Filtration medium for removing water color, foreign flavor and colloid substances and its preparation method

A filter medium and water removal technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of not being able to remove the color and odor of water well, and achieve the purpose of purifying drinking water, Improve water quality and remove efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

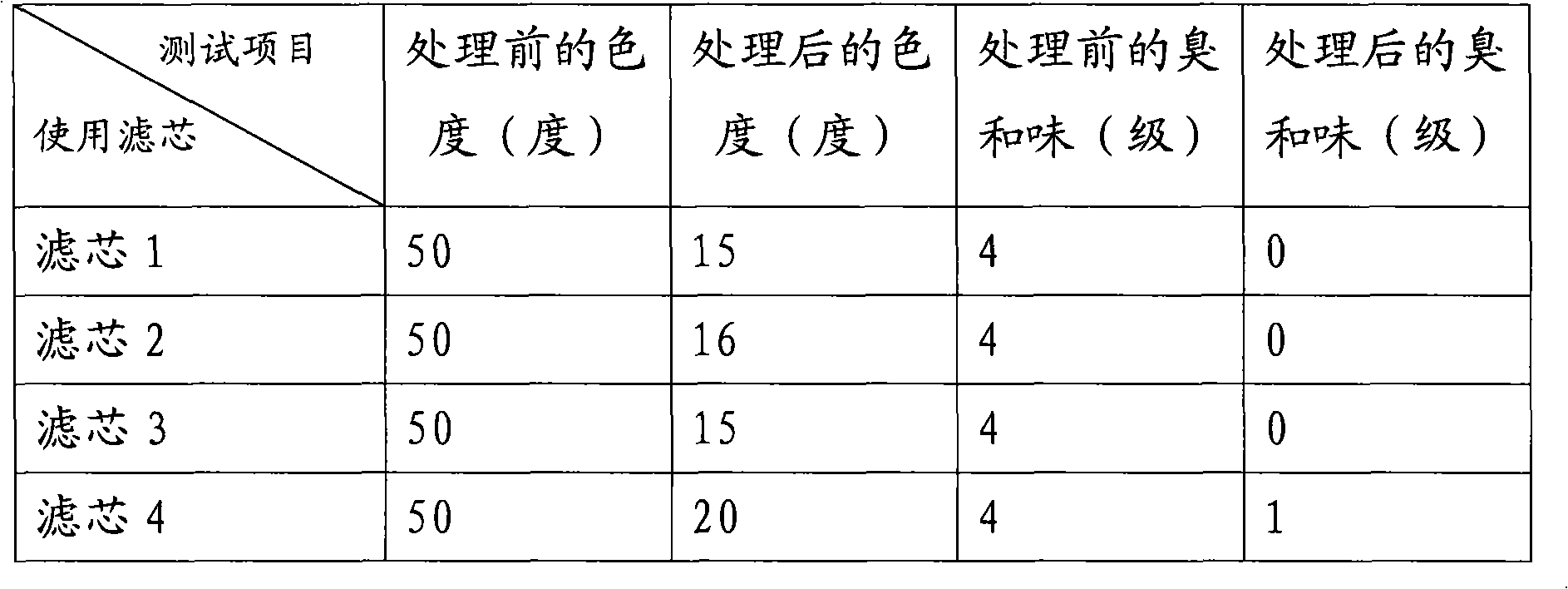

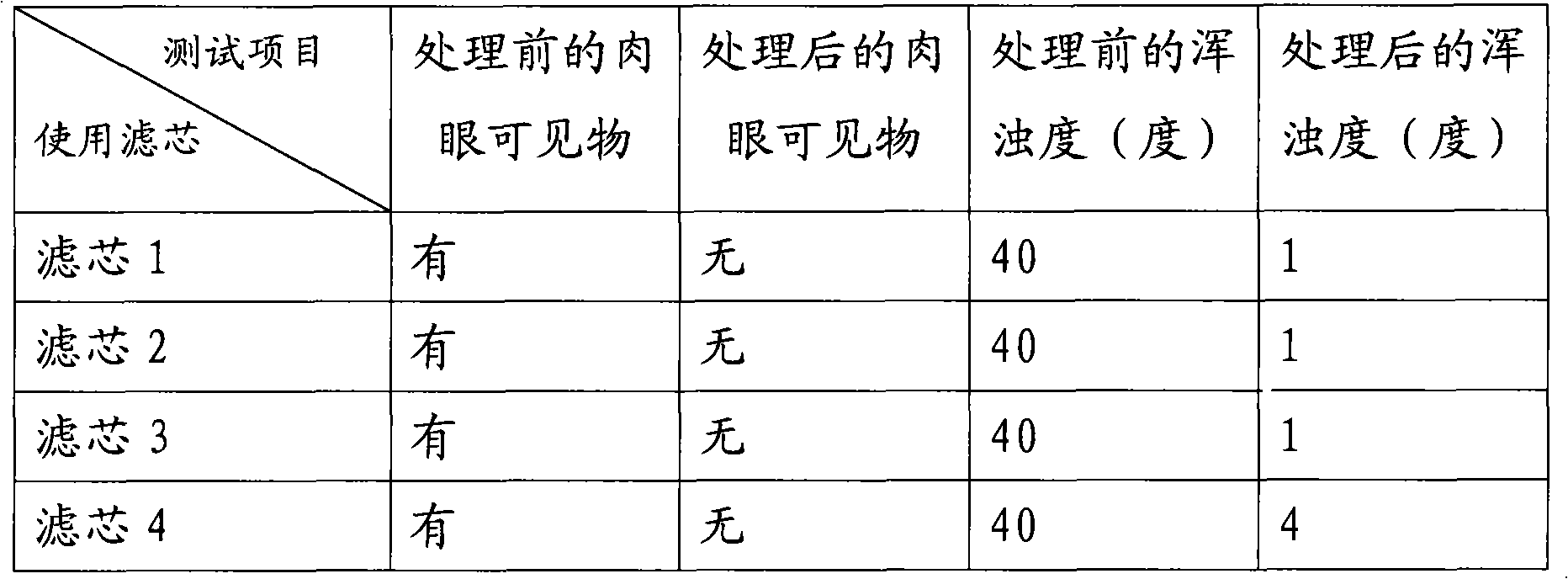

Examples

Embodiment 1

[0041] Take by weighing 100 grams of medical activated carbon with a particle size of 38 to 250 microns, 190 grams of ultra-high molecular weight polyethylene powder with a molecular weight of 3.5 million (Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 20 grams of rod stone powder, 10 grams of 44-124 micron zeolite powder. Put the above four powders into a mechanical stirrer and mix them evenly, then fill them into a tubular mold, press under a hydraulic pressure of 0.6MPa, sinter at 250°C for 150 minutes, cool to 60°C and demould, It can be made into a tubular filter element with many micropores.

Embodiment 2

[0043] Weigh 150 grams of medical activated carbon with a particle size of 178 to 710 microns, 200 grams of ultra-high molecular weight polyethylene powder (Beijing Dongfang Petrochemical Co., Ltd. Auxiliary Plant No. 2, M-III type) with a molecular weight of 3.5 million, and attapulgite powder 40 grams, 25g of 30-420 micron zeolite powder. The above four powders were put into a mechanical stirrer and stirred evenly, and the rest of the manufacturing steps were the same as in Example 1.

Embodiment 3

[0045] Take by weighing 200 grams of medical activated carbon with a particle size of 26 to 250 microns, 250 grams of ultra-high molecular weight polyethylene with a molecular weight of 2.5 million (Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, M-II type), acidified attapulgite 30 grams of stone powder, 30 grams of 38-89 micron zeolite powder. The above four powders were put into a mechanical stirrer and stirred evenly, and the rest of the manufacturing steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com