Folding and unfolding mechanism of back-unfolding stabilizing fin device

A technology of retractable mechanism and fin stabilizer, which is applied in the direction of using hydrofoils to act on the surrounding water surface to reduce the movement of ships, etc. It can solve the problems of negative influence of fin function and large starting resistance of mechanism oil cylinder, etc., so as to change labor-intensive and time-consuming operations, extend The effect of service life and improvement of load-carrying conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

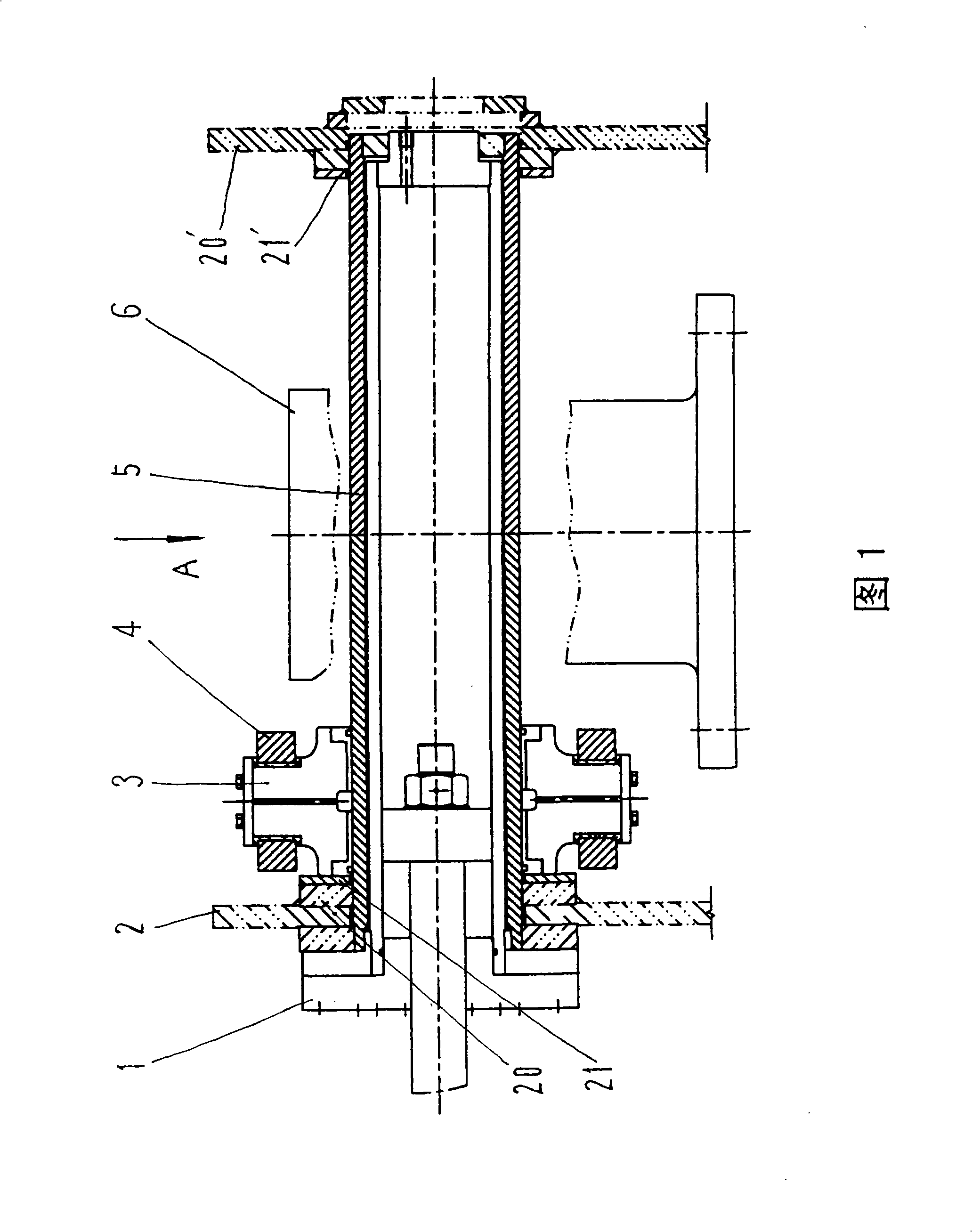

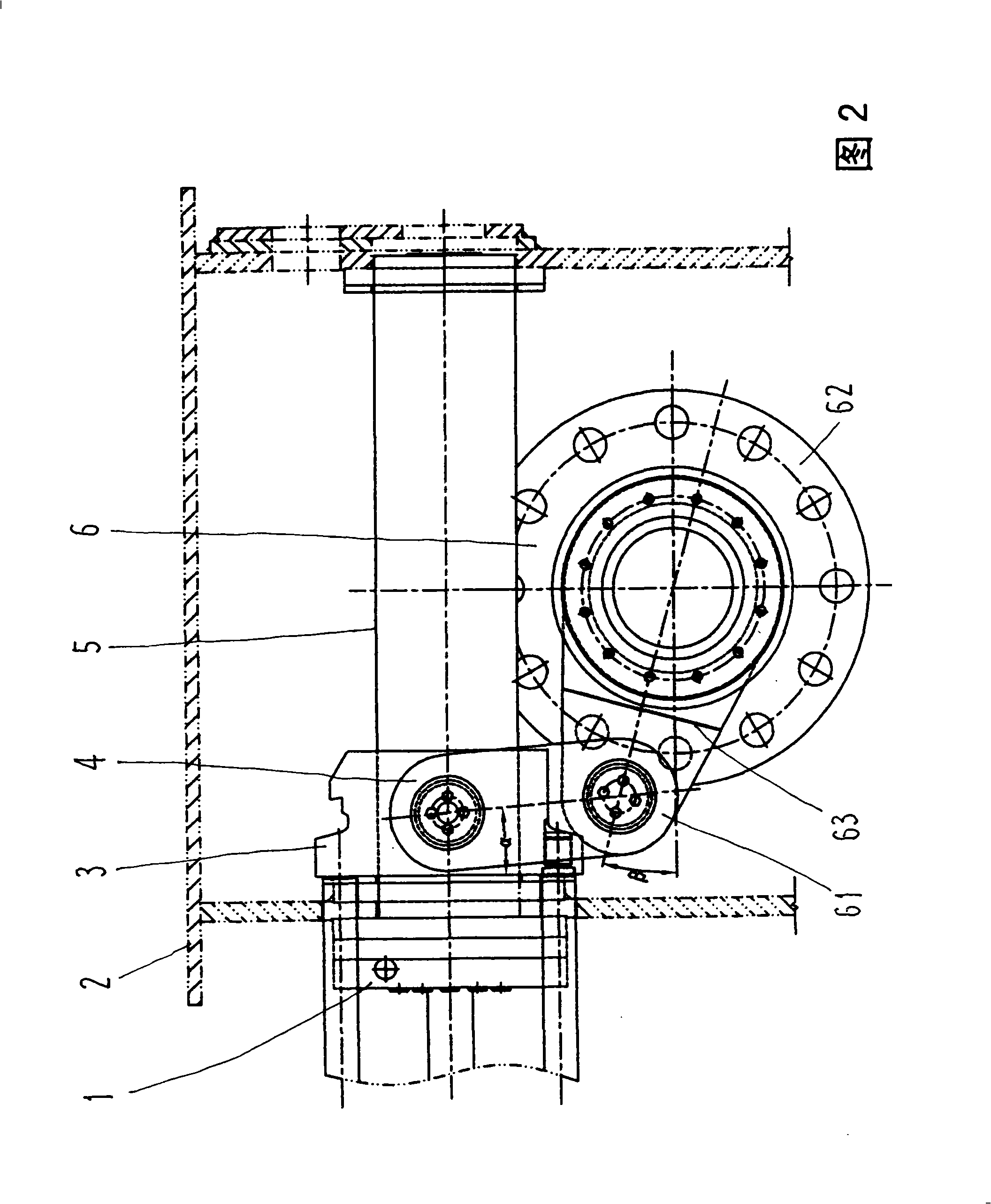

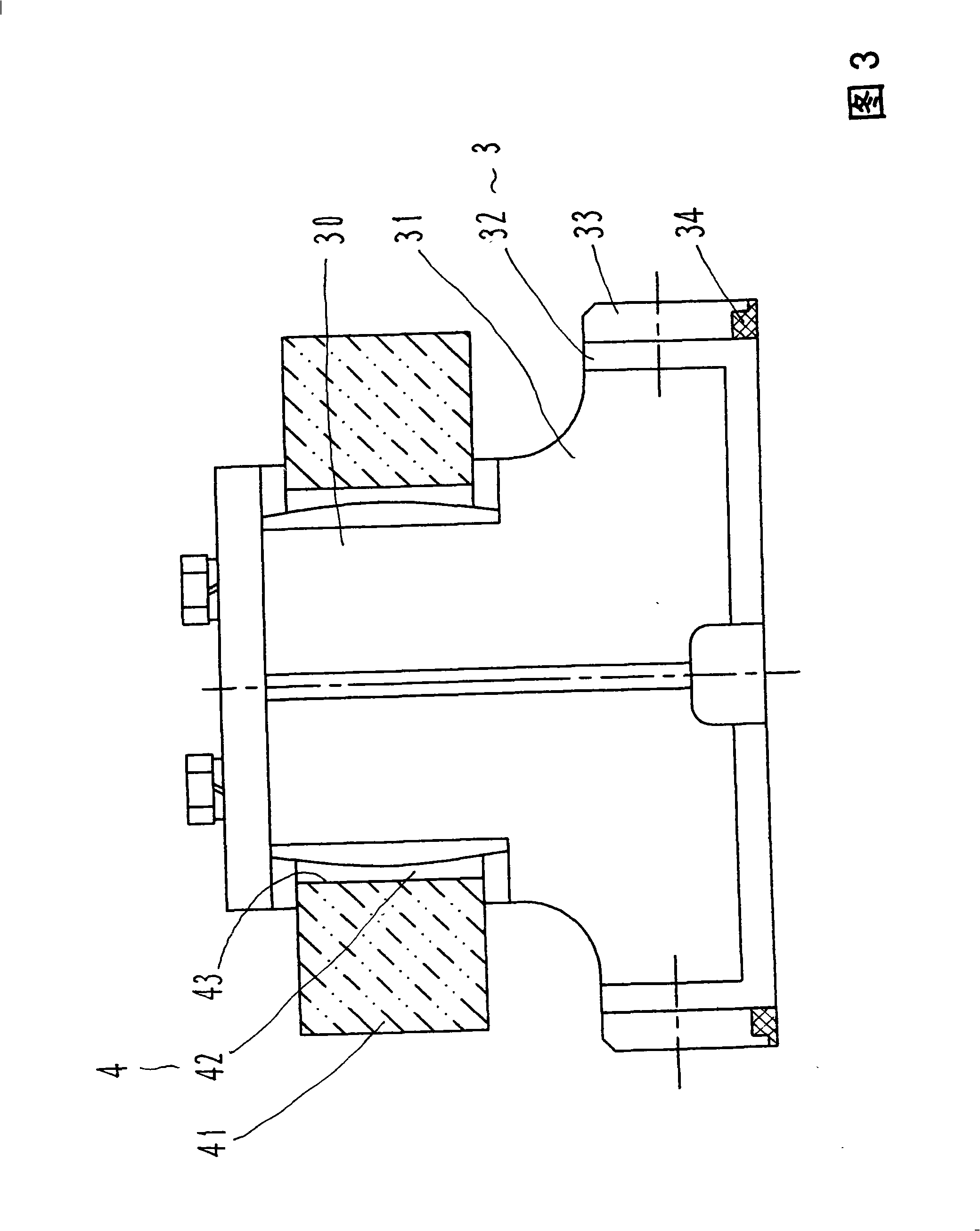

[0013] Referring to Figures 1 and 2, the retractable mechanism of the rear retractable fin stabilizer includes a retractable oil cylinder 1, a fin box 2, a sliding sleeve 3, a retractable connecting rod 4, a guide sleeve 5, a rotating body 6 and a locking mechanism.

[0014] The retractable oil cylinder 1 is installed on the front and rear vertical plates of the fin box 2 to drive the movement of the retractable mechanism. The piston rod of the retractable oil cylinder 1 is connected with the sliding sleeve 3 through two push-pull rods, and the retractable oil cylinder 1 is set on the guide sleeve. within 5.

[0015] The fin box 2 is the supporting member of the retractable mechanism. The box body of the fin box 2 and the front and rear vertical plates 20, 20 ′ are welded together with the hull plate to form a closed structure. The front and rear vertical plates 20, 20 Between ', the fixed guide sleeve 5 is stretched, and the insides of the front and rear vertical plates 20, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com