Assembly method for reducing timing error of car engine

A technology of automobile engine and assembly method, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems such as phase errors, and achieve the effect of reducing timing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

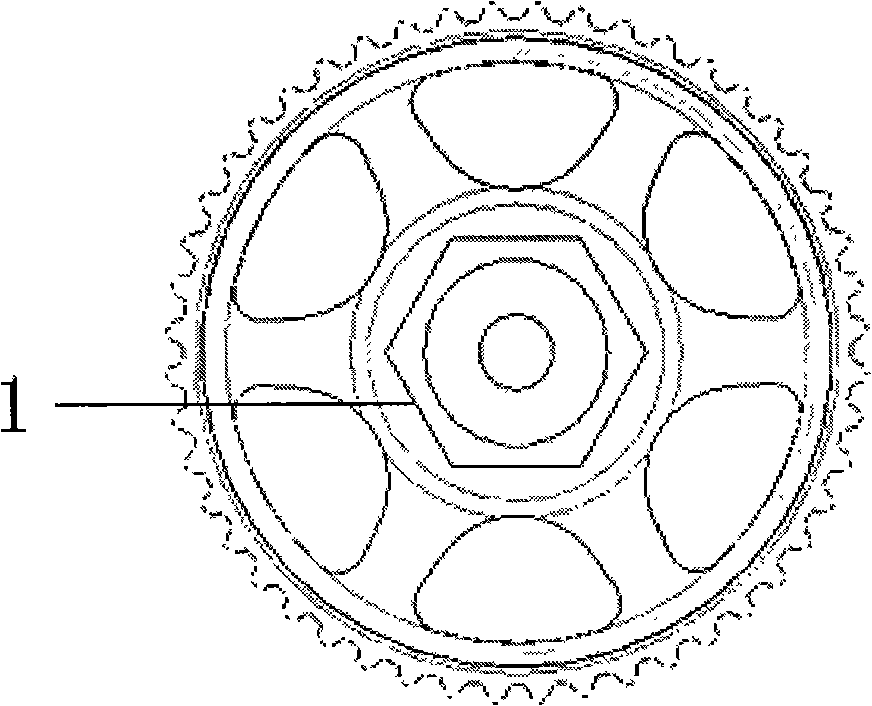

[0012] The assembly method is, after fixing the crankshaft and camshaft, assemble the crankshaft, camshaft timing gear, tensioner and idler, install the timing belt, and finally tighten the bolts of the camshaft timing gear, after tightening the camshaft timing gear During the bolting process, ensure that the timing gear and the camshaft do not rotate relative to each other.

[0013] As shown in the figure, the non-relative rotation between the timing gear and the camshaft is achieved by the following method: the camshaft timing gear has an extra hexagonal flange surface 1, and when tightening the bolts of the camshaft timing gear, use the timing tool to pass through The timing gear is fixed by the hexagonal flange surface to ensure that the camshaft timing gear and the camshaft do not rotate relative to each other during the tightening of the camshaft timing gear bolts, thereby reducing the timing error.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com