Aluminum alloy energy saving window or door system

An aluminum alloy, door and window technology, applied in the arrangement of windows/doors, wing sashes, parallel glass structures, etc., can solve problems such as the imperfect combination of hinges and profiles, lack of unified design specifications, and reduced air tightness of the entire window. , to achieve the effect of improving the overall air tightness and thermal insulation performance, improving the air tightness and thermal insulation performance, and improving the waterproof performance.

Inactive Publication Date: 2008-12-03

谢光

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] 4) In the no-pressure state, the water in the profile cavity is difficult to discharge due to the expansion force, and water leakage is easy to occur;

[0007] 5) There is no uniform design specification for profiles and hardware manufacturers, so that the hinges interspersed with the sealing strips cannot be perfectly combined with the profiles, forming gaps, resulting in a decrease in the airtightness of the entire window and poor energy-saving effects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

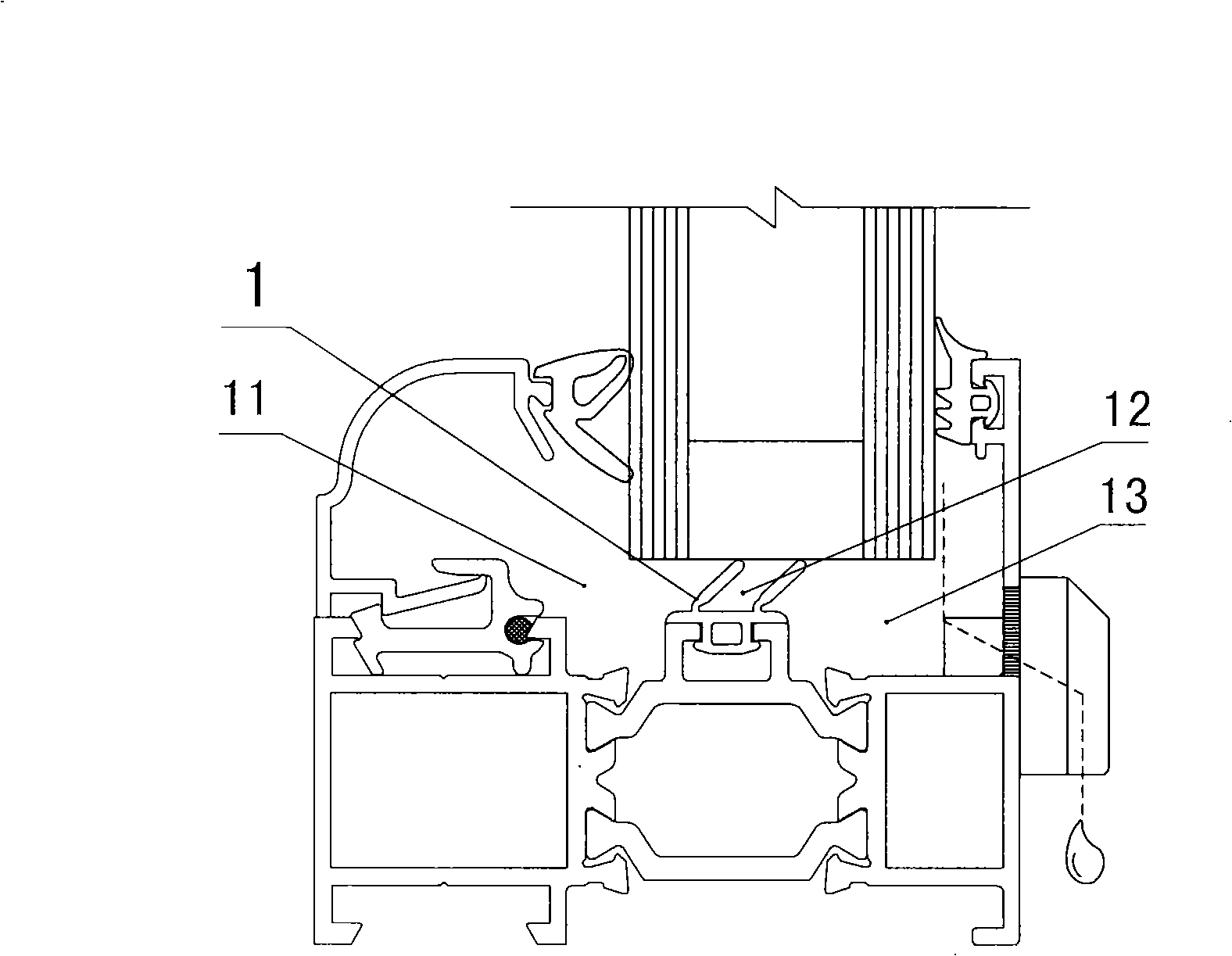

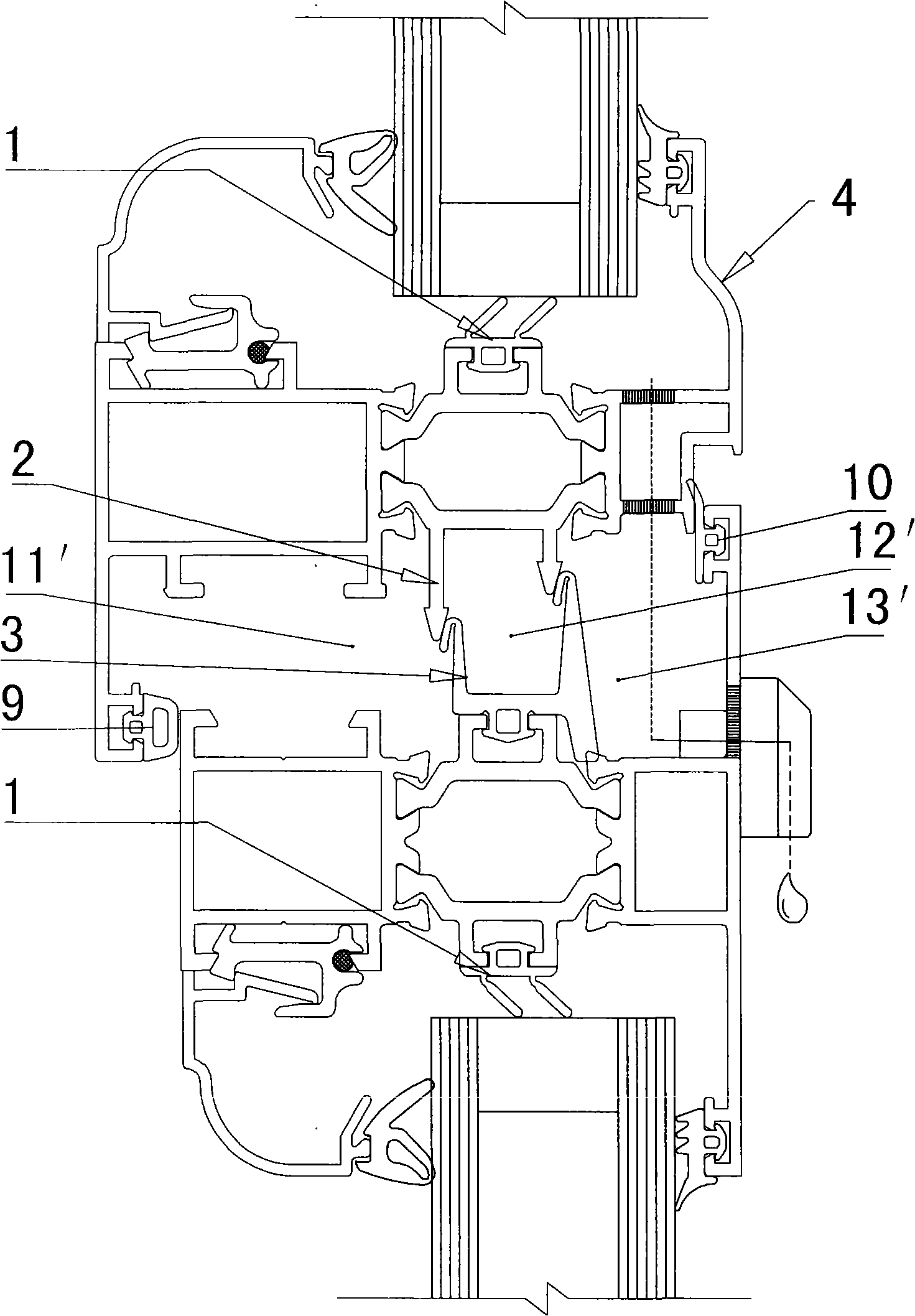

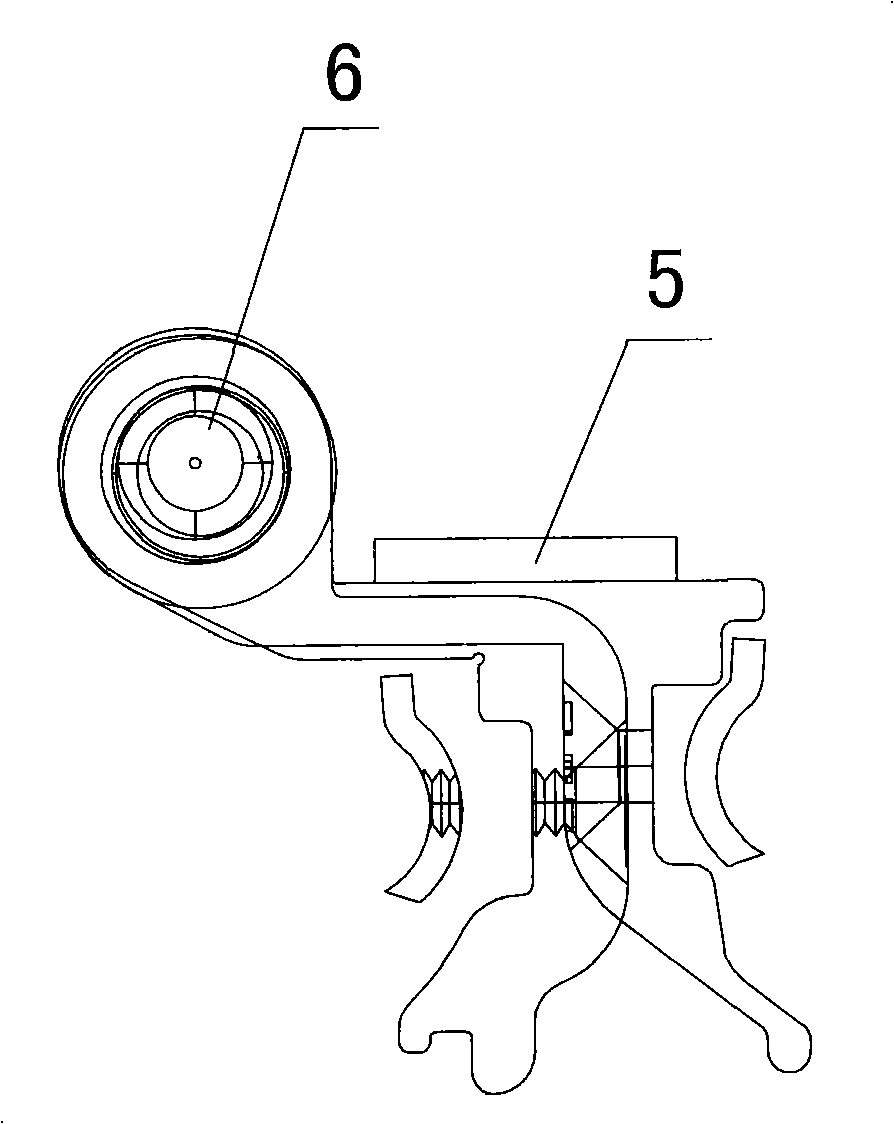

The invention discloses an aluminum alloy energy-saving door and window system. Heat insulation rubber strips are added between the section material of a window frame and a sash, and an air cavity of hollow glass; thereby the gas among the hollow glass, the window frame and the sash is blocked off, and the space is divided into three air cavities so as to form a cold and thermal bridge multi-cavity structure; the heat insulation rubber strips between the window frame and the sash, and equal pressure sealing rubber strips receptively adopt high low rail cold and thermal bridge structures, and the space is divided into three air cavities by matching window frame side pressing rubber strips and sash side pressing rubber strips, thereby a cold and thermal bridge multi-cavity structure is formed. The section material outside the sash is a step-shaped structure, the air cavity of hollow glass is positioned on the identical line with a heat insulation chamber of the window frame, a sealing gasket is additionally arranged on the upper side of the hinge of the sash in advance, a water drainage cap of the window frame is a drainage type water drainage cap, and parallel flow guiding pieces which are arranged at intervals are arranged at the water outlet of the water drainage cap. The door and window system has the advantage that the heat preservation, waterproof and sound-insulation performances of an external window of a building can be greatly improved.

Description

technical field [0001] The invention relates to a door and window system in the construction field, in particular to an aluminum alloy energy-saving door and window system. Background technique [0002] At present, the doors and windows used in construction projects require energy saving of 50% and 65% in the country and various regions, and heat preservation and energy saving are taken as an important assessment index for the performance of doors and windows. However, ordinary aluminum alloy doors and windows have large auxiliary radiation and conduction coefficients, and the thermal insulation performance belongs to the 5th to 6th level of the international GB / T 8484-2002, and the thermal insulation performance and effect are poor. The specific analysis is as follows: [0003] 1) The gap between the aluminum alloy profile and the glass is prone to convection; [0004] 2) The cross-section of the equal-pressure rubber strip between the frame and the sash is small; [0005...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E06B3/36E06B3/67E06B3/673E06B7/22E06B7/14

Inventor 谢光胡延庭

Owner 谢光

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com