Device for removing SO2 pollutant in flue gas and method thereof

A pollutant and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficult emission control goals, high operation and maintenance costs, and economic inefficiency, and achieve enhanced gas-liquid mass transfer. , Sufficient effective space, good droplet dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

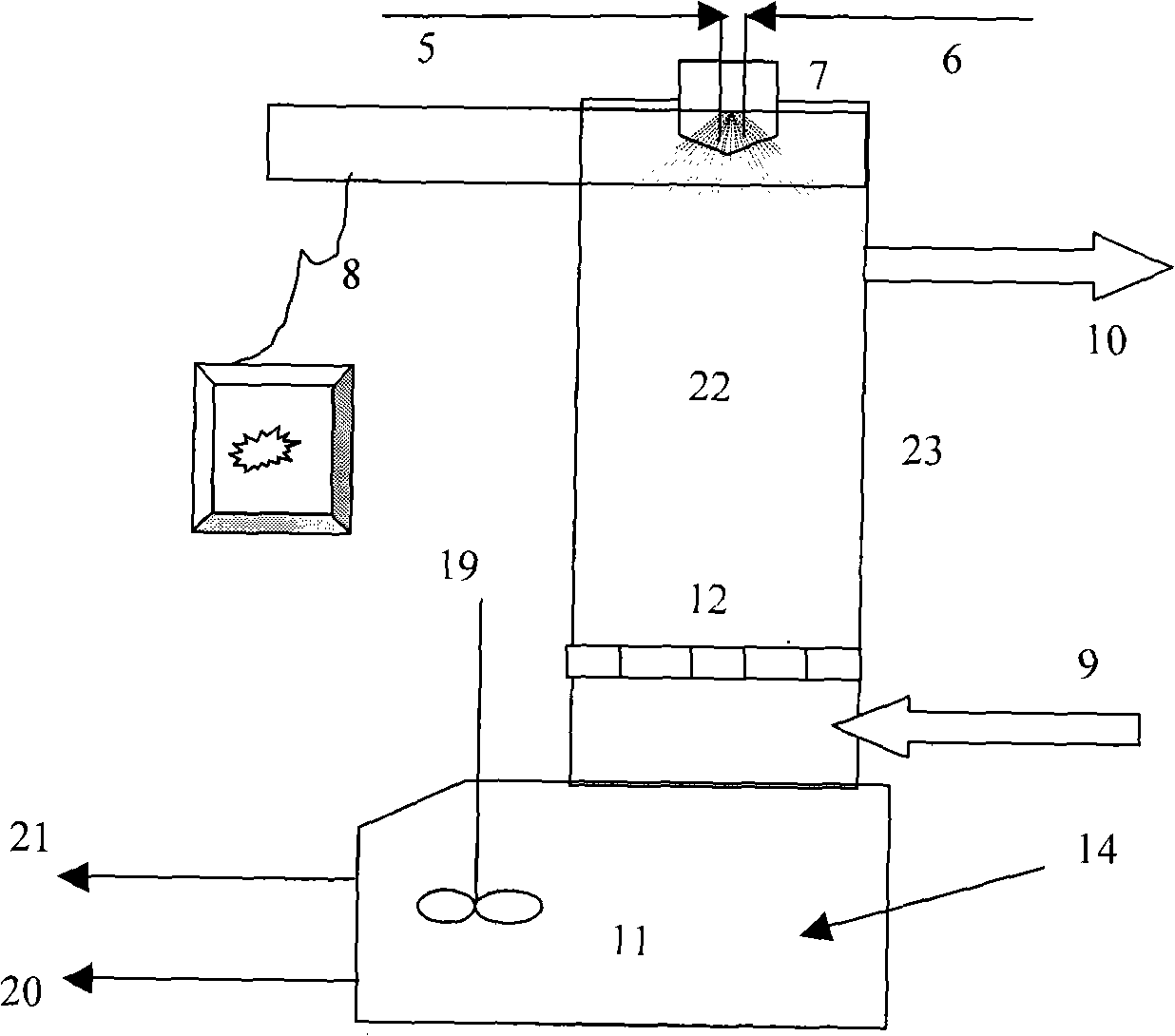

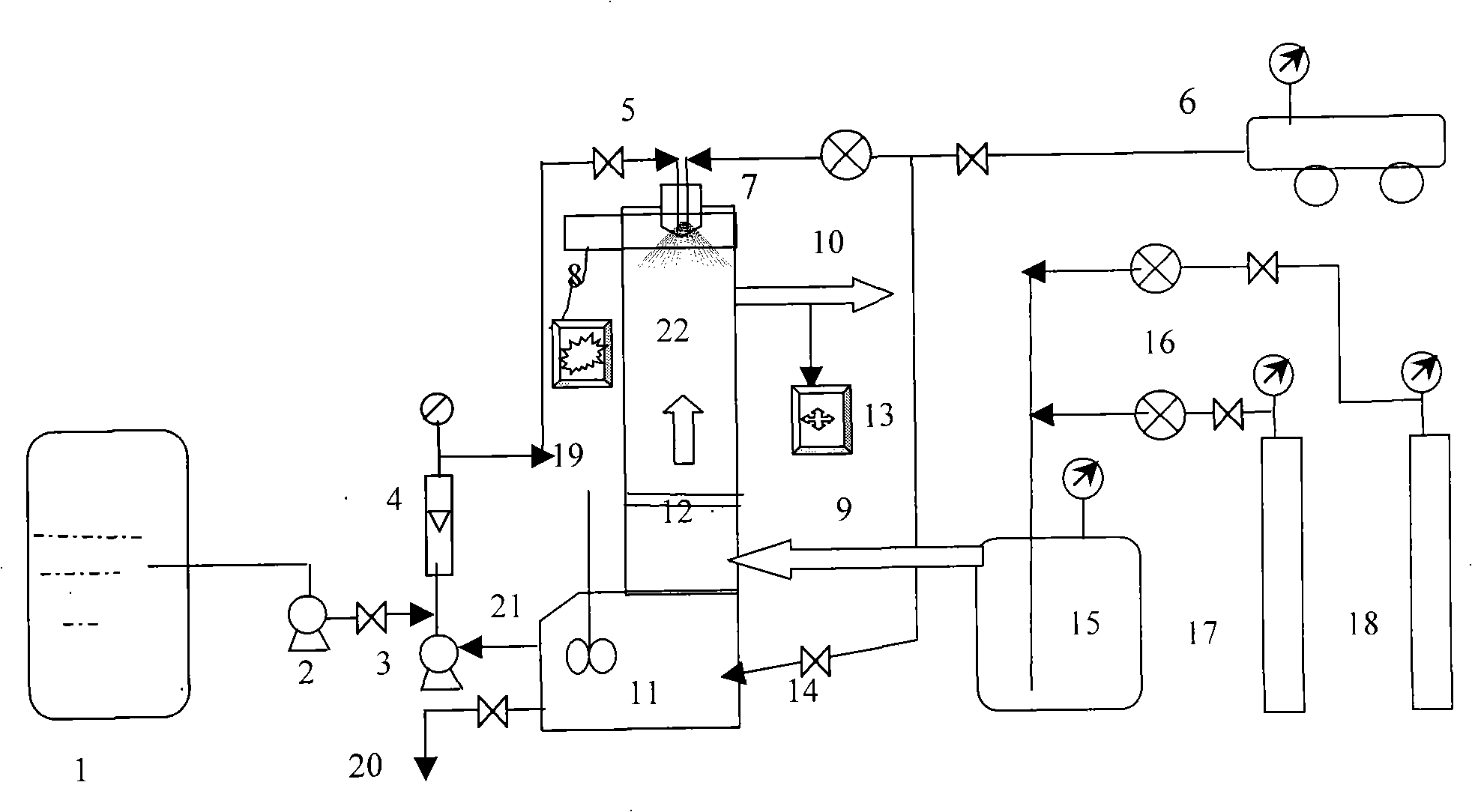

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 selects the flue gas flow rate as 5l / min, the limestone slurry flow rate as 50ml / min, the limestone slurry weight percentage concentration as 17%, and the imported SO 2 The concentration is 1500mg / m 3 , do not use electrostatic spray to set the applied voltage to 0kV, according to SO 2 The desulfurization efficiency calculated from the import and export concentration is 80%.

Embodiment 2

[0026] Embodiment 2 selects the flue gas flow rate as 5l / min, the limestone slurry flow rate as 50ml / min, the limestone slurry weight percentage concentration as 20%, and the imported SO 2 The concentration is 1500mg / m 3 , set the applied voltage to 10kV, according to SO 2 The desulfurization efficiency calculated from the import and export concentration is 86%.

Embodiment 3

[0028] Embodiment 3 selects the flue gas flow rate as 5l / min, the limestone slurry flow rate as 50ml / min, the limestone slurry weight percentage concentration as 15%, and the imported SO 2 The concentration is 1500mg / m 3 , set the applied voltage to 15kV, according to SO 2 The desulfurization efficiency calculated from the import and export concentration is 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com