Process for preparing olefin hydrocarbon and light aromatic hydrocarbon with poor oil in high limit

A technology of inferior oil and processing technology, used in the petroleum industry, refined hydrocarbon oil, cracking and other directions, can solve the problems of long process flow, severe losses, and coking diesel cannot be sold as commercial oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The present invention will be further described below with specific examples and comparative examples.

[0019] The percentages in the following comparative examples and examples are weight percentages unless otherwise specified.

Embodiment 1

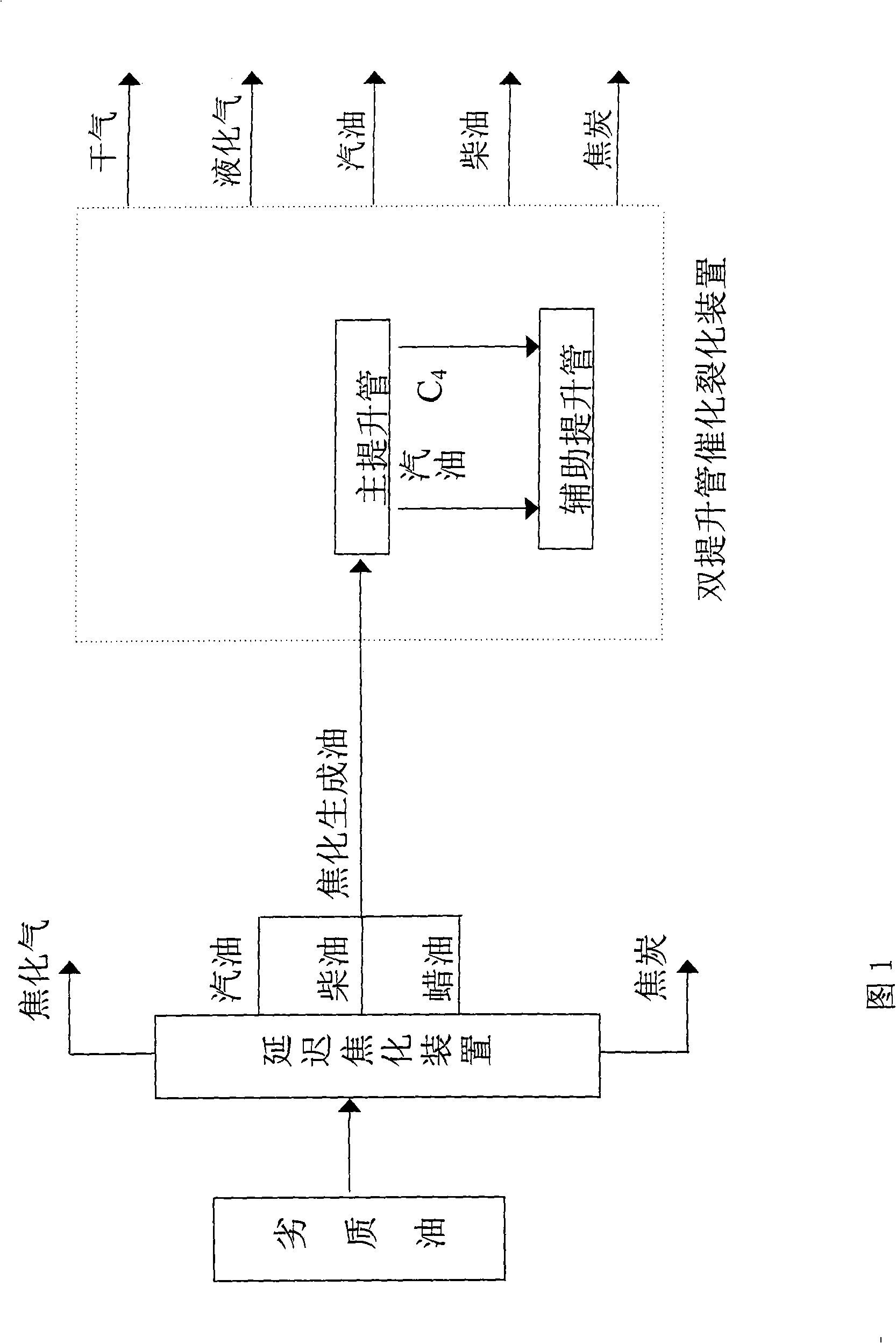

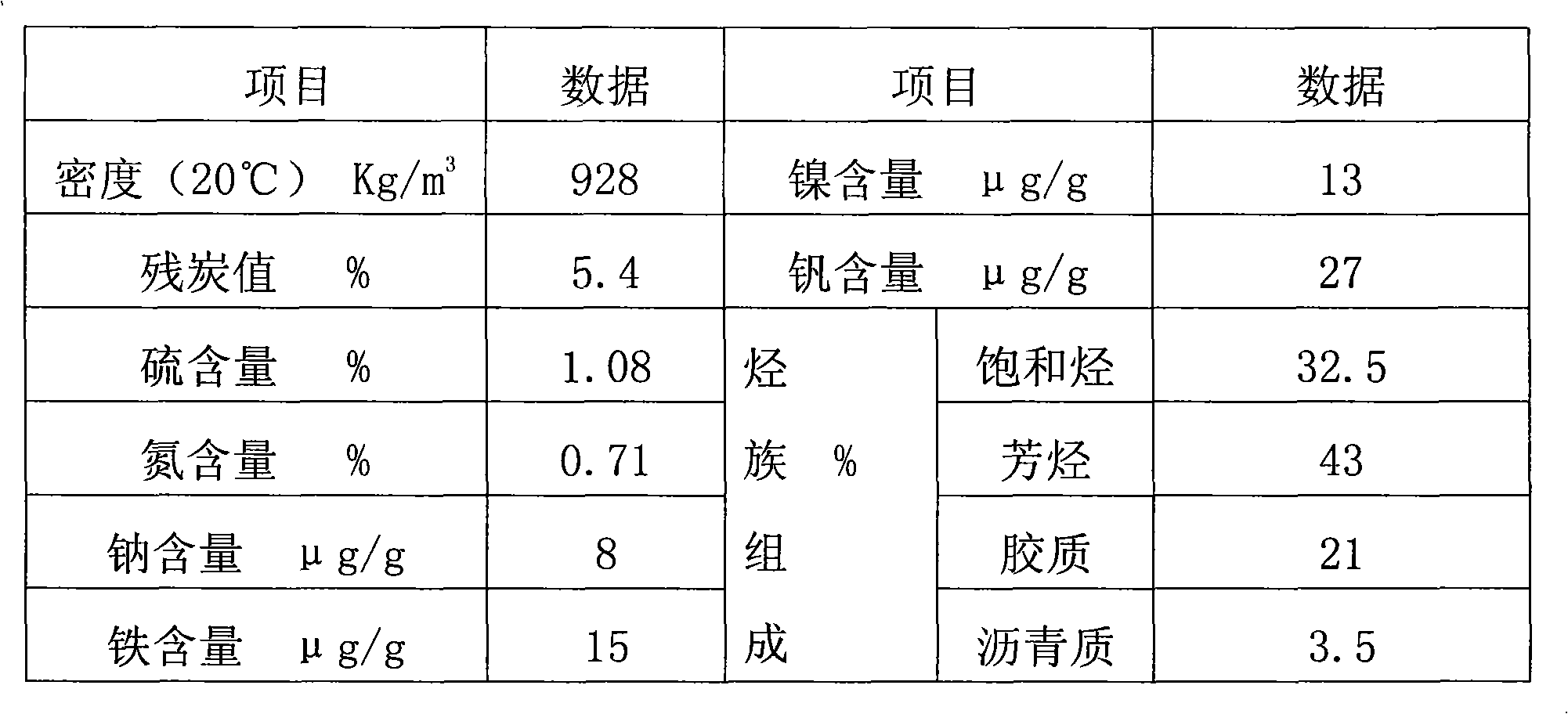

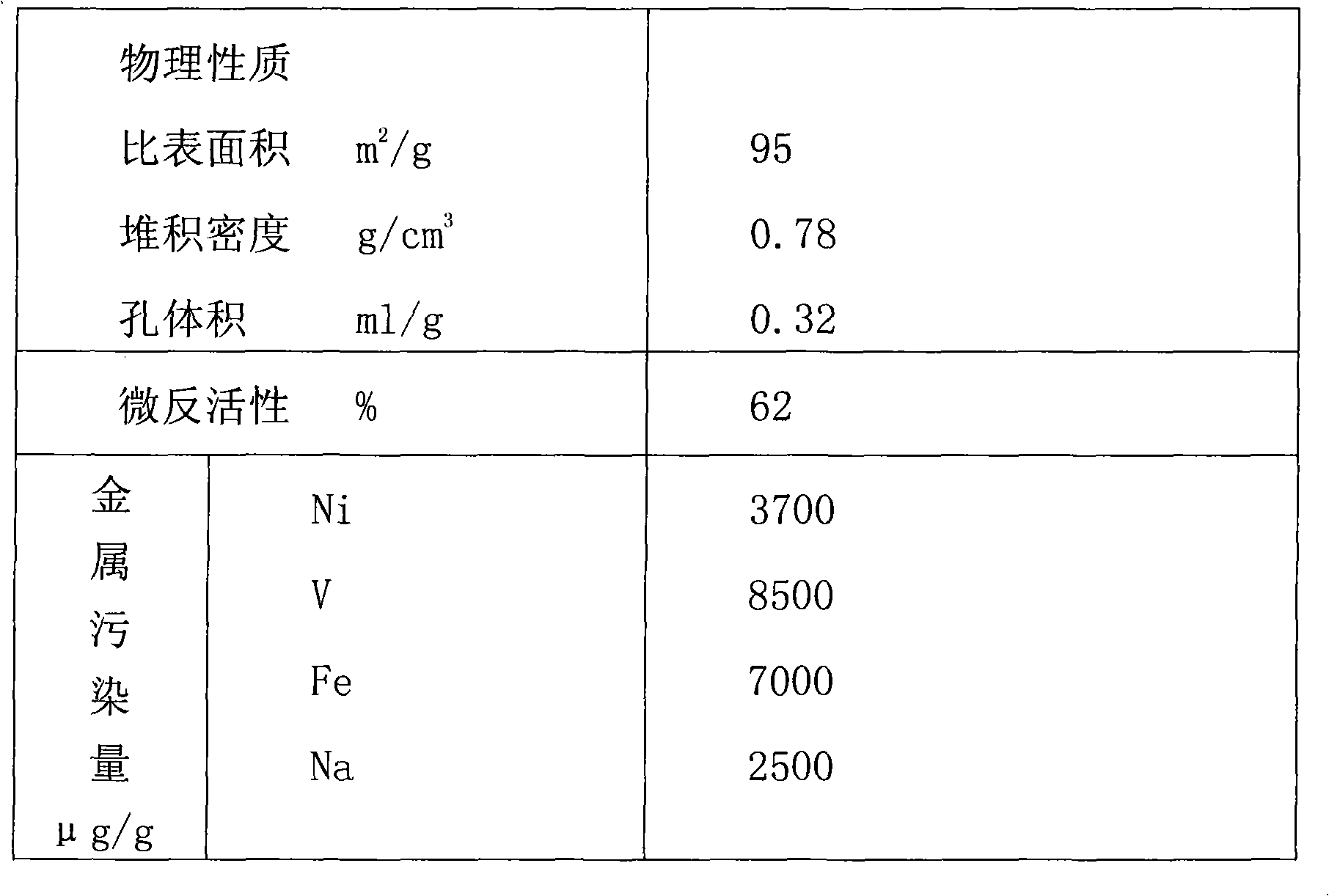

[0029] Example 1 A petrochemical group in Shandong Province has established a delayed coking unit with an annual processing capacity of 1 million tons and a double-riser catalytic cracking unit with an annual processing capacity of 600,000 tons. The raw material of the catalytic cracking unit of Comparative Example 1 was used as the feed of the delayed coking unit, and conventional delayed coking process conditions were adopted, and the material balance was 4% of coking gas, 21% of coke, and 75% of coking oil. The physical and chemical properties of coking oil are shown in Table 5. The oil produced by coking is used as the feed to the main riser of the dual riser catalytic cracking unit, and the obtained catalytic gasoline is used as the feed to the auxiliary riser, and cracked under the process conditions given in Table 3. The catalyst used was the Flex-Tec catalyst produced by Engelhard, and the physical and chemical properties of the catalyst balancer are shown in Table 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com