Interface between directly-heated metal capillary chromatography column and gas chromatograph

A technology of capillary chromatographic column and gas chromatograph, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as electron capture detectors and hydrogen flame ionization detectors of some manufacturers that cannot work normally, and achieve functional The effect of low consumption, small heat capacity and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

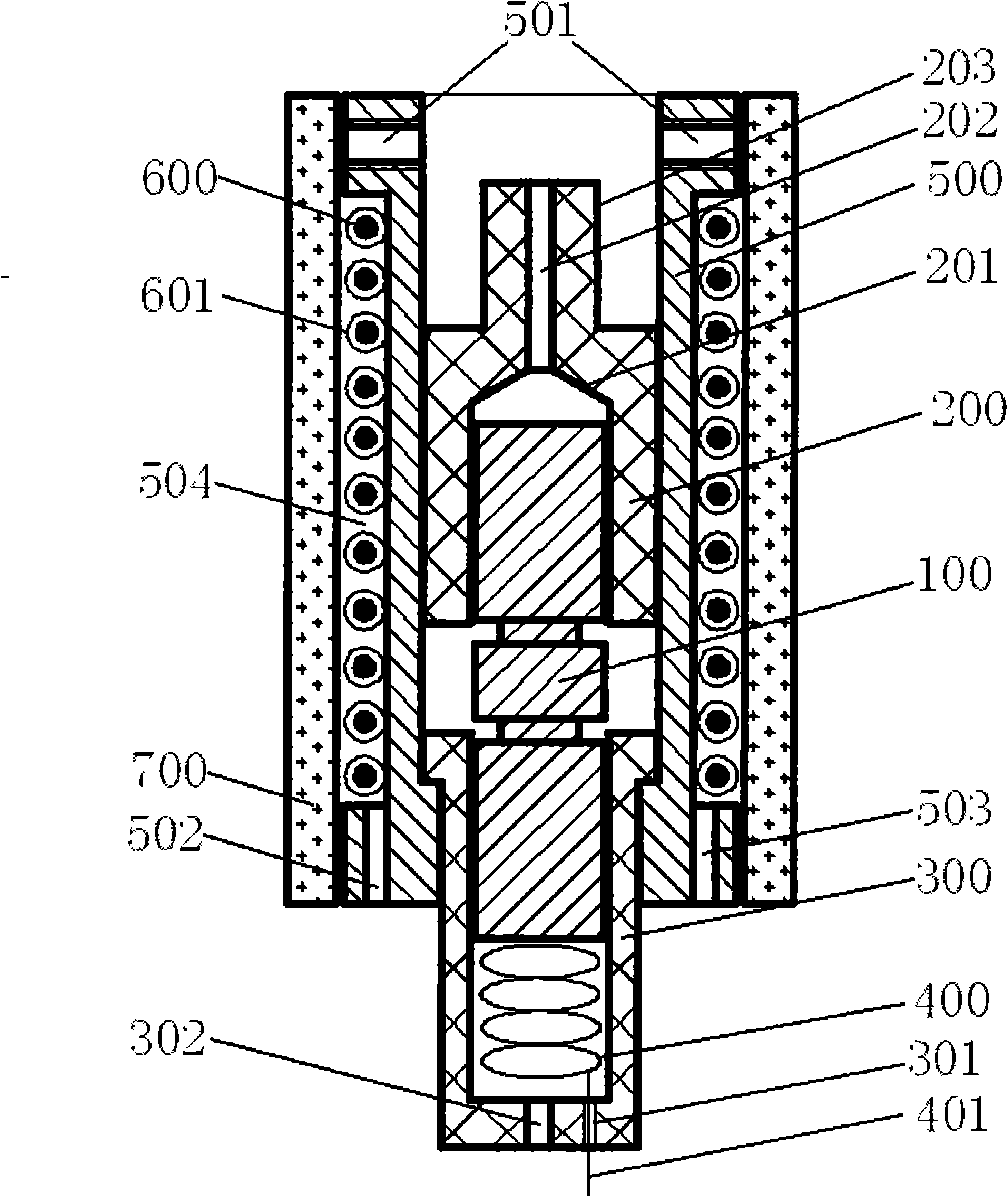

[0020] see figure 1 As shown, the present invention is a schematic diagram of the interface structure used to connect the metal capillary chromatographic column to the Agilent 6890N gas chromatograph inlet / detector.

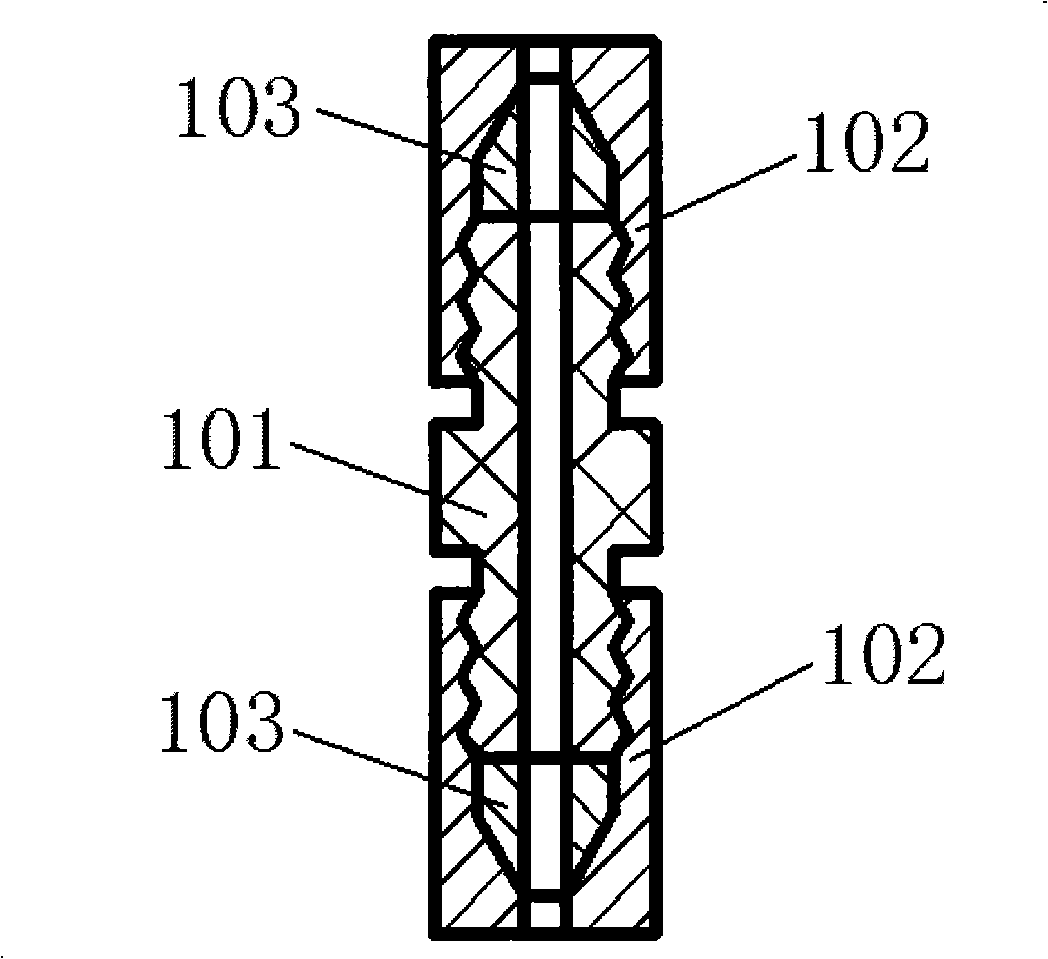

[0021] This interface connects one end of the metal capillary column with a section of fused silica capillary column through a micro two-way 100. The micro two-way 100 is made of metal material and sealed with a metal ferrule 103 to ensure good electrical contact. In the micro two-way 100 There are upper and lower high temperature resistant insulating sleeves 200 and 300 respectively at the upper and lower ends of the upper and lower ends. made of insulating material. A section of spring-shaped metal wire 400 is clamped between the miniature two-way and its lower end high-temperature-resistant insulating sleeve 300 to act as an electrode lead 401 for heating voltage on the chromatographic column. The high temperature resistant insulating sleeve 200 on the upper...

Embodiment 2

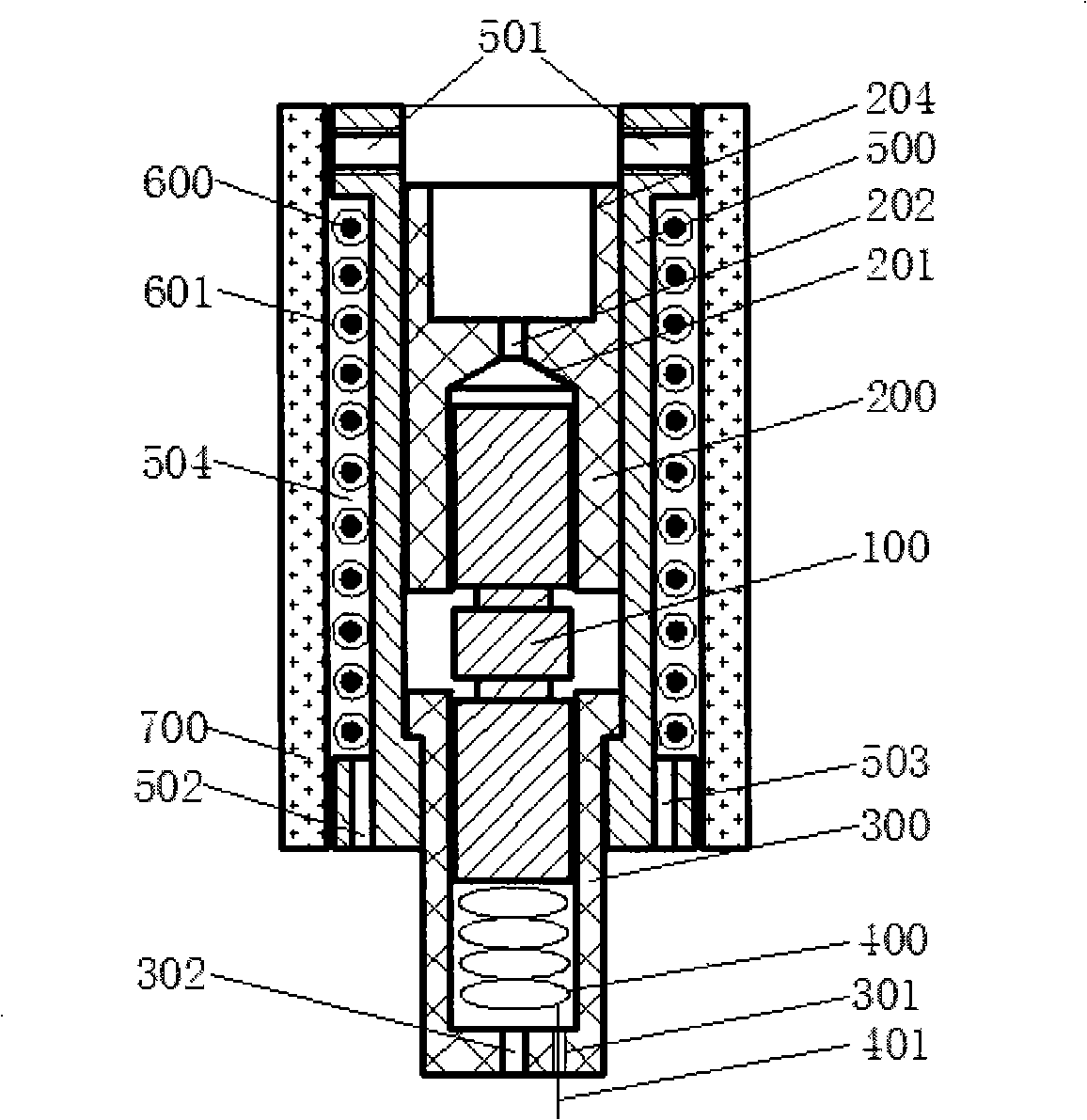

[0025] For the present invention figure 1 The shape of the upper high-temperature-resistant insulating sleeve 200 is slightly modified, and the top of the upper high-temperature-resistant insulating sleeve 200 is set as a columnar groove 204, so that it can be screwed with the column joint screw of the inlet / detector of the Varian 3800 gas chromatograph. The cap is adapted, and the interface of the invention can be used for the connection between the metal capillary chromatographic column and the Varian 3800 gas chromatograph inlet / detector.

[0026] The interface between direct heating metal capillary chromatographic column and Varian 3800 gas chromatograph, the interface is a cylindrical structure, including micro two-way 100, upper high temperature resistant insulating sleeve 200, lower high temperature resistant insulating sleeve 300, thin-walled metal sleeve 500, heating wire 600 and insulation layer 700,

[0027] The insulation layer 700 is sleeved on the outer side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com