Automobile engine wheel train drive system

An automotive engine and drive system technology, applied in engine components, machines/engines, mechanical equipment, etc., to solve problems such as impact, overall engine performance degradation, power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

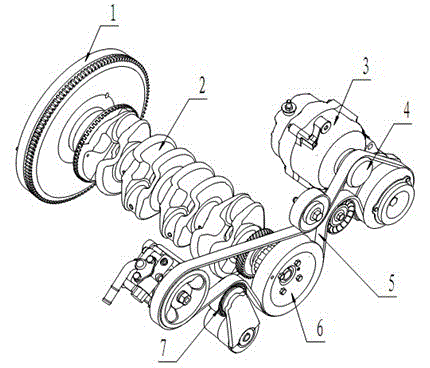

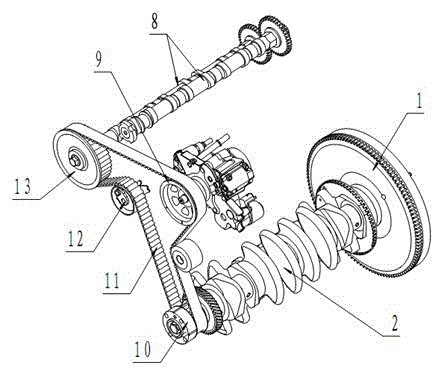

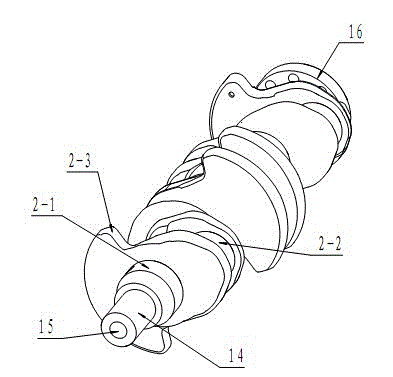

[0022] See Figure 1, figure 2 , image 3 , the present invention includes a crankshaft 2, a timing wheel drive pulley 10, an auxiliary device wheel drive pulley 6 and a dual-mass flywheel 1, and the crankshaft 2 is provided with a main journal 2-1, a bell crank 2-2 and a balance Block 2-3, the timing wheel train drive pulley 10 is installed at the bolt mounting hole 15 of the timing wheel train drive pulley mounting journal at the front end of the crankshaft through bolts, and the dual-mass flywheel 1 is installed at the rear end of the crankshaft 2 through bolts. On the dual-mass flywheel mounting disc 16, timing belt 11 is wound on each pulley of the timing wheel train, and they form the timing train (such as figure 2 shown); the auxiliary device wheel drive pulley 6 is installed on the front end of the timing wheel drive pulley 10 through bolts, and the auxiliary device wheel belt 5 is wound on each pulley of the auxiliary device wheel train, which form the auxiliary dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com