Ultrathin mobile phone and assembling process thereof

An ultra-thin, mobile phone technology, applied in the direction of telephone structure, electrical components, transmission systems, etc., can solve the problems affecting the display effect, water pattern, affecting the thickness of the mobile phone, etc., to increase the viewing range, powerful functions, color saturation and The effect of increased contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

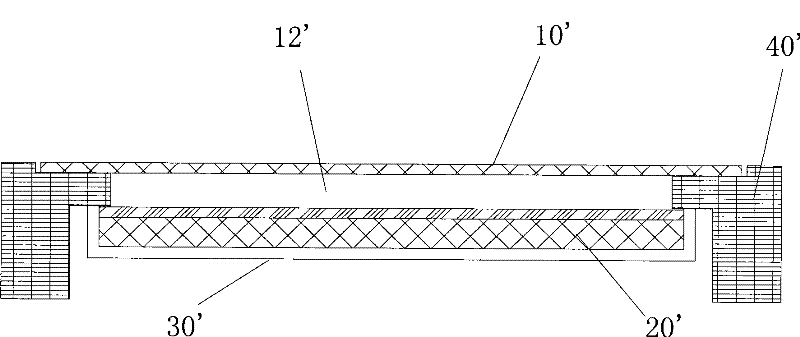

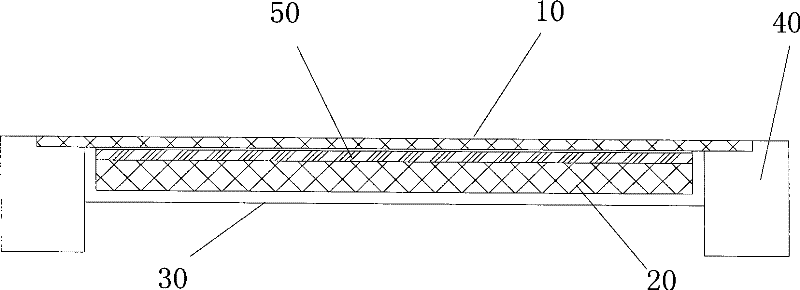

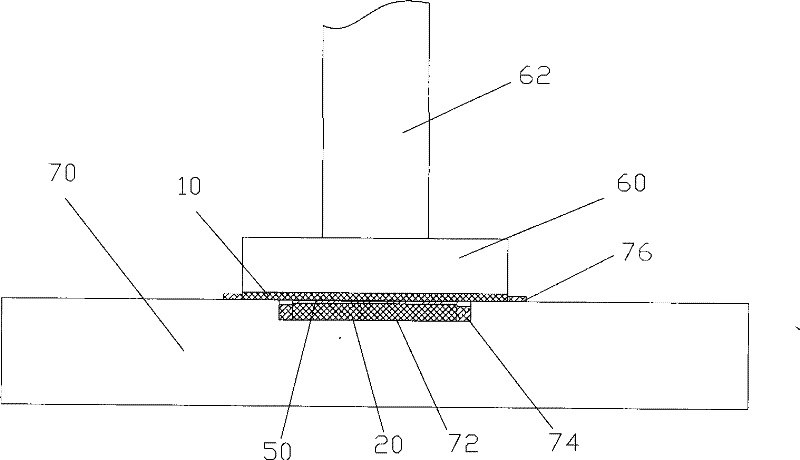

[0028] Please refer to figure 2 , the present invention relates to an ultra-thin mobile phone, comprising a casing 40, a liquid crystal display 20 disposed in the casing 40, and a protective lens 10 installed on the surface of the casing 40 and in front of the liquid crystal display 20. A transparent colloid 50 having the same refractive index as that of the protective lens is filled between the liquid crystal display screen 20 and the protective lens 10 .

[0029] The transparent colloid 50 is formed by curing glue through light. Specifically, a photocurable glue of a certain pattern is coated on the liquid crystal display screen 20 , or a photocurable glue of a certain pattern is coated on the protective lens 10 . After the two are pasted together, the glue is evenly diffused to at least the visual area of the liquid crystal display 20 . Then use the photocuring with the main value of a certain waveband (generally adopting the long-wave ultraviolet light with the main v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com