Method for preparing amphiprotic chitosan flocculant

A technology of chitosan and flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of cumbersome preparation methods, difficult promotion, and low practical operability, and achieves wide application range, low cost, good resistance The effect of salt properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

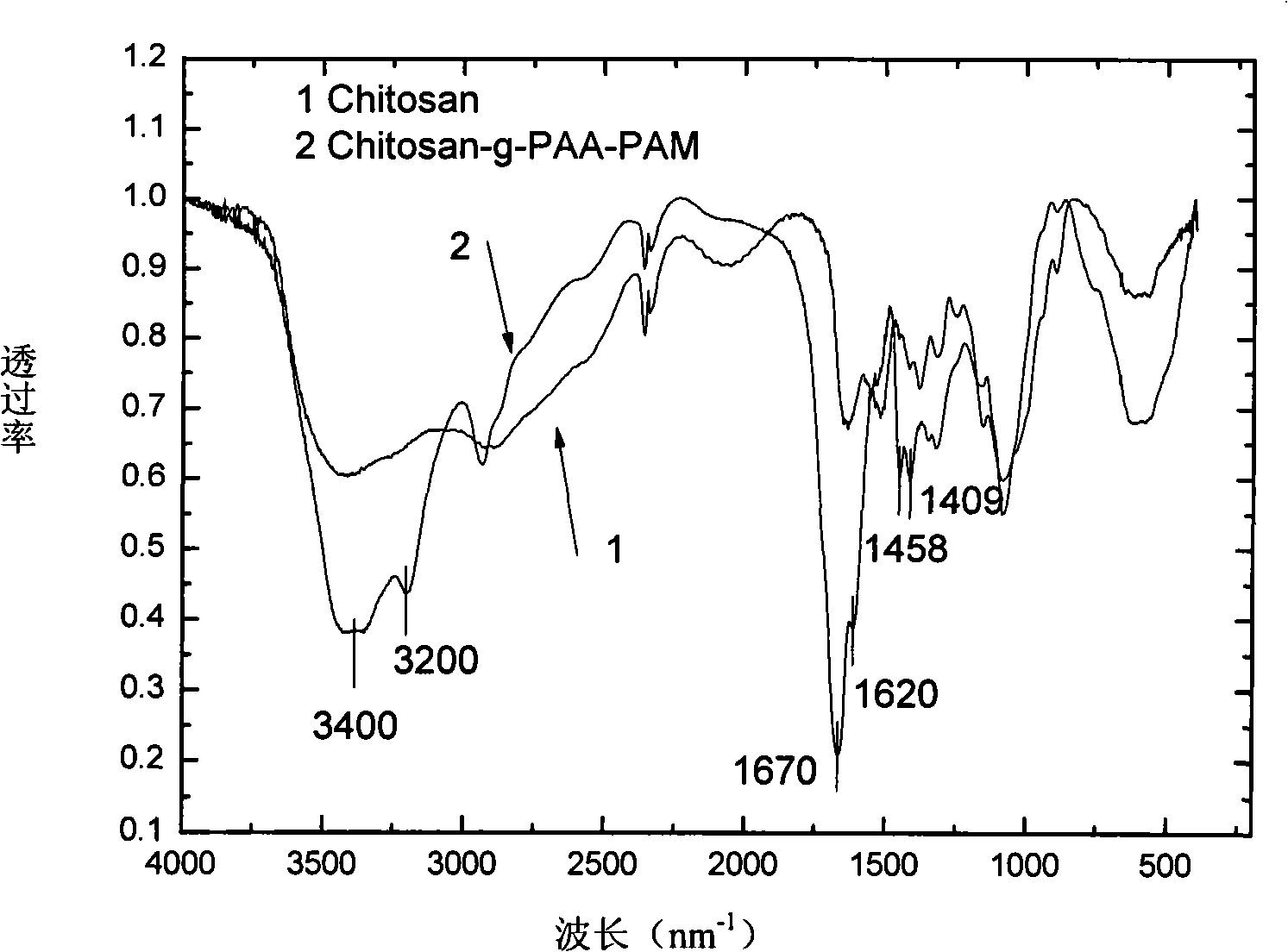

[0026] Dissolve chitosan in 0.5% acrylic acid aqueous solution, prepare the solution of 2% chitosan, after the solution is uniform, add cerium ammonium nitrate as initiator (addition amount is 3% of chitosan unit mole number) , then add another modifier acrylamide (mass ratio to chitosan: 5:1), and react at 45°C for 2 hours to obtain amphoteric chitosan grafted with polyacrylic acid and polyacrylamide. flocculant. Through titration analysis, the polyacrylic acid content is 10%, and the polyacrylamide content is 40% (by mass). Infrared spectrum of chitosan and amphoteric chitosan flocculant (chitosan grafted polyacrylamide-polyacrylic acid) see figure 1 ,from figure 1 See wavenumber 3400, 3200nm -1 O-H, N-H characteristic absorption peak; 1670, 1620nm -1 It is the characteristic absorption peak of amide carbonyl; 1409nm -1 It is the characteristic absorption peak with negative ion carbonyl, which proves that polyacrylamide and polyacrylic acid have been grafted onto the mo...

Embodiment 2

[0028] Dissolve chitosan in 1.0% acrylic acid aqueous solution, prepare the solution of 3% chitosan, after the solution is uniform, add cerium ammonium nitrate as initiator (addition amount is 2% of chitosan unit mole number) , then add another modifier acrylamide (mass ratio to chitosan: 5:1), and react at 45°C for 2 hours to obtain amphoteric chitosan grafted with polyacrylic acid and polyacrylamide. flocculant. After analysis, the polyacrylic acid content is 20%, the polyacrylamide content is 30% (mass), and its performance is similar to that of Example 1.

Embodiment 3

[0030] Dissolve chitosan in 0.5% acrylic acid aqueous solution, prepare the solution of 2% chitosan, after the solution is uniform, add cerium ammonium nitrate as initiator (addition amount is 3% of chitosan unit mole number) , then add another modifier acrylamide (mass ratio to chitosan: 8:1), and react for 2 hours at 45°C to obtain amphoteric chitosan grafted with polyacrylic acid and polyacrylamide. flocculant. After analysis, the polyacrylic acid content is 8%, the polyacrylamide content is 50% (by mass), and its performance is similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com