Method for sieving pendulum shaft and pendulum shaft sieving machine thereof

A screening and sieve surface technology, which is applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problem of high cost of screen body, high cost of equipment and wearing parts, and deterioration of screening efficiency, etc. problems, to achieve the effect of low vibration and noise, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

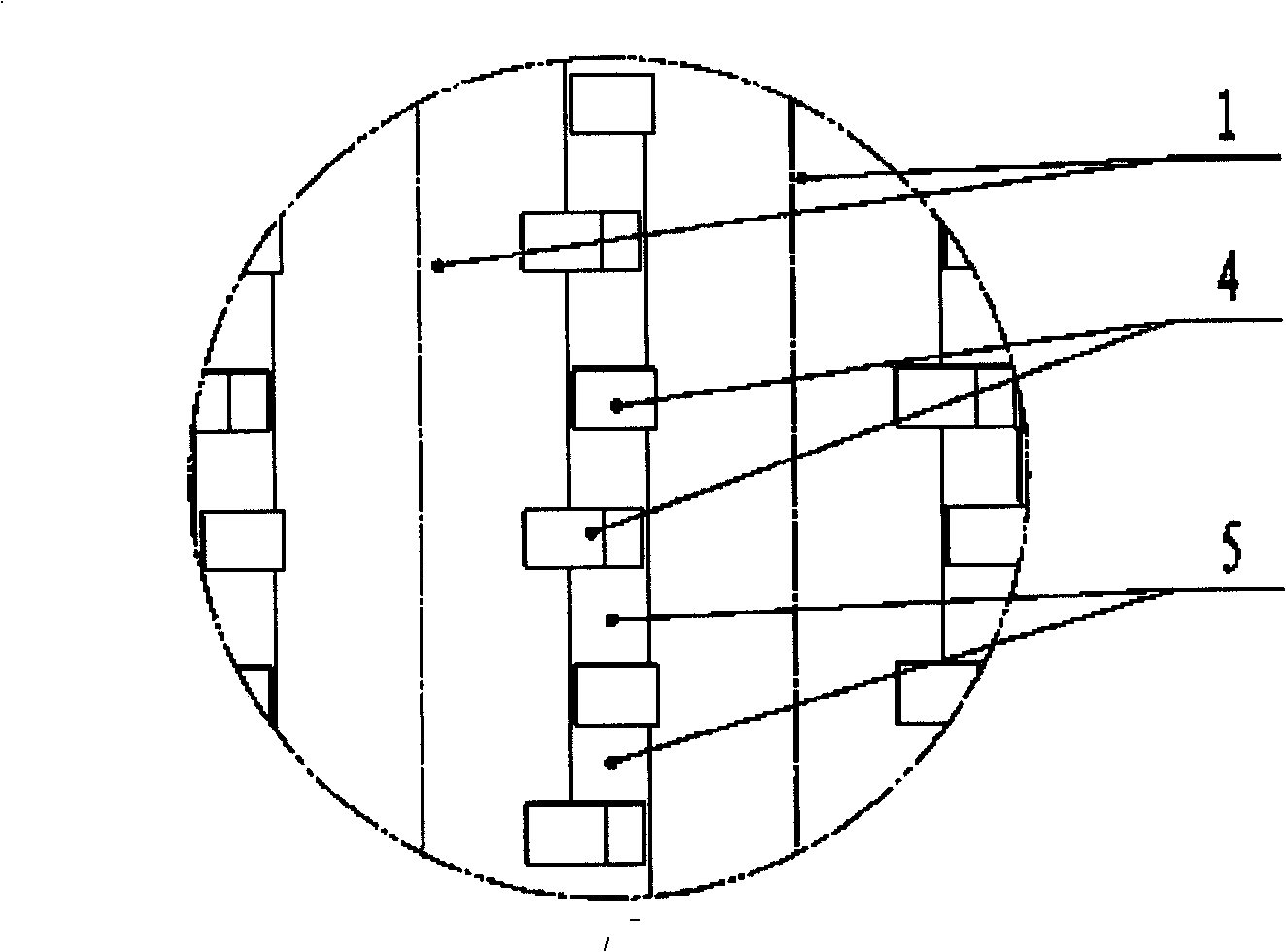

[0029] As shown in Fig. 1 and Fig. 2, the pendulum screening machine of the present invention includes a screen surface 2 and a screen hole 5, and a plurality of pendulum shafts 1 are installed side by side on the screen surface 2 frame, and two opposite pendulum shafts 1 on each pendulum shaft 1 The side is provided with a plurality of fins 4, and the fins 4 on adjacent shafts 1 are arranged in a staggered manner (such as image 3 ), the gap between the adjacent shaft 1 and the gap between the wings 4 on the adjacent shaft 1 constitutes a sieve hole 5 (such as Figure 4 ).

[0030] A pendulum screening method according to the present invention, the specific embodiment is to install a plurality of pendulum shafts 1 side by side on the frame of the screen surface 2, the gap between adjacent shafts 1 is the size of one direction of the sieve hole 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com