Hydraulic pipe drawing device

A hydraulic and hydraulic system technology, applied in the field of construction equipment, can solve problems such as the inability to achieve height and the impact of large-scale production, and achieve the effects of large pulling force, simple structure and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

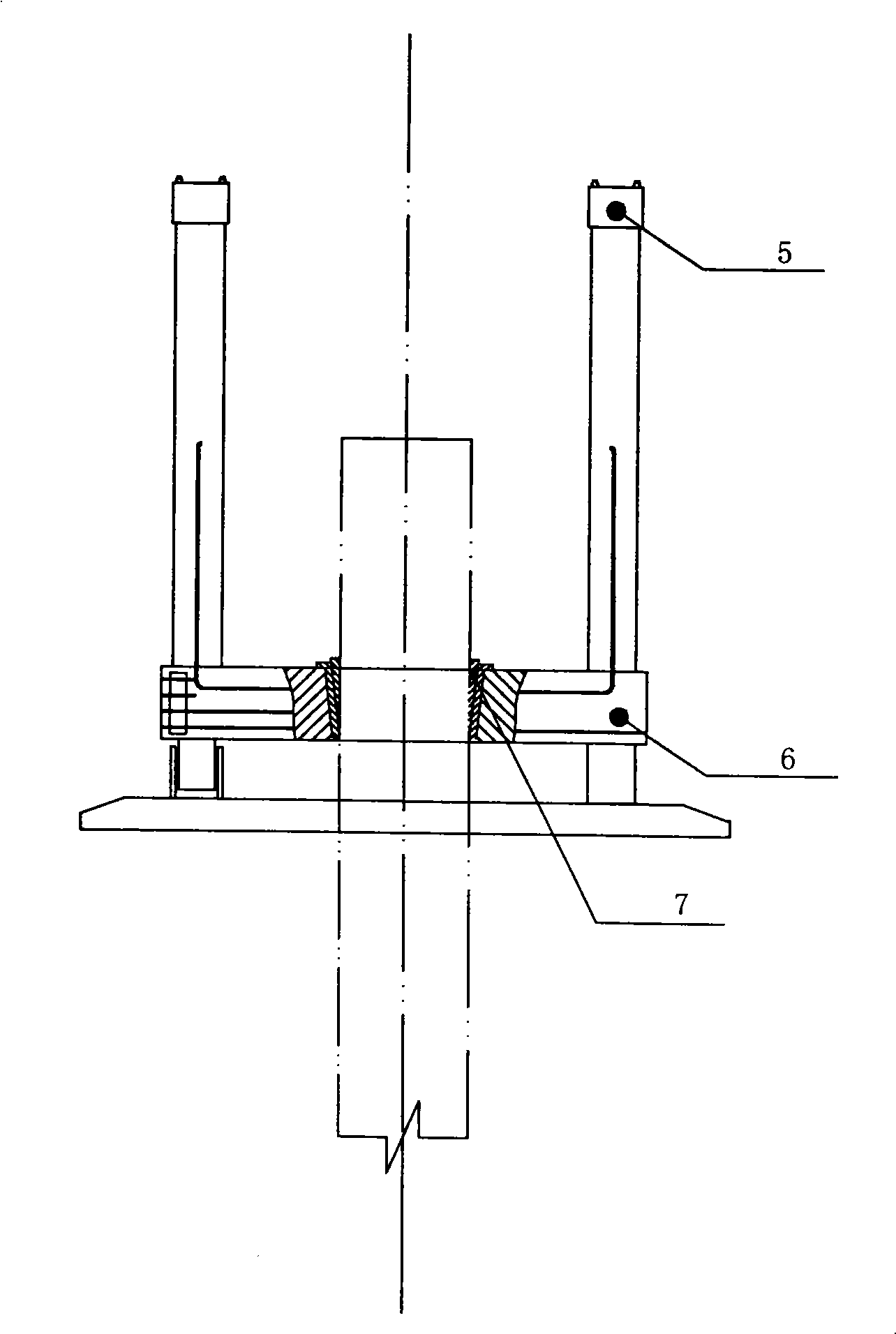

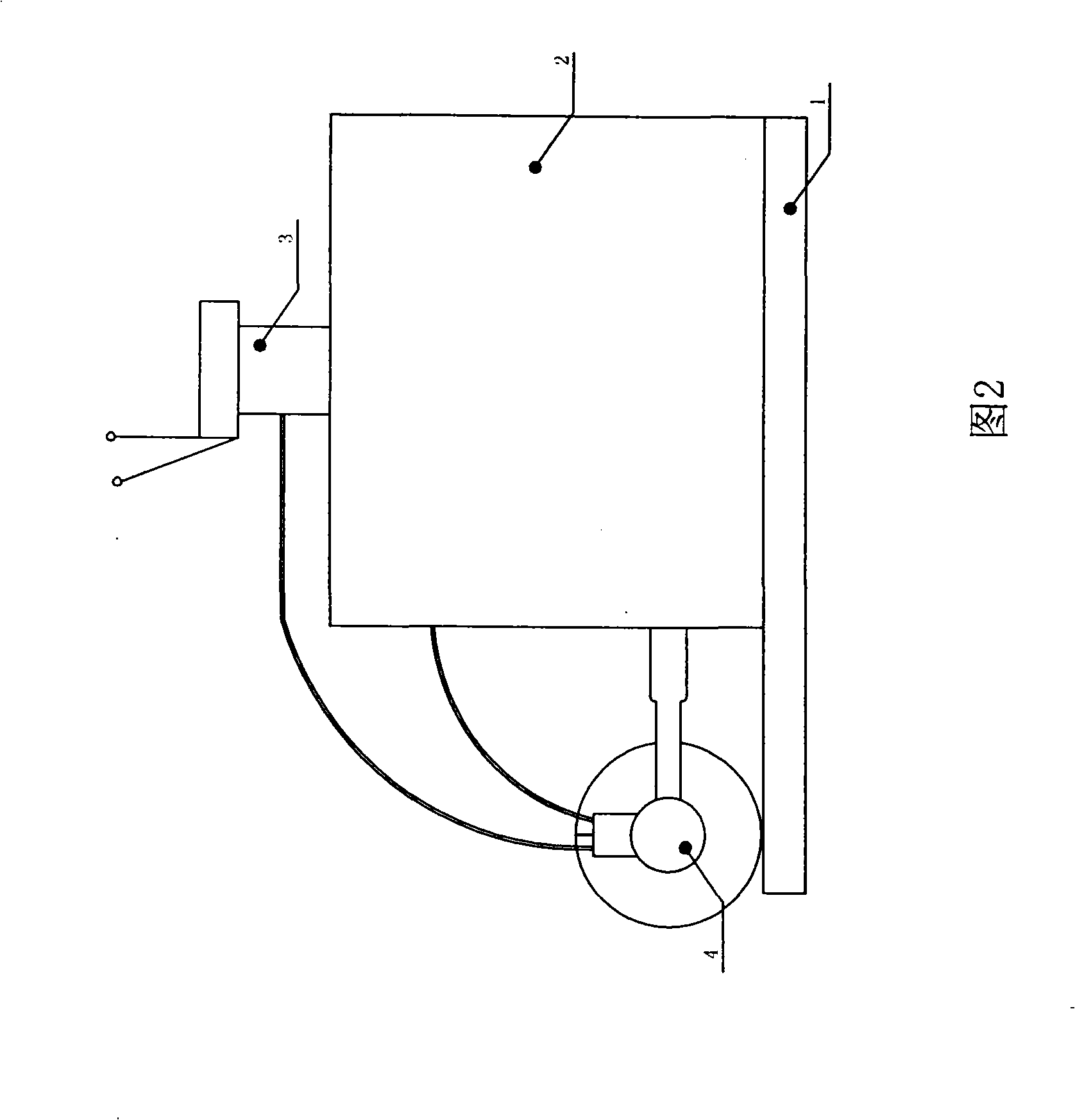

[0011] Such as figure 1 The hydraulic extubation device shown in and 2 is composed of a hydraulic system and an extubator. The hydraulic system is shown in Figure 2. The hydraulic oil tank 2 is fixed on the bracket 1. The oil outlet of the hydraulic oil tank is equipped with an oil pump 4, and the outlet of the oil pump is connected to distribute Distributor 3, the distributor communicates with the hydraulic cylinder 5, the arm of the hydraulic cylinder is equipped with an extubation frame 6, the extubation frame has an assembly hole, and is set on the cylinder arm through the assembly hole, there is a large steel pipe socket in the middle of the extubation frame, and the socket It is locked with the large steel pipe by the locking device 7, the locking device is an inclined iron, and the hydraulic station supplies 30mpa hydraulic oil. Oil is supplied up and down to the tube puller cylinder through the distributor to realize the up and down movement of the cylinder arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com