Photocatalysis oxidation method for treating waste water of anthraquinone dye

A technology for photocatalytic oxidation and anthraquinone dyes, which is applied in the fields of energy wastewater treatment, natural water treatment, chemical instruments and methods, etc. High removal rate, high catalyst activity, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

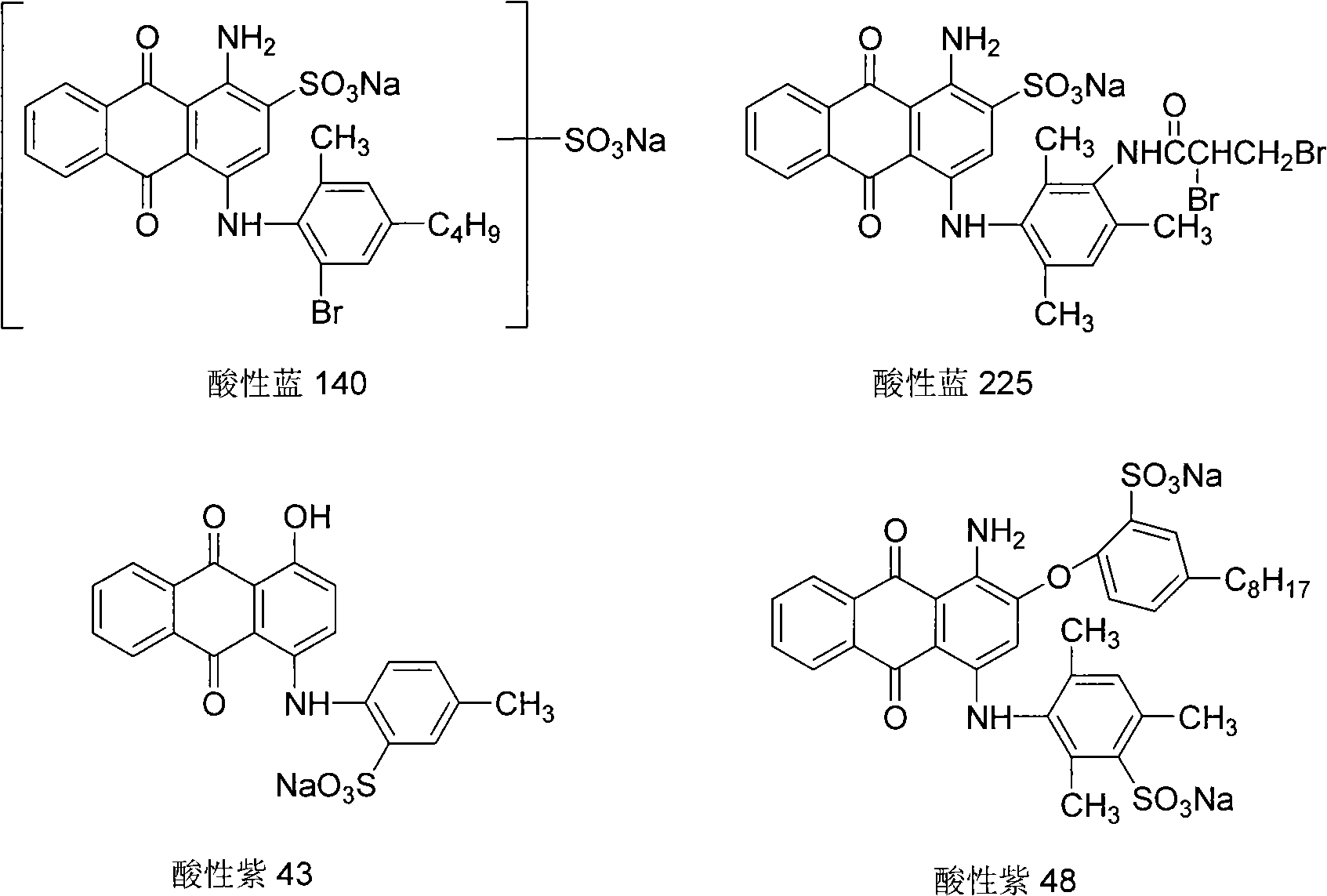

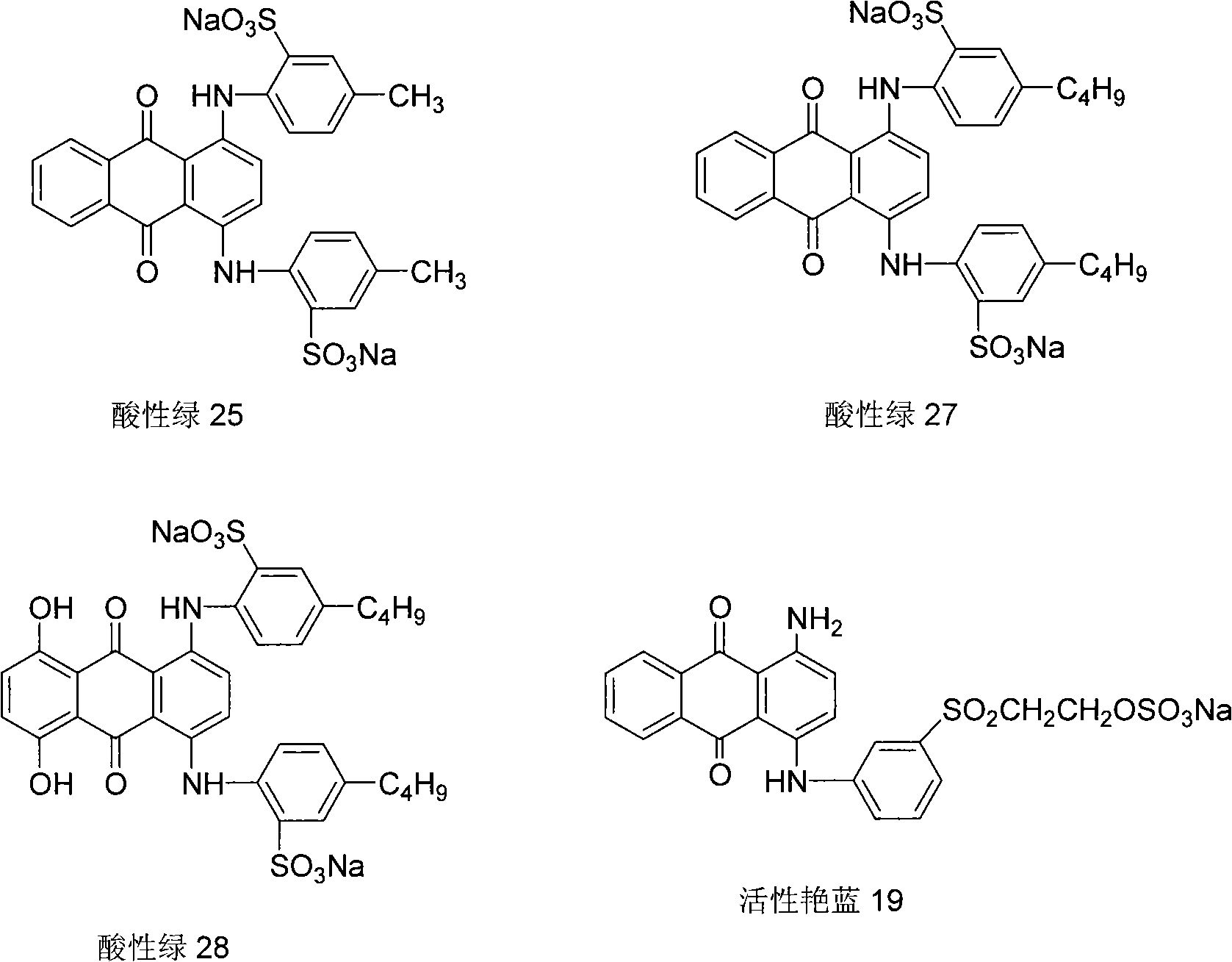

Image

Examples

Embodiment 1

[0022] First use HCl or NaOH to adjust the pH value of the dye wastewater so that 1≤pH≤12, then add 10mL of 50-150mg / L anthraquinone dye AB80 aqueous solution into a 25mL glass test tube, then add catalyst into the system, and blow 15mL at a time air, sealed, and placed in an intelligent light incubator for photodegradation, the light intensity is 5320-5520Lux, and the light time is 1-30 days. The removal rate of AB80 after the reaction is shown in Table 1.

[0023] Table 1 The results of photocatalytic oxidation treatment of AB80 dye wastewater

[0024] dye concentration

[0025] 100mol%K 2 SO 4

[0026] Mole % is the ratio of the amount of catalyst to the amount of dye.

Embodiment 2

[0028] According to the operation steps of the above-mentioned Example 1, the pH value of the anthraquinone dye AB80 wastewater was adjusted to 2.6 with HCl, and then 30 mL of 50-150 mg / L dye aqueous solution was added to a 50 mL glass test tube, and 20 mL of air was blown in at one time, followed by adding 80 mol% FeCl 3 / 80mol%NaNO 2 The catalyst (mol% is the ratio of the amount of catalyst to the dyestuff), sealed, put into an intelligent light incubator for light, light intensity 5320-5520Lux, light 1-30 days, TOC removal rate is shown in Table 2.

[0029] Table 2 TOC removal results of photocatalytic oxidation treatment of AB80 dye wastewater

[0030] dye concentration

Embodiment 3

[0032]According to the operation steps of the above-mentioned Example 1, the pH value of the anthraquinone dye wastewater was adjusted to 2.6 with HCl, and then 10 mL of 50 mg / L anthraquinone dye aqueous solution was added to a 25 mL glass test tube, and 15 mL of air was blown in at one time, and then 80 mol% FeCl was added 3 / 80mol%NaNO 2 The catalyst (mol% is the ratio of the amount of catalyst to the dyestuff), sealed, put into an intelligent light incubator for light, light intensity 5320-5520Lux, light 1-30 days, the results are shown in Table 3.

[0033] Table 3 The results of photocatalytic oxidation treatment of other anthraquinone dye wastewater

[0034]

[0035] Acid Blue 225

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com