Ultra-thin stone and aluminum honeycomb composite modified epoxy adhesive and preparation thereof

An epoxy adhesive, ultra-thin technology, applied in the direction of adhesives, epoxy resin adhesives, polyurea/polyurethane adhesives, etc., can solve the problems of glass transition temperature lowering, affecting heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of polyurethane prepolymer

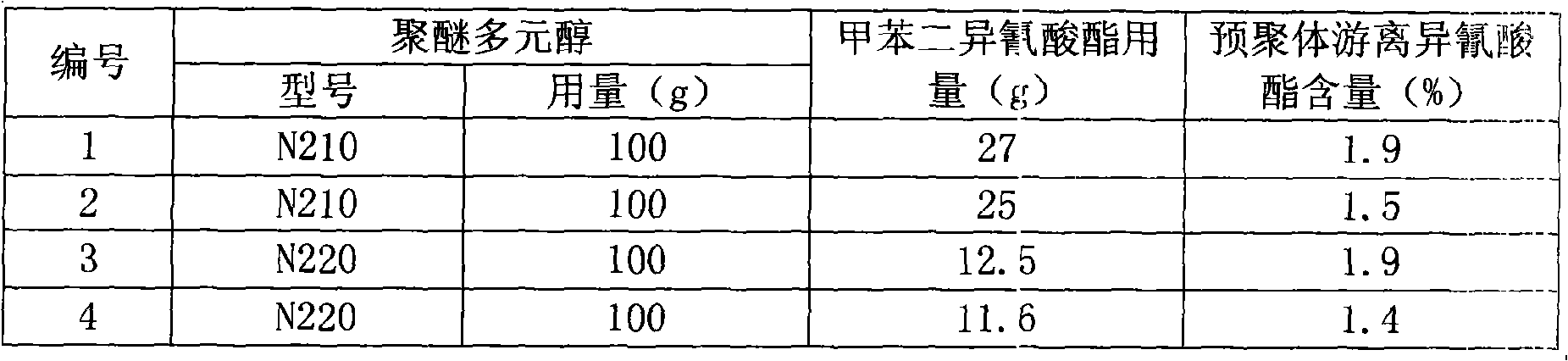

[0038] See Table 1 for the feed amount and free isocyanate group content of the prepolymer during the preparation of the polyurethane prepolymer.

[0039] The preparation of table 1 polyurethane prepolymer

[0040]

[0041] Preparation:

[0042] Add 100g of polyether polyol into a reactor equipped with a stirrer, dropping funnel, vacuum tube, and water bath heating device, heat up to 90°C, vacuumize for 2 hours, the vacuum degree is 0.092-0.095MPa, cool down to 60°C, Eliminate the vacuum, add TDI dropwise through the dropping funnel, react at 60°C for 1 hour, raise the temperature to 70°C for 1 hour, then raise the temperature to 85°C for 1 hour, drop to room temperature, and take samples to measure the free isocyanate groups of the prepolymer.

[0043] (2) Preparation of component A in modified epoxy adhesive

[0044] Ingredients: epoxy resin E-44 15g 6458 14g

[0045] Reactive diluent W-95 10g

[0046] Polyurethane ...

Embodiment 2

[0064] The ingredients of component A are:

[0065] Epoxy resin E-44 10g E-51 8g 6458 14g

[0066] Reactive diluent 622 6g 678 2g

[0067] Polyurethane prepolymer 19g

[0068] Inorganic powder filler Wollastonite powder 20g Quartz powder 10g Barite powder 11g

[0069] All the other are the same as embodiment 1

[0070] The preparation method is the same as that in Example 1, and the product is used for the composite of thin stone and aluminum honeycomb. The test results are shown in Table 2.

Embodiment 3

[0072] B component ingredients are:

[0073] Modified amine curing agent 38g accelerator DMP-30 5g coupling agent KH-560 4g

[0074] Glass flakes 8g

[0075] Inorganic powder filler Wollastonite powder 25g Talc powder 15g Barite powder 5g

[0076] All the other are the same as embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com