Bidirectional cooling LED apparatus

A technology of light-emitting diodes and two-way heat dissipation, which is applied to lighting devices, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems such as damage to light-emitting diode chips, single heat conduction path, and inability to dissipate heat in a timely manner. Avoid damage and increase the effect of heat dissipation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the bidirectional heat dissipation LED device of the following embodiments, the heat generated by the LED chip can be dissipated to the heat dissipation substrate and the outside through the main body portion and the extension portion of the heat dissipation material respectively. Furthermore, heat dissipation fasteners can be added to fasten the extension of the heat dissipation material and the heat dissipation substrate, so that the light emitting diodes, the heat dissipation material, and the heat dissipation substrate are tightly bonded to increase heat dissipation efficiency.

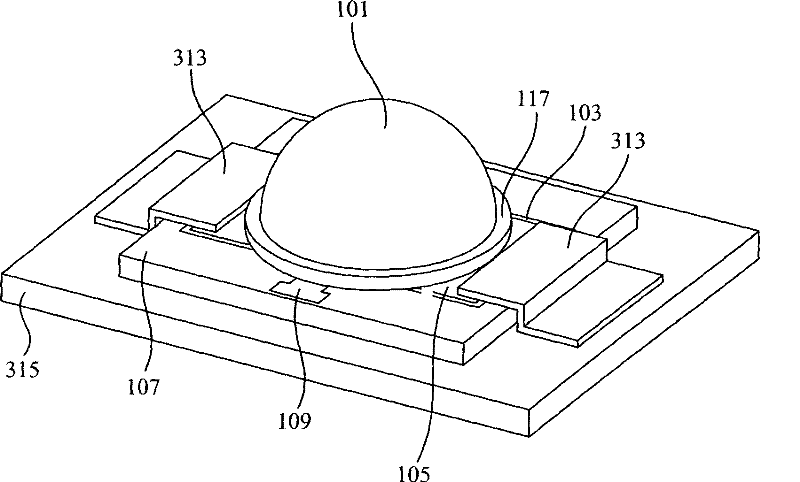

[0025] Please also refer to figure 1 as well as figure 2 , which are respectively a perspective view and a cross-sectional view of a bidirectional heat dissipation LED device according to an embodiment of the present invention. The bidirectional heat dissipation LED device includes a heat dissipation material 105 and an LED chip 211 disposed on the heat dissipation material 105 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com