Assembly-line automatic manufacturing technology for pre-stressed concrete track board unit by pre-tensioning method

A manufacturing technology and assembly line technology, applied in the direction of tracks, manufacturing tools, roads, etc., can solve the problems of high volatility, low degree of automation, and many loopholes

Active Publication Date: 2017-03-01

SHANDONG LINQU SLEEPER

View PDF5 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The manufacturing process of the fixed station mode is characterized by man-machine cooperation, low degree of automation, large number of workers, high labor intensity, production cycle of 20h-22h, low efficiency, large production site occupied by the tension pit, and the product After the production is completed, the tension pit cannot be relocated, resulting in waste; the product quality is limited by the process conditions, and the fluctuation is relatively large. The supervision depends on spot checks, and there are many loopholes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Deformed example 2

[0125] For different processes, the same assembly line production mode can be produced by increasing or reducing process steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

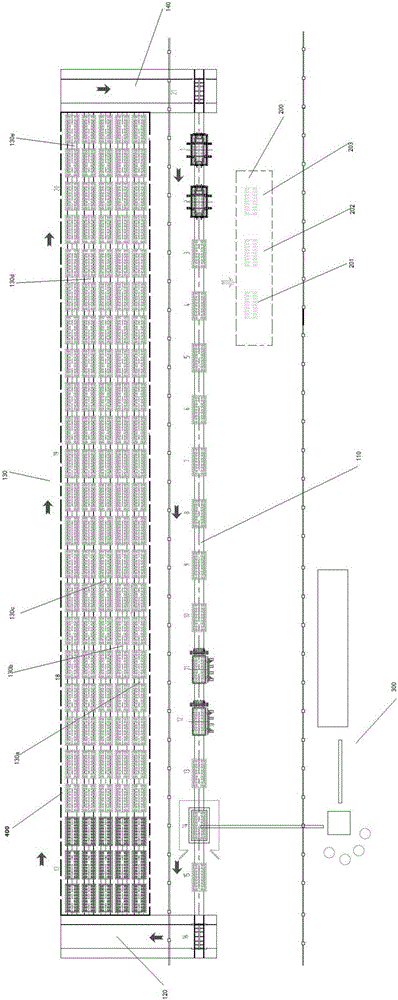

The invention provides an assembly-line automatic manufacturing technology for a pre-stressed concrete track board unit by a pre-tensioning method. Traction equipment drives a model to flow on a track according to a time beat, wherein the time beat is working time of each station; the model bears tensioning stress, and all the stations are lined up on an assembly line and work together at the same time; and the quality and the working progress of each station are controlled by a sensor, and each station is commanded by a central control system, so that the operation of the whole system is controlled. Compared with a matrix production method, the assembly-line automatic manufacturing technology has the advantages that temporary components such as a tensile pedestal are eliminated, the model turnover rate is increased by 50 percent, the area of a factory is reduced by 30 percent or above, and the number of workers is reduced by 50 percent or above. The production process fulfills the aims of full-automatic control, informationalized transmission of key data, remote monitoring, and relocation and quick installation of all sets of equipment according to engineering requirements.

Description

technical field [0001] The invention relates to a manufacturing method of a track plate product in a high-speed railway track structure. An automatic manufacturing technology for a pretensioned two-way prestressed reinforced concrete track slab assembly line assembly line, in particular relates to the conversion of traditional pretensioned manufacturing technology to automated and informationized manufacturing technology. Background technique [0002] At present, the known high-speed railway track slabs have two methods: pre-tensioned structure and post-tensioned structure. Therefore, there are two manufacturing methods. The common feature of these two manufacturing methods is the fixed platform method. [0003] The so-called fixed-position method mode refers to the mode in which the model does not move, and other operating procedures cooperate with the model to operate in turn. For example, the traditional pre-tensioning manufacturing process first designs and builds a loa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28B15/00B28B23/04B28B17/00B28B13/06B28B7/38B28B13/02B28B11/24B28B1/04E01B1/00

CPCB28B1/045B28B7/382B28B11/245B28B13/023B28B13/065B28B15/007B28B17/0081B28B23/043E01B1/002B28B15/00B28B23/04E01B1/00

Inventor 林晓波张长春黎开政刘忠义郑红兵许欣钱振地税卓平李晓荣黄兴启殷强裴磊

Owner SHANDONG LINQU SLEEPER

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com