Normal temperature cured type tetrafluoroethylene fluorocarbon coating resin and preparation thereof

A tetrafluoroethylene and fluorocarbon coating technology, applied in the coating and other directions, can solve the problems of affecting the aging resistance of coatings, difficult to achieve alternating copolymerization, etc., and achieve the effects of easy automation, improved service life, and improved weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

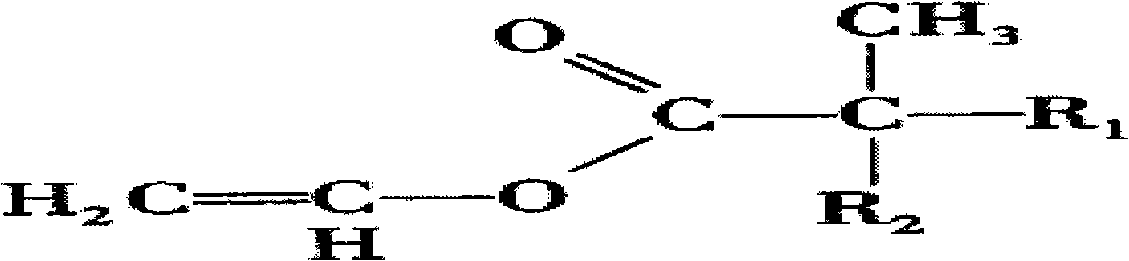

Method used

Image

Examples

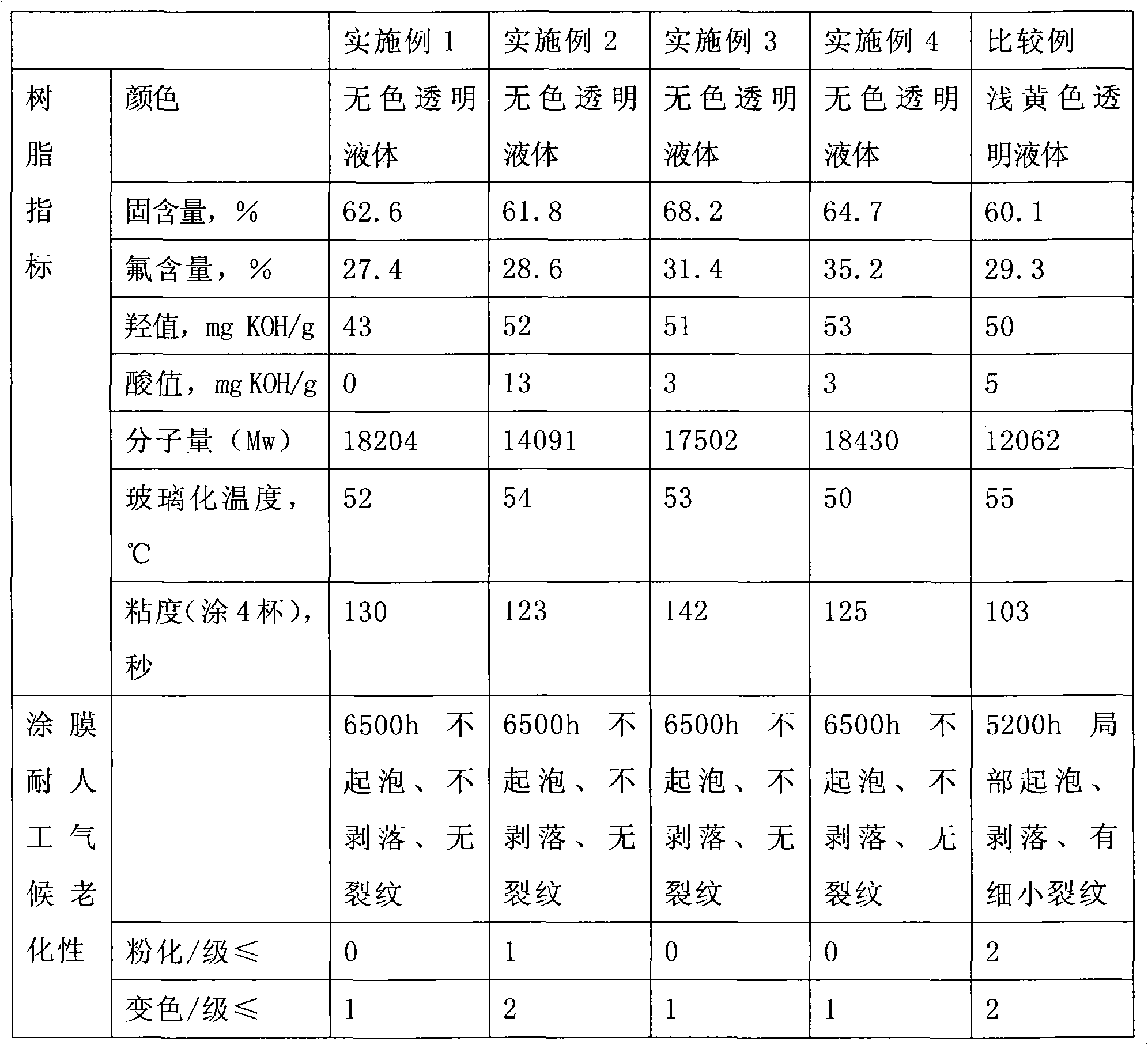

Embodiment 1

[0036] Add 250 grams of vinyl tertiary carbonate VV9, 260 grams of VV10, 75 grams of ethylene glycol monopropenyl ether, 250 grams of butyl acetate, and 235 grams of methyl isobutyl ketone into the small dissolution tank, start stirring and mixing, and slowly Add 14 grams of initiator (azobisisobutyronitrile), and stir to dissolve it. Vacuumize the 2.5-liter polymerization kettle, replace N2, and then vacuumize. Use the vacuum in the polymerization kettle to suck the mixed solution of monomer and initiator into the polymerization kettle. And start stirring, after the temperature drops to -8°C, open the tetrafluoroethylene monomer tank valve and add 390 grams of tetrafluoroethylene monomer. Raise the temperature of the polymerization kettle through the control system, control the reaction temperature to 80° C., and the reaction pressure to 1.8 MPa. After 18 hours of reaction, the sampling is qualified, and the temperature is lowered to normal temperature. Stop stirring, and re...

Embodiment 2

[0039] 25 grams of tertiary vinyl carbonate VV9425 grams, 90 grams of ethylene glycol monopropenyl ether, 45 grams of undecylenic acid, and 510 grams of butyl acetate are added to the dissolving tank, start stirring and mixing, and slowly add initiator (even Azodiisobutyronitrile) 11 grams, stirred to dissolve it. Vacuumize the 2.5-liter polymerization kettle, replace N2, and then vacuumize. Use the vacuum in the polymerization kettle to suck the mixed solution of monomer and initiator into the polymerization kettle. And start stirring, after the temperature drops to -10°C, open the valve of the tetrafluoroethylene monomer tank and add 450 grams of tetrafluoroethylene monomer, and the reaction pressure is 2.0 MPa. The temperature of the polymerization tank was raised by the control system, and the reaction temperature was controlled to 75°C. After reacting for 15-18 hours and sampling qualified, cool down to normal temperature. Stop stirring, and recover the incompletely rea...

Embodiment 3

[0042] Add 220 grams of tertiary vinyl carbonate VV9, 210 grams of VV10, 90 grams of ethylene glycol monopropenyl ether, 12 grams of undecylenic acid, 300 grams of butyl acetate, and 80 grams of methyl isobutyl ketone into the dissolution tank, and start Stir and mix, slowly add 10 grams of initiator (azobisisobutyronitrile) under stirring, and stir to dissolve it. Vacuumize the 2.5-liter polymerization kettle, replace N2, and then vacuumize. Use the vacuum in the polymerization kettle to suck the mixed solution of monomer and initiator into the polymerization kettle. And start stirring, after the temperature drops to -18°C, open the tetrafluoroethylene monomer tank valve and add 500 grams of tetrafluoroethylene monomer. Raise the temperature of the polymerization tank through the control system, control the reaction temperature to 70±2°C, and the reaction pressure to 2.6MPa. After reacting for 15-18 hours and sampling qualified, cool down to normal temperature. Stop stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com