmitter at the outlet of the heating furnace TE1 outlet pressure transmitter PE1, outlet flow transmitter FE2, flue temperature transmitter TE4, inlet temperature transmitter TE5, furnace tube temperature transmitter TE2, TE3, flame detector BE1, burner BN igniter TH1, damper Actuator ZV1, ignition solenoid valve SV2, main solenoid valve SV1, gas flow transmitter FE1. The heating furnace includes: outer sealing cylinder 1, heated medium 2, such as oil or water, fire cylinder steel plate 3, solder joint 4, temperature detection element 5, and refractory brick 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com