Method for recovering cement-based material crack by means of microorganism, culture fluid and repair nutrient fluid

A cement-based material and microbial restoration technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems that affect the normal use of materials, induce macroscopic cracks, limit the application range, etc., and achieve volume stability and Excellent durability, low cost, and outstanding environmental friendliness

Active Publication Date: 2010-11-24

SOUTHEAST UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if it cannot be repaired in time, it will not only affect the normal use of the material, but may also induce macroscopic cracks and brittle fracture.

At present, the crack repair materials commonly used in engineering mainly include cement-based permeable crystalline materials, polymer mortar, polymer grouting materials, etc. Although these materials have played an important role in the repair of many structural crack defects, they are still inevitable. However, there are some defects, such as the durability of materials, environmental friendliness, etc., which also greatly limit their application range.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 1-1

Embodiment 1-2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

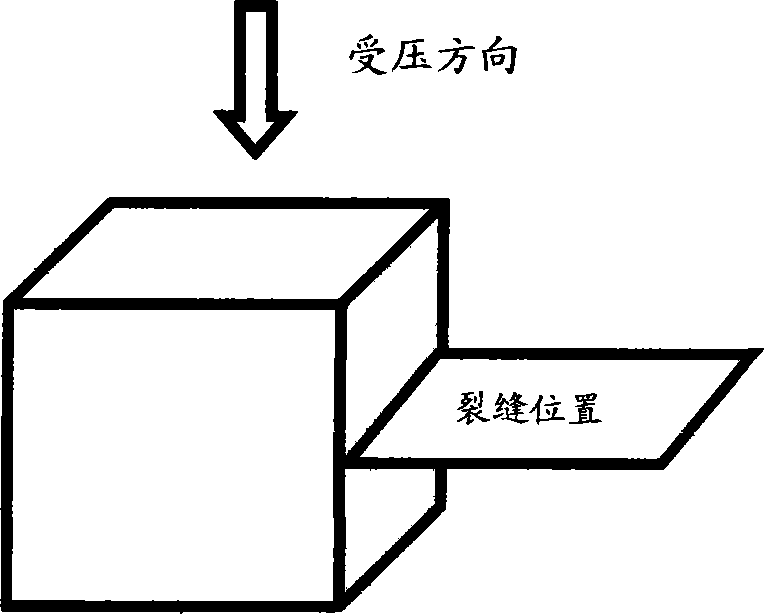

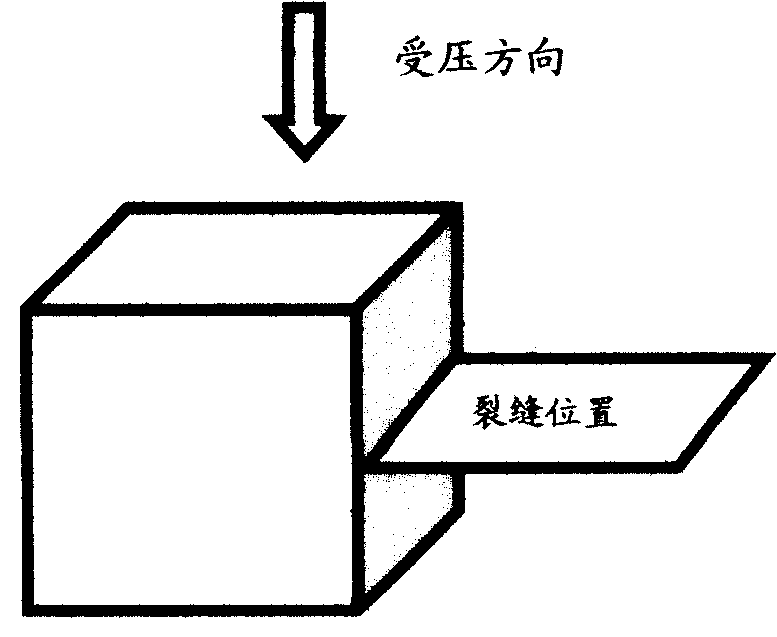

The invention discloses a method for repairing cement-based material cracks, as well as a culture solution and a repair nutrient solution. The method for repairing cement-based material cracks by through microorganisms comprises the following steps that: a Bacillus pasteurii strain is inoculate onto a culture medium provided with a urea-containing substrate; shake cultivation is carried out at a temperature of between 25 and 37 DEG C, and then a culture bacteria solution is taken out and centrifuged and has supernatant fluid removed; strain cells are collected through the culture solution; the concentration of the strain cells is controlled in a range of between 2x10<9> and 1x10<11> cell / ml; standard sand, urea and Ca(NO3)2.4H2O mixture are added to each milliliter of strain cell solutionobtained through collection, mixed, stirred into slurry and injected into cement stone cracks; the frequency of the repair nutrient solution injection is not less than two times; finally, maintenanceis carried out. In the culture solution, each liter of culture solution contains 4 to 6 g of peptone, 2 to 4 g of beef extract and 20 to 60 g of urea. The method fully utilizes microbial resources innature; CO3<2-> decomposed out through microbial enzyme can chelate Ca<2+> in a substrate so as to be mineralized and deposit calcium carbonate, and is close in the combination with the substrate andgood in stability.

Description

Method for repairing cracks in cement-based materials by using microorganisms, culture solution and repair nutrient solution technical field The invention relates to a method for repairing cracks in cement-based materials, a culture solution and a repairing nutrient solution, in particular to a method for repairing cracks in cement-based materials by using microorganisms to deposit calcium carbonate, as well as a culture solution and a repairing nutrient solution. Background technique Cement-based materials are currently the most widely used building materials, and their biggest disadvantage is that they are prone to micro-cracks and local damage under the influence of the surrounding environment during the material preparation process and service period. Cracks in concrete are inevitable, and their microscopic cracks are determined by their own physical and mechanical properties. However, if it cannot be repaired in time, it will not only affect the normal use of the mate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12N1/20C12P3/00E04G23/02C12R1/07

Inventor 钱春香王瑞兴

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com