Inner pressure type temperature compensation high-temperature high-pressure optical fiber grating sensor

A technology of fiber grating and temperature compensation, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of low detection pressure of fiber grating pressure sensors, low sensitivity of temperature and pressure sensors, and small detection range, etc., to improve Effect of pressure and temperature measurement range, improvement of repeatability and stability, improvement of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

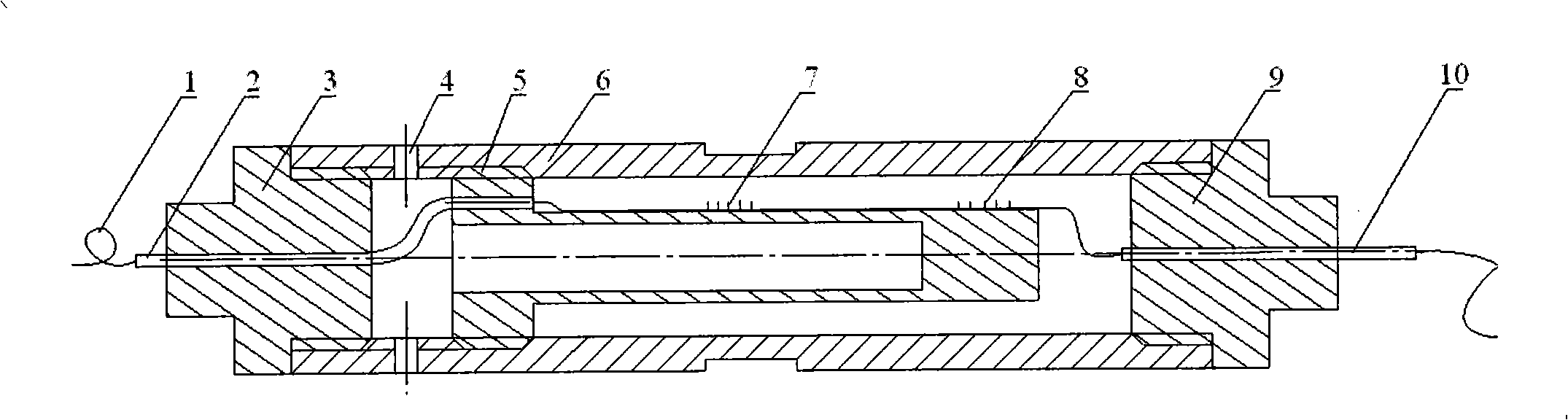

[0023] exist figure 1 Among them, the internal pressure temperature compensation high temperature and high pressure fiber grating sensor of this embodiment consists of an optical fiber 1, a left capillary steel pipe 2, a left coupling head 3, an oil inlet 4, an elastic base 5, a housing 6, and a pressure sensing fiber grating 7 , temperature sensing fiber grating 8, right connecting head 9, and right capillary steel pipe 10 are connected to form.

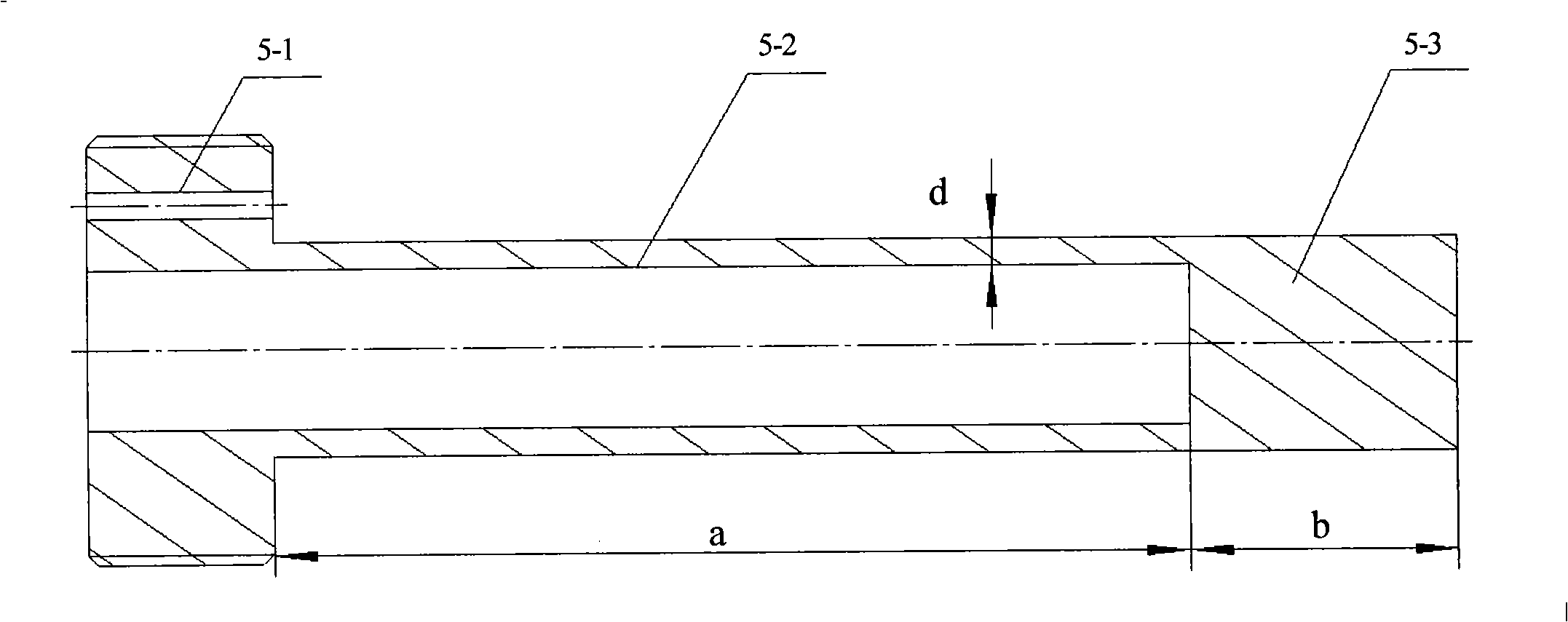

[0024] An oil inlet hole 4 is radially processed on the left side of the casing 6, and the oil and natural gas in the oil well can enter the casing 6 through the oil inlet hole. The thread connection is equipped with an elastic base 5, and the left end of the elastic base 5 is welded and sealed with the housing 6 after the elastic base 5 is threadedly connected with the housing 6, and the left end of the elastic base 5 should be positioned at the right side of the oil inlet hole. The left end edge of the elastic base 5 is processed...

Embodiment 2

[0027] In this embodiment, the wall thickness d of the pressure fiber grating substrate 5-2 is 0.8 mm, the length a is 30 mm, the length b of the temperature fiber grating substrate 5-3 is 15 mm, and the temperature sensor fiber grating 8 is manufactured at a wavelength of 1430 nm , the fabrication wavelength of the pressure sensing fiber grating 7 is 1435nm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0029] In this embodiment, the wall thickness d of the pressure fiber grating substrate 5-2 is 2mm, the length a is 60mm, and the length b of the temperature fiber grating substrate 5-3 is 20mm. The fabrication wavelength of the temperature sensing fiber Bragg grating 8 is 1650nm, and the fabrication wavelength of the pressure sensing fiber Bragg grating 7 is 1655nm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com