Insulation method for conductive liquid medium in short section electrical connection of instrument while drilling

A technology of conductive liquid medium, instrument while drilling, applied in the direction of connection, communication with liquid, flexible/rotatable wire connector, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

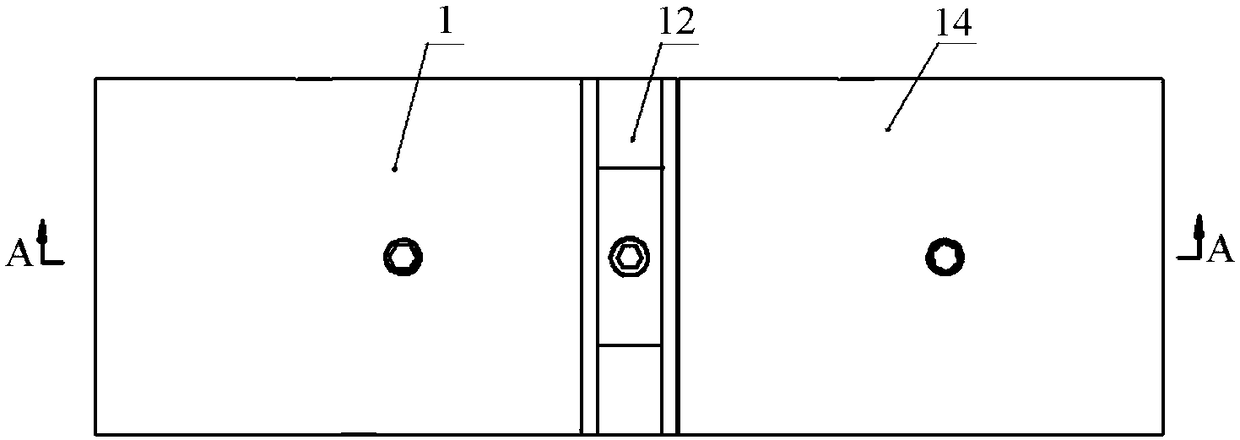

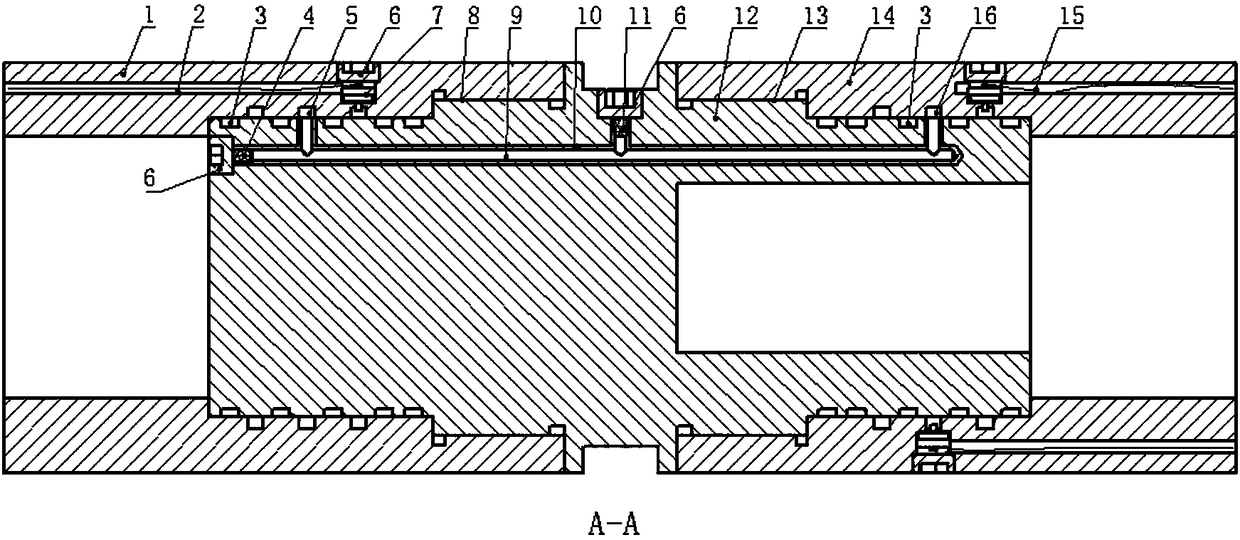

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] Such as figure 1 and 2 As shown, the insulation method of the conductive liquid medium in the electrical connection of the short section of the instrument while drilling, the specific steps are as follows:

[0015] Step 1. The joint body 12 is provided with three axial holes with a diameter of 5-6 mm on the top end surface; the bottom of the axial holes is closed, and three radial holes are opened on the side wall; Inject the fusible polytetrafluoroethylene 10 into the hole; after the fusible polytetrafluoroethylene is solidified, release the seals of all the radial holes, and the fusible polytetrafluoroethylene material in each axial hole has a hole diameter of 3-4mm axial conductive liquid channel 9; the axial conductive liquid channel 9 is arranged coaxially with the corresponding axial hole, and the depth is 2-3mm smaller than the depth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com