Firing jig and method for manufacturing honeycomb structured body

A technology for a honeycomb structure and a manufacturing method, which can be applied in applications, household appliances, ceramic products, etc., can solve problems such as increased operating costs and coating peeling, and achieve the effects of reducing operating costs and preventing unstable firing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0061] Next, a first embodiment, which is one embodiment of the present invention, will be described with reference to the drawings.

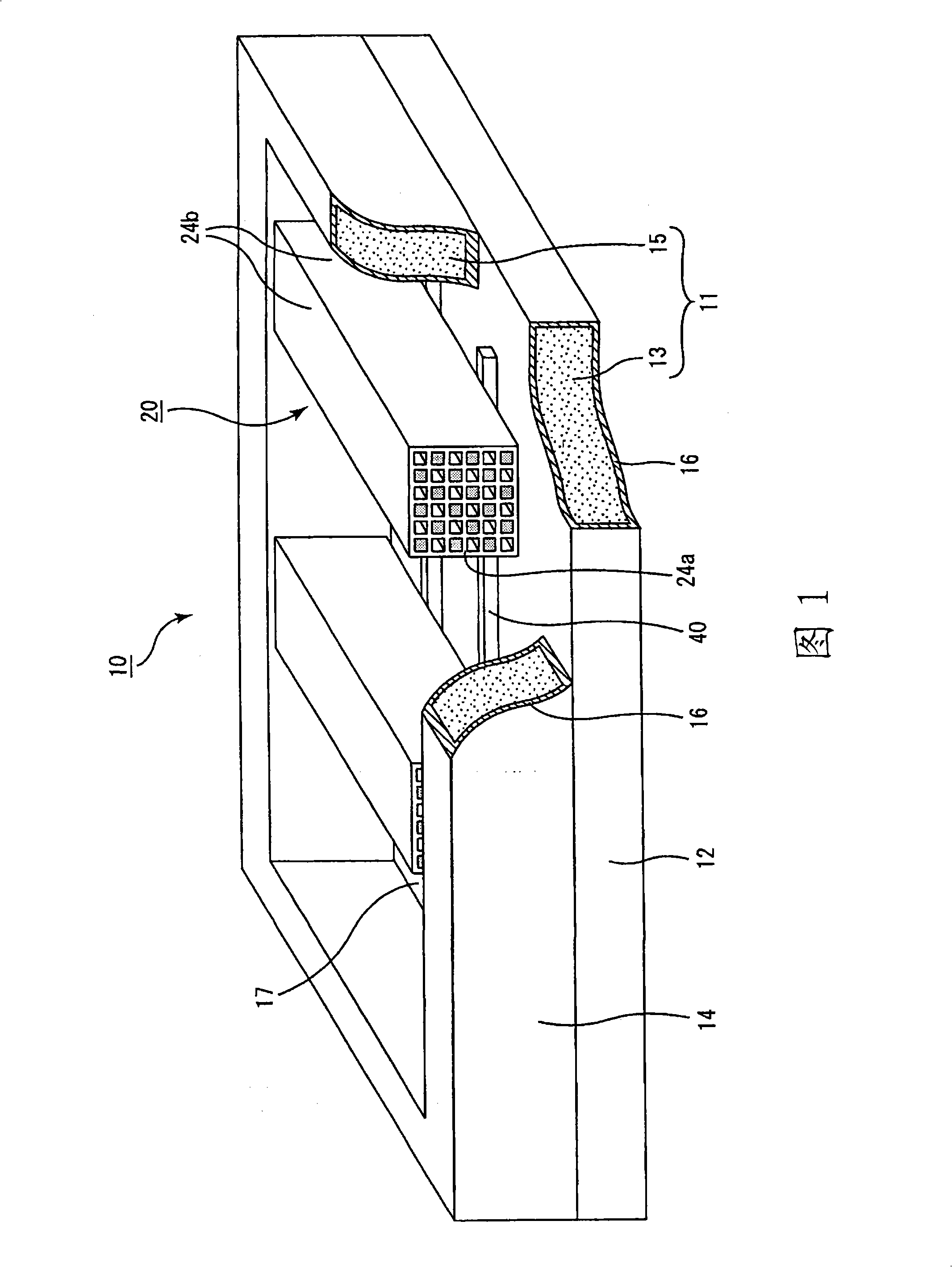

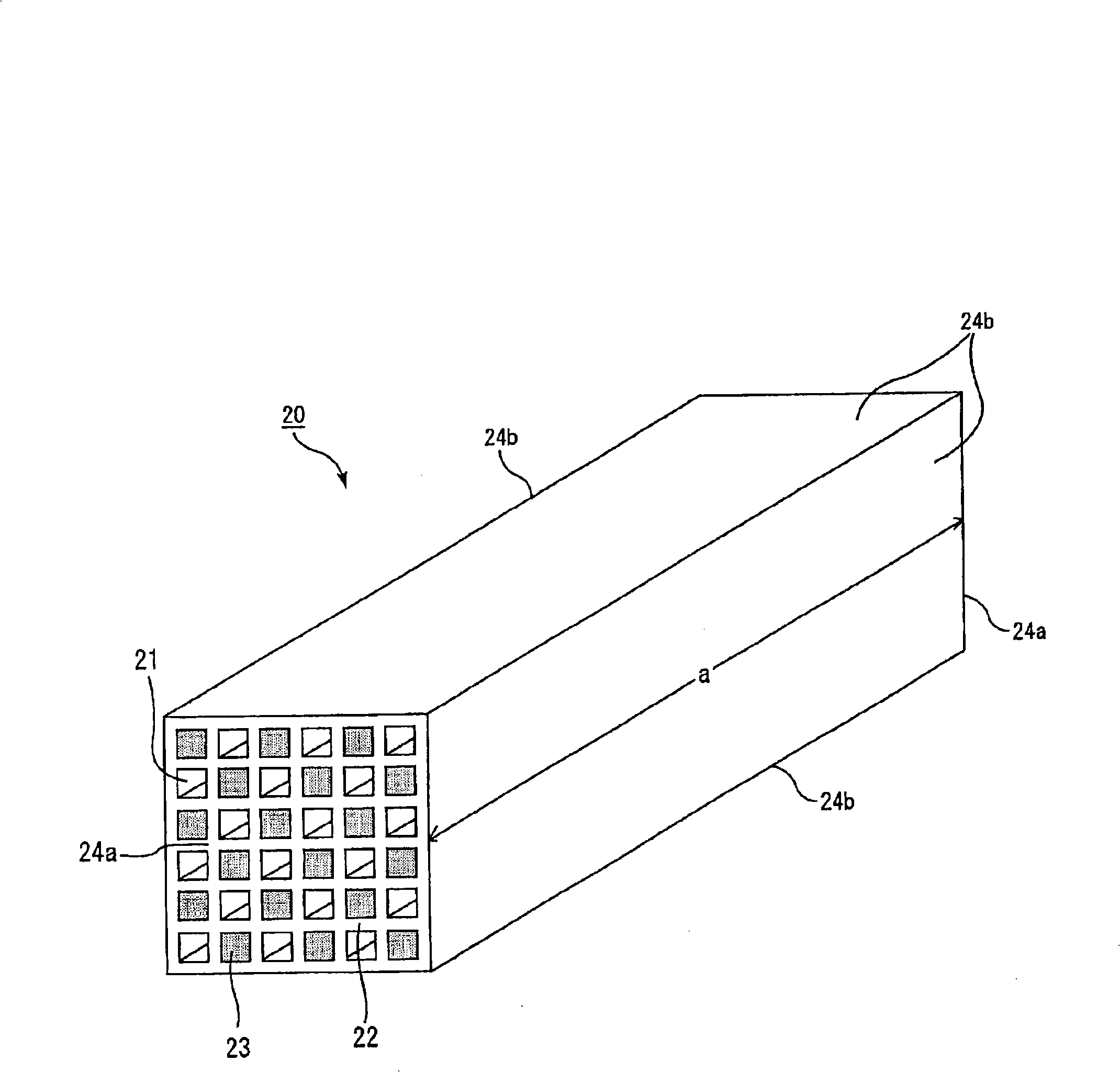

[0062] Fig. 1 is a partially cutaway perspective view schematically showing a firing jig according to a first embodiment of the present invention.

[0063] The firing rack 10 is composed of a bottom plate 12 and a frame material 14, and the frame material 14 is placed on the bottom plate 12 so that both are integrated. The frame material 14 is fixed to the base plate 12 by fitting the protrusions formed on the lower surface of the frame material 14 and the recesses formed on the upper surface of the base plate 12 to each other.

[0064] The bottom plate 12 is composed of a carbon base material 13 and a coating layer 16 formed on the surface of the base material 13, and the frame material 14 is composed of a carbon frame base material 15 and a coating layer 16 formed on the surface of the frame base material 15. . In the firing jig 10 shown in...

Embodiment 1

[0105]On the surface of a box-shaped frame with an open upper part made of carbon (DSG-332 manufactured by SEC Co., Ltd.) consisting of a bottom base material and a frame base material, on the mounting surface of the honeycomb formed body of the base base material and the surface of the frame base material On the surface, a dense SiC coating composed of SiC is formed by chemical vapor infiltration (CVI). Place the above-mentioned base material in the reactor, use methyltrichlorosilane as the gas phase raw material, let the gas phase raw material flow into the reactor with a temperature of 1500°C and reduce the pressure, and precipitate SiC with a thickness of about 90 μm, thereby performing SiC Coating formation. Precipitation of SiC is performed once.

Embodiment 2

[0107] 60 g of silicon carbide powder, 3 g of tetrabutoxytitanium, 17 g of silicone resin, and 20 g of xylene were kneaded to prepare a SiC layer forming material. On the surface of a box-shaped frame with an open upper part made of carbon (DSG-332 manufactured by SEC Co., Ltd.) consisting of a bottom base material and a frame base material, on the mounting surface of the honeycomb formed body of the base base material and the surface of the frame base material On top, the SiC coating material (spray weight: 25 g) was sprayed with a spray gun, and dried at 80° C. for 20 minutes and at 230° C. for 20 minutes using a dryer, thereby forming a SiC coating on the surface of the frame.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com