Sensor and test device for testing tone key of musical box

A technology of sensors and keys, which is applied in the field of tuning of octave soundboards and testing devices, can solve the problems of inability to use sensors, low production efficiency, large equipment volume, etc., achieve long service life, reduce workstations, and test high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

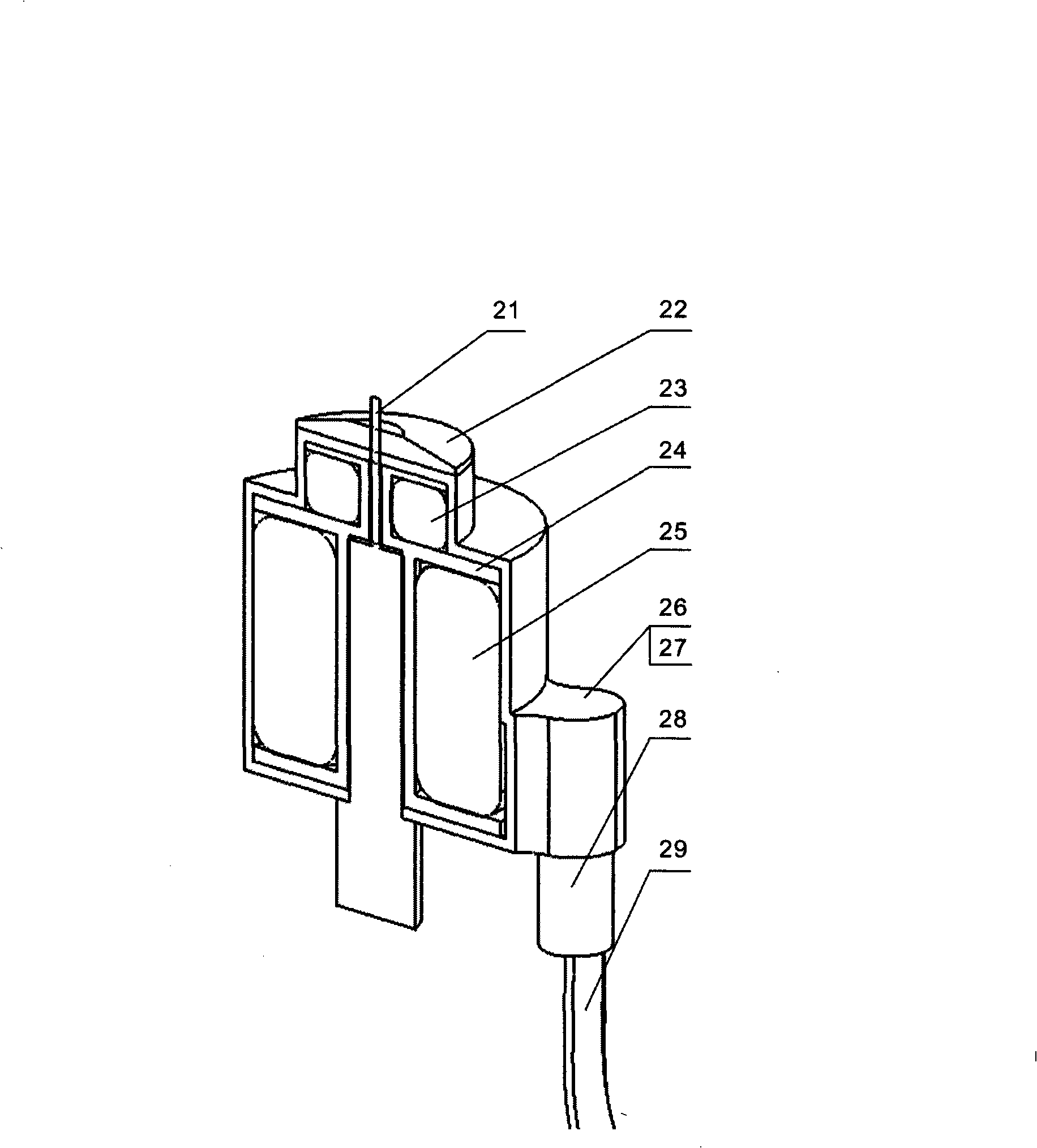

[0023] Such as figure 2 Shown, the sensor for musical instrument key test comprises shell 26, iron core 21, vibrating coil 23, bobbin 24, suction coil 25, signal amplifying circuit 27, sealing ring 28, lead 29, cover plate 22.

[0024] The bobbin 24 is arranged in the middle of the housing 26, and the core 21 is inserted in the center, and the vibration measuring coil 23 and the suction coil 25 are wound on it.

[0025] The above-mentioned components are integrally injection-molded with the housing 26 to improve the sealing performance of the entire sensor.

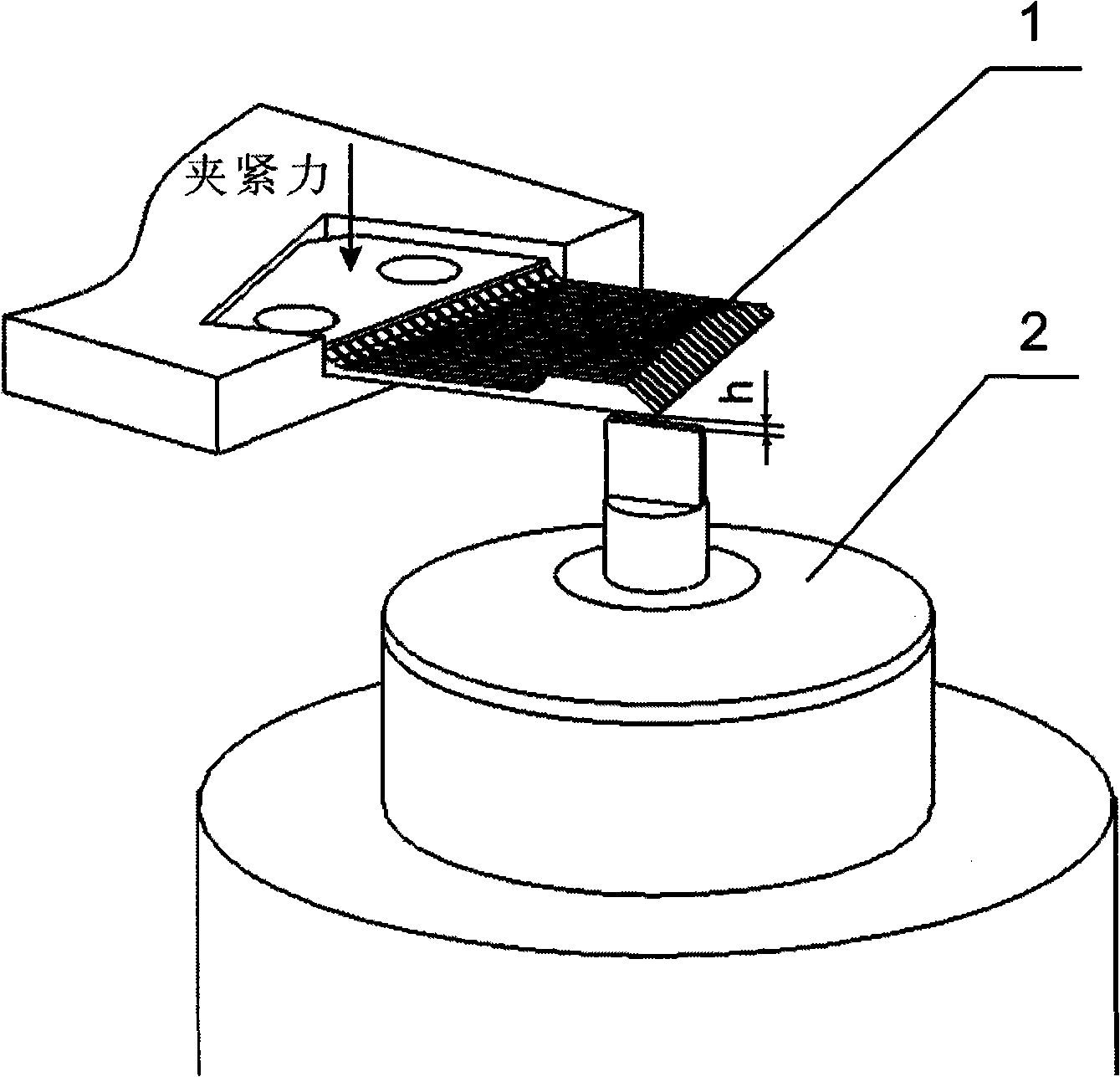

[0026] Such as figure 1 As shown, when the above-mentioned sensor is applied to the automatic frequency tuning equipment of the sound board, it is installed under the sound board, and the head of the flat iron core 21 is parallel to the direction of the key. The frequency of pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com