Diode electrical characteristics test system

A test system and diode technology, applied in the direction of single semiconductor device testing, etc., can solve the problems of affecting accuracy, large additional loss, and difficulty in characterization of product positioning, so as to save power consumption, large output range, and fast test speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

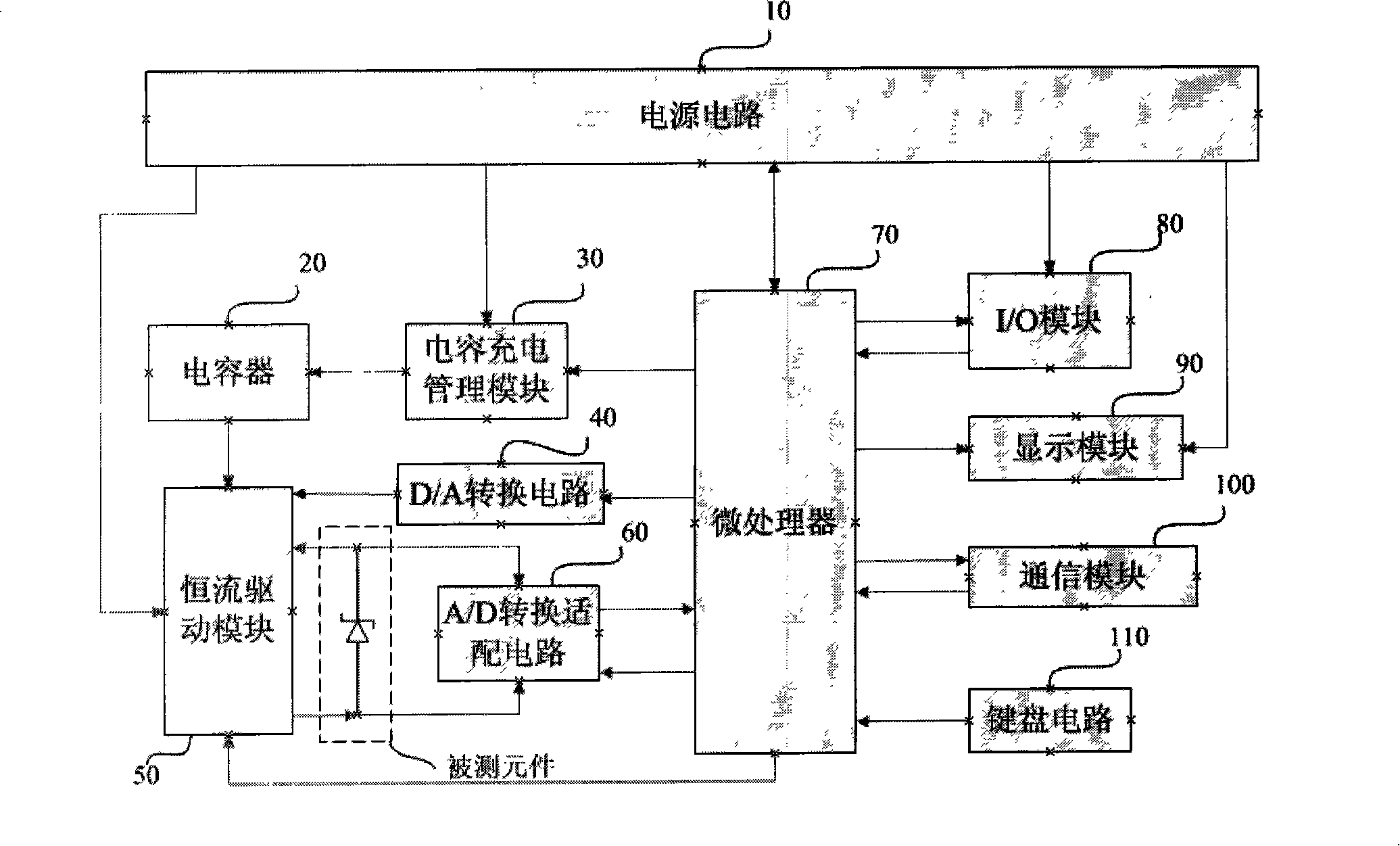

[0033] refer to figure 1 , a diode electrical characteristic test system, comprising:

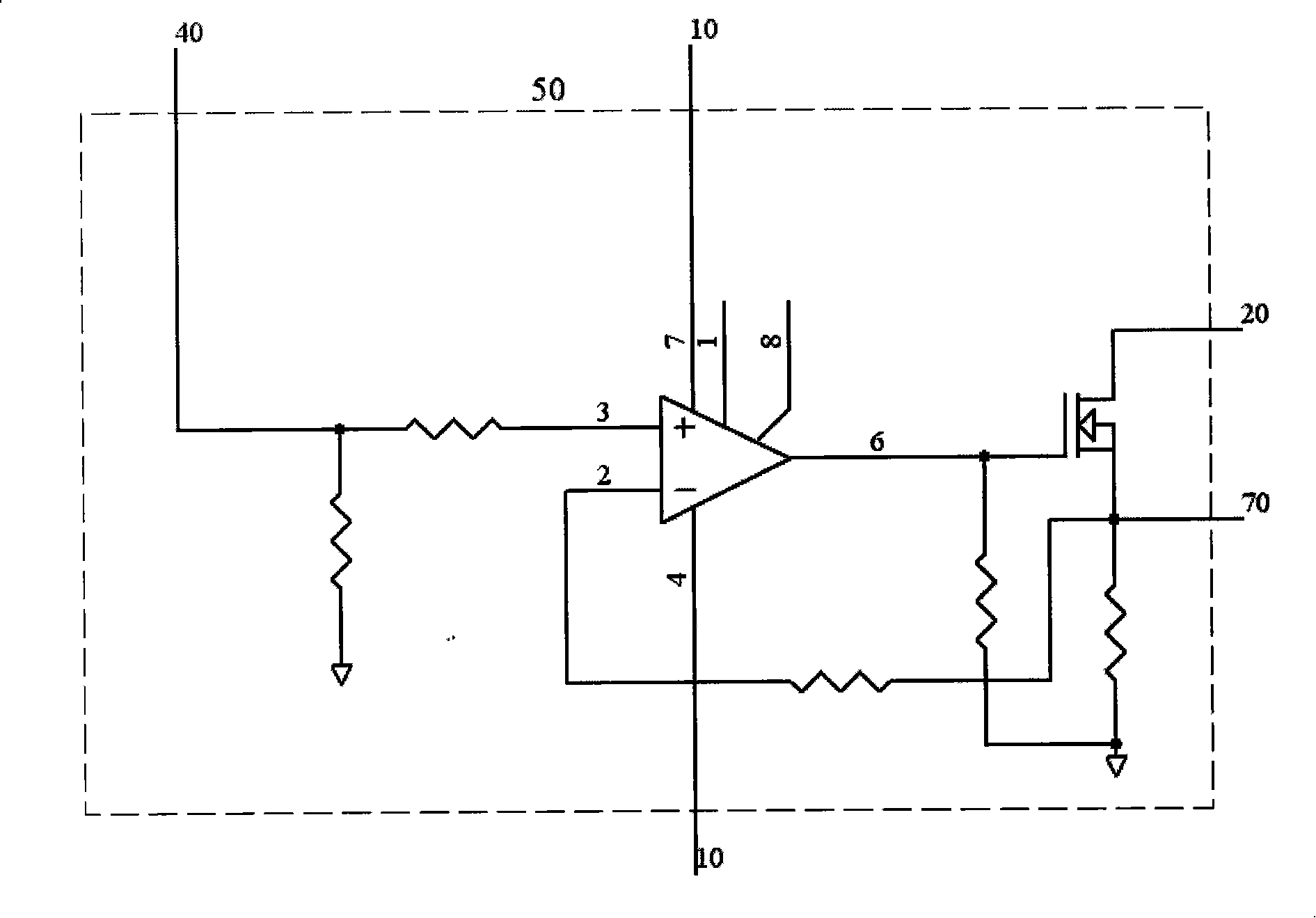

[0034] A constant current drive module 50, used to generate a stable current to the diode under test;

[0035] A D / A conversion circuit 40, connected to the constant current drive module, used to set the control analog quantity of the constant current drive module;

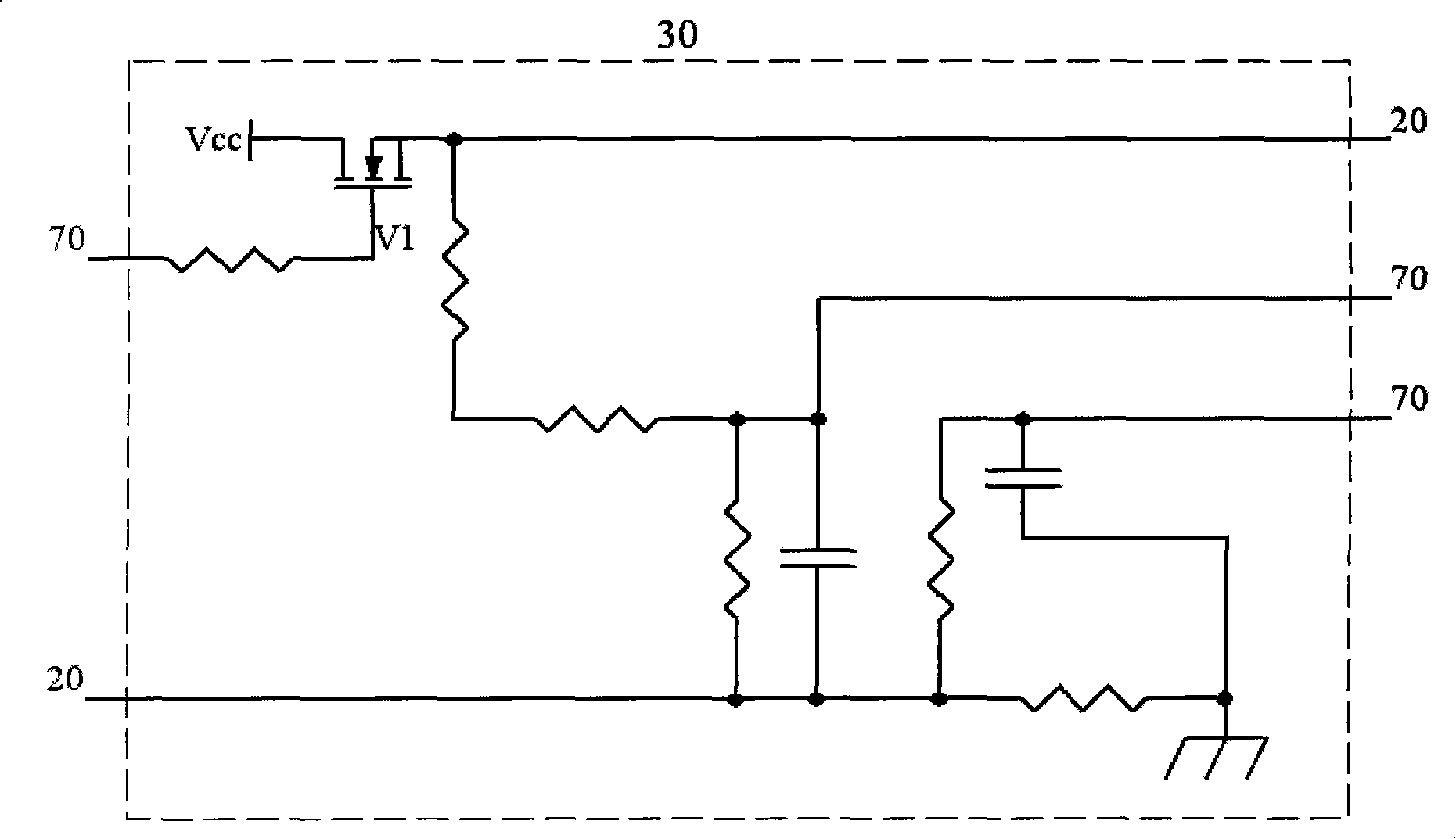

[0036] A capacitor 20, connected to the constant current drive module, used to provide the constant current drive module with an instantaneous high current power supply;

[0037] A capacitor charging management module 30, connected to the capacitor, used to manage the charging of the capacitor and detect the state of the capacitor;

[0038] An A / D conversion adaptation circuit 60, which is used to sample the voltage at both ends of the diode under test and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com