Preparation of color ceramic hollow micro-bead pigment-filler

A technology of ceramic hollow micro-beads and hollow micro-beads, which is applied in filling slurry, fibrous filler, inorganic pigment treatment, etc., can solve the problems of power consumption, long production cycle, low efficiency, etc. Calcination cycle, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] 1. Preparation method of colored ceramic hollow microbead pigments and fillers

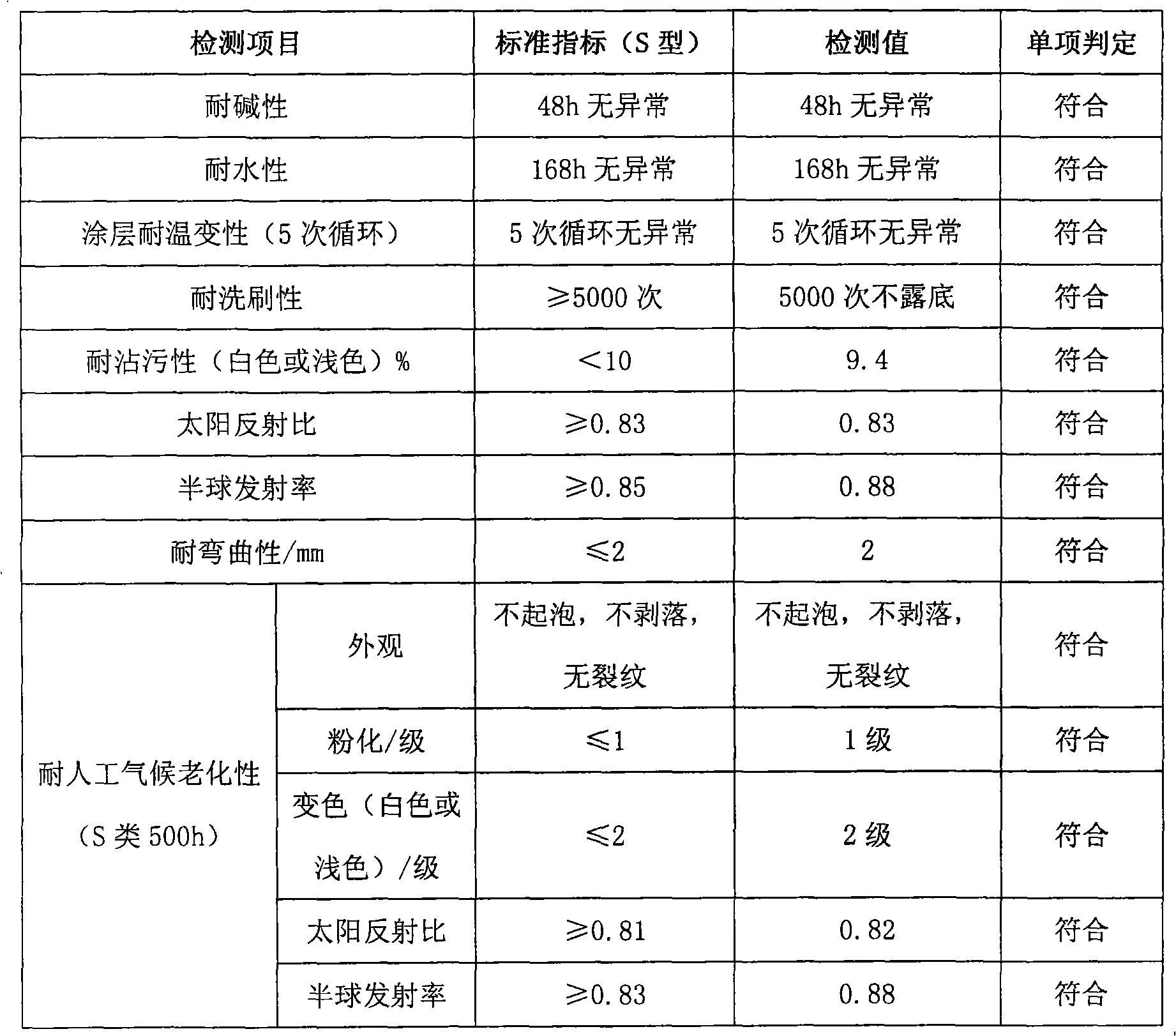

[0037] 1.1 The raw material components and preparation process parameters of color ceramic hollow microsphere pigments and fillers are shown in Table 3

[0038] 2. Preparation of colored heat reflective thermal insulation coating

[0039] 2.1 Preparation of solvent-based (S-type) colored heat-reflective heat-insulating coating, wherein the raw materials are all parts by weight

[0040] Component A: 68 parts of solvent-based resin

[0041] 20 copies of colored ceramic hollow microbead pigments and fillers

[0042] Polyethylene wax 0.5 parts

[0043] Polydimethylsiloxane 0.6 parts

[0044] Phosphate 1 part

[0045] Xylene 2.47 parts

[0046] Butyl acetate 6.43 parts

[0047] Ethylene glycol monoethyl ether acetate 1 part

[0048] Component B: Derivatives of hexamethylene diisocyanate

[0049] Group A: Group B = 13:1

[0050] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com