Sensitive large signal output minitype pressure sensor

A pressure sensor, large-signal technology, applied in the sensor field, can solve the problems of not highlighting the superiority of the CAP-FET structure, the MOSFET gate length is too large, the output result error, etc., to overcome the short channel effect, improve the analog properties, The effect of large magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

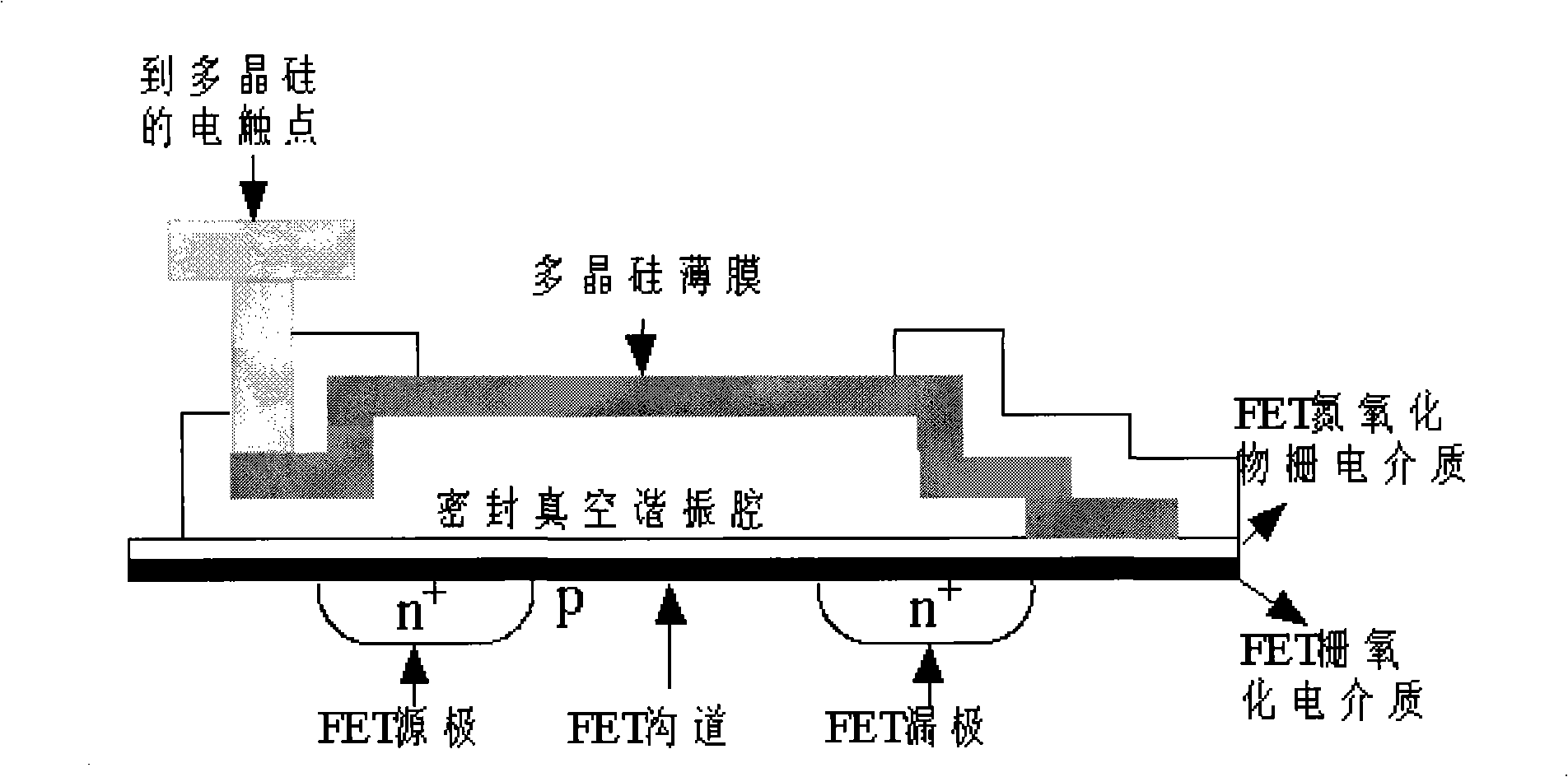

[0030] The embodiment of the present invention provides a sensitive large-signal output miniature pressure sensor. Specifically, the conductive floating layer of the capacitive part of the sensor is adjusted and extended to the gate insulating layer of the MOSFET device to form the floating gate of the MOSFET device, so that the capacitive part of the sensor and the The lower MOSFET device is separated so that the structure size of the sensor capacitive part has no influence on the MOSFET device.

[0031] For better describing the present invention, now in conjunction with accompanying drawing, the specific embodiment of the present invention is described:

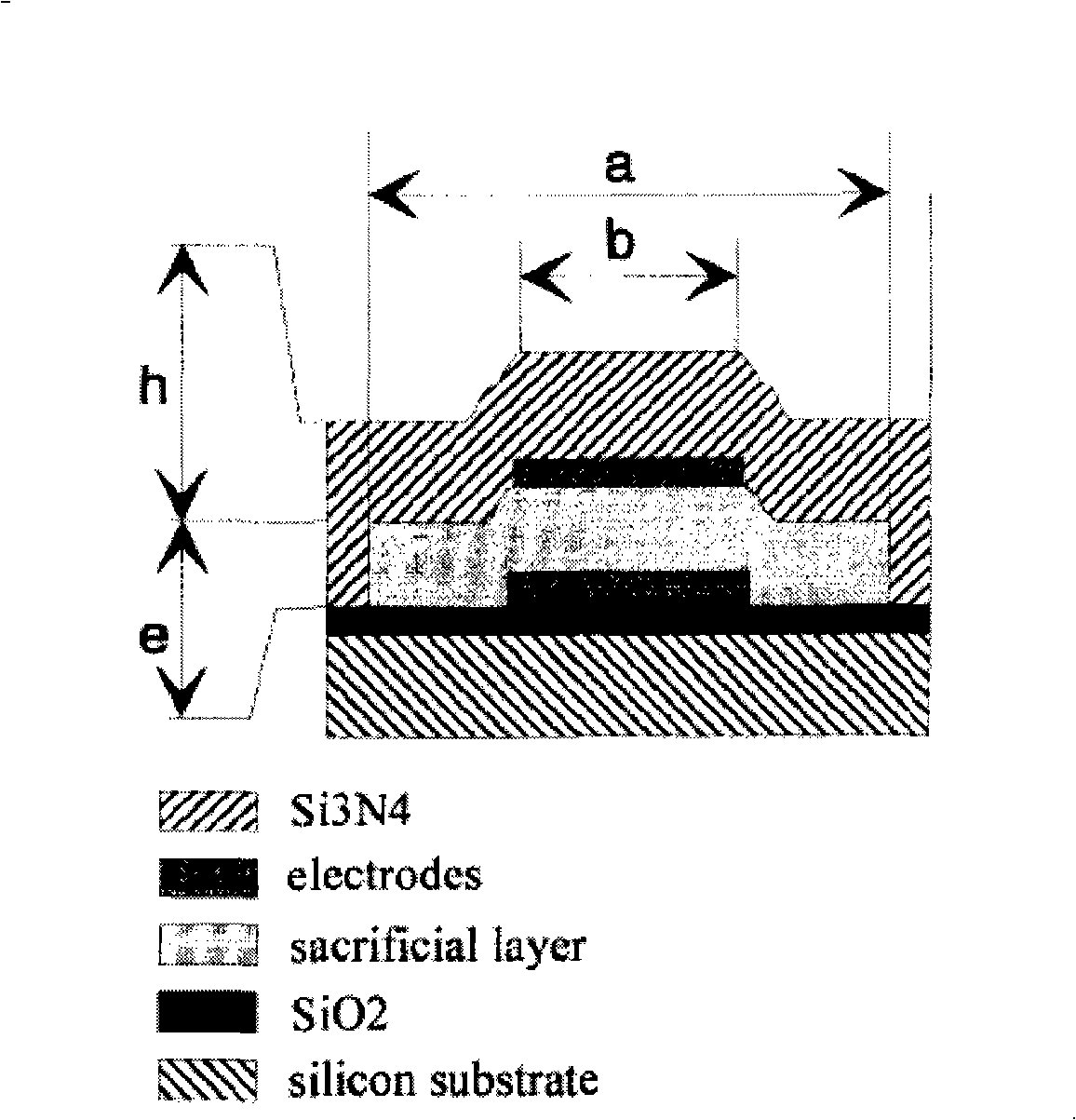

[0032] As shown in Fig. 4 (a) and (b), it is a top view and a cross-sectional view of the sensor structure in the embodiment of the present invention. In the figure, the sensor of the present invention includes a sensor capacitor part and a MOSFET device, wherein the sensor capacitor part includes a sensor polysilicon film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com