Integrated type hydraulic headstock gear total closed oil tank

A hydraulic hoist, fully enclosed technology, applied in the direction of the fuel supply tank device, mechanical equipment, fluid pressure actuating device, etc., can solve the problem that the fuel tank cannot be installed in any direction, and achieve safe and reliable work and high oil cleanliness. , the effect of large oil storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

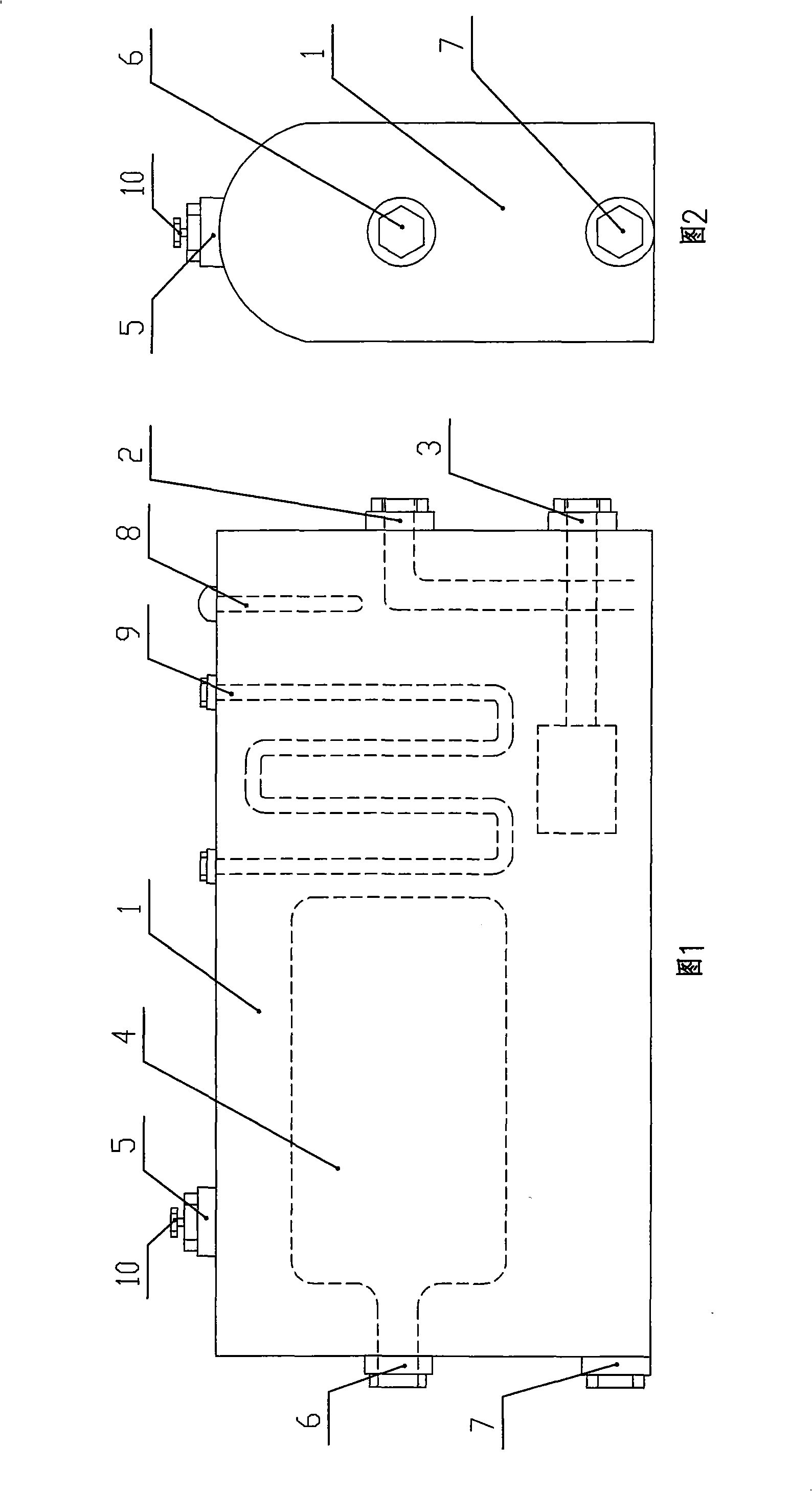

[0018] The best embodiment of the fully enclosed oil tank of the integrated hydraulic hoist of the present invention as shown in Figure 1 has a fully enclosed oil storage box 1, and a soft air bag 4 is arranged in the box body 1, and the material of the air bag 4 is D Clear rubber N230, tank 1 is equipped with oil suction port joint 2, oil return port joint 3, oil filling port joint 5, oil discharge port joint 7 and air bag joint 6, oil suction port joint 2, oil return port joint 3, oil filling port joint 5 Sealing rings are added to the joint 7 of the oil discharge port to ensure that there is no oil leakage when the fully enclosed fuel tank of the integrated hydraulic hoist is installed in any direction. The tank body 1 is also equipped with a fuel tank heater 8 and a fuel tank cooler 9, and a fuel tank joint 5 An air release valve 10 is arranged on the top, and the fuel filler joint 5 is blocked with a plug with an air outlet. The air release valve 10 is installed on the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com