Method for producing milk scenting agent flavor intensifier using sulfur-containing amino acid and sugar as raw material

A sulfur amino acid, amino acid technology, applied in the direction of milk preparations, food preparation, dairy products, etc., can solve the problems of unsatisfactory effect, lack, lack of fidelity, etc., to prolong the fragrance retention ability, improve the fullness and roundness, Taste the elegant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

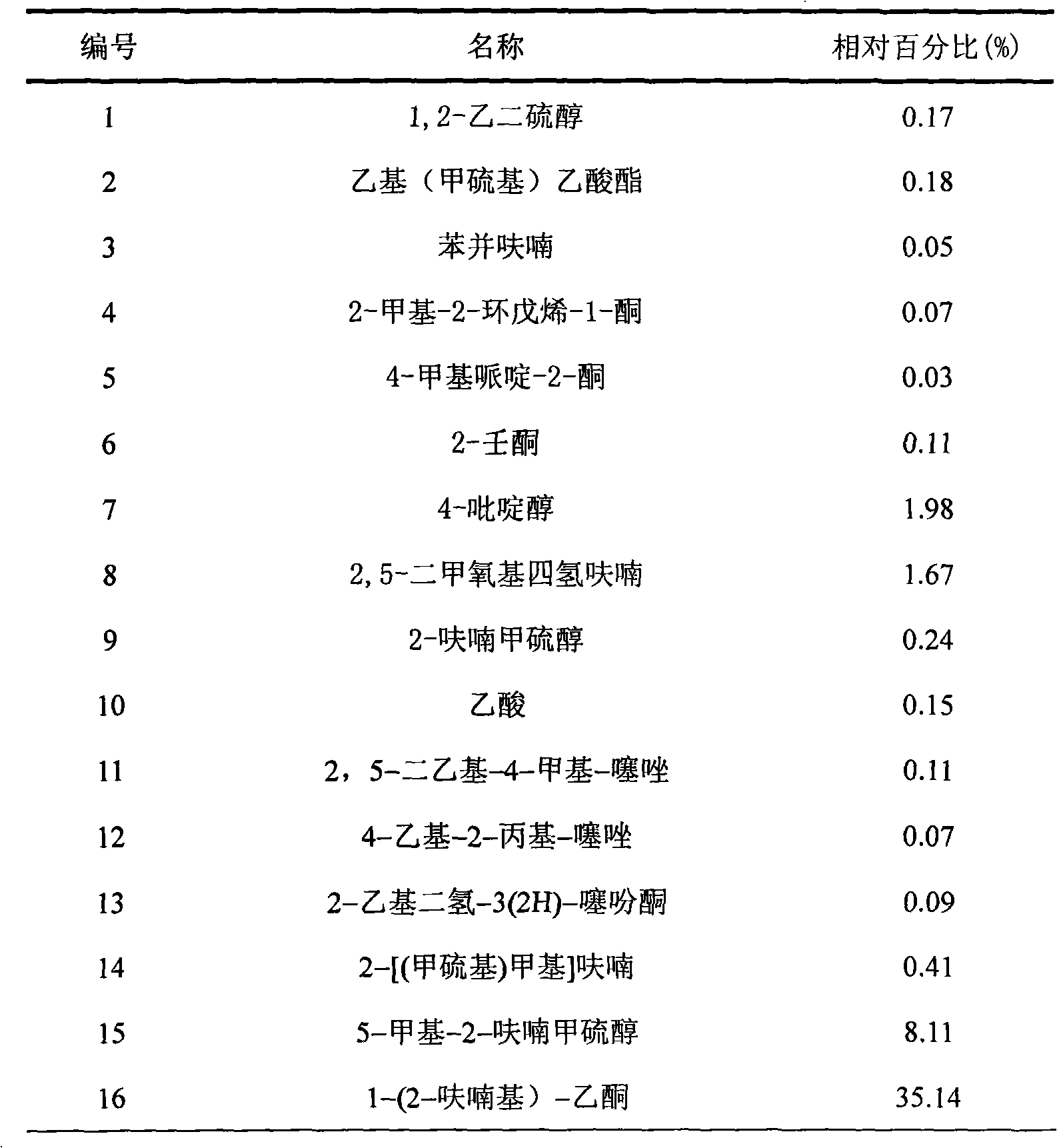

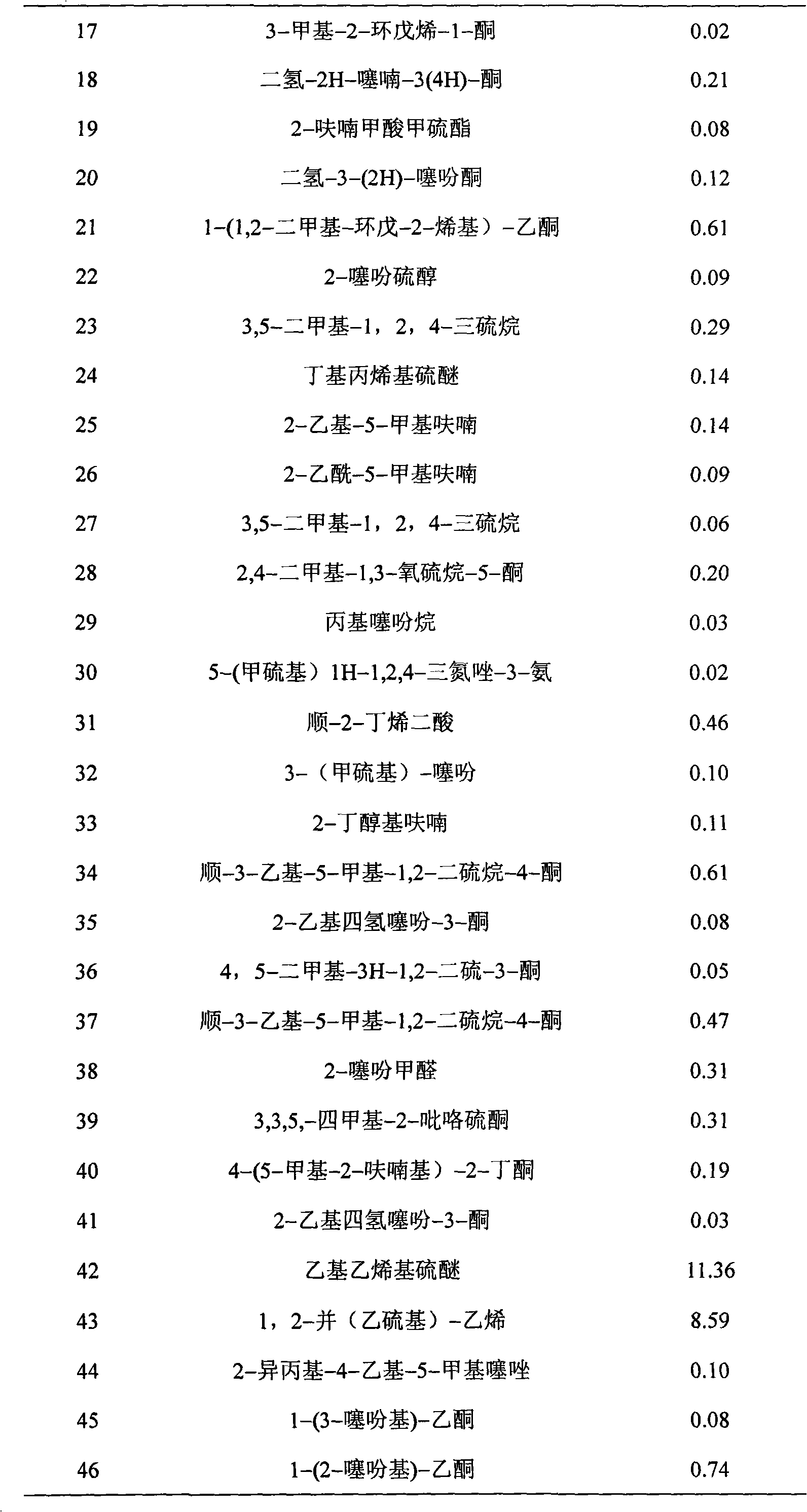

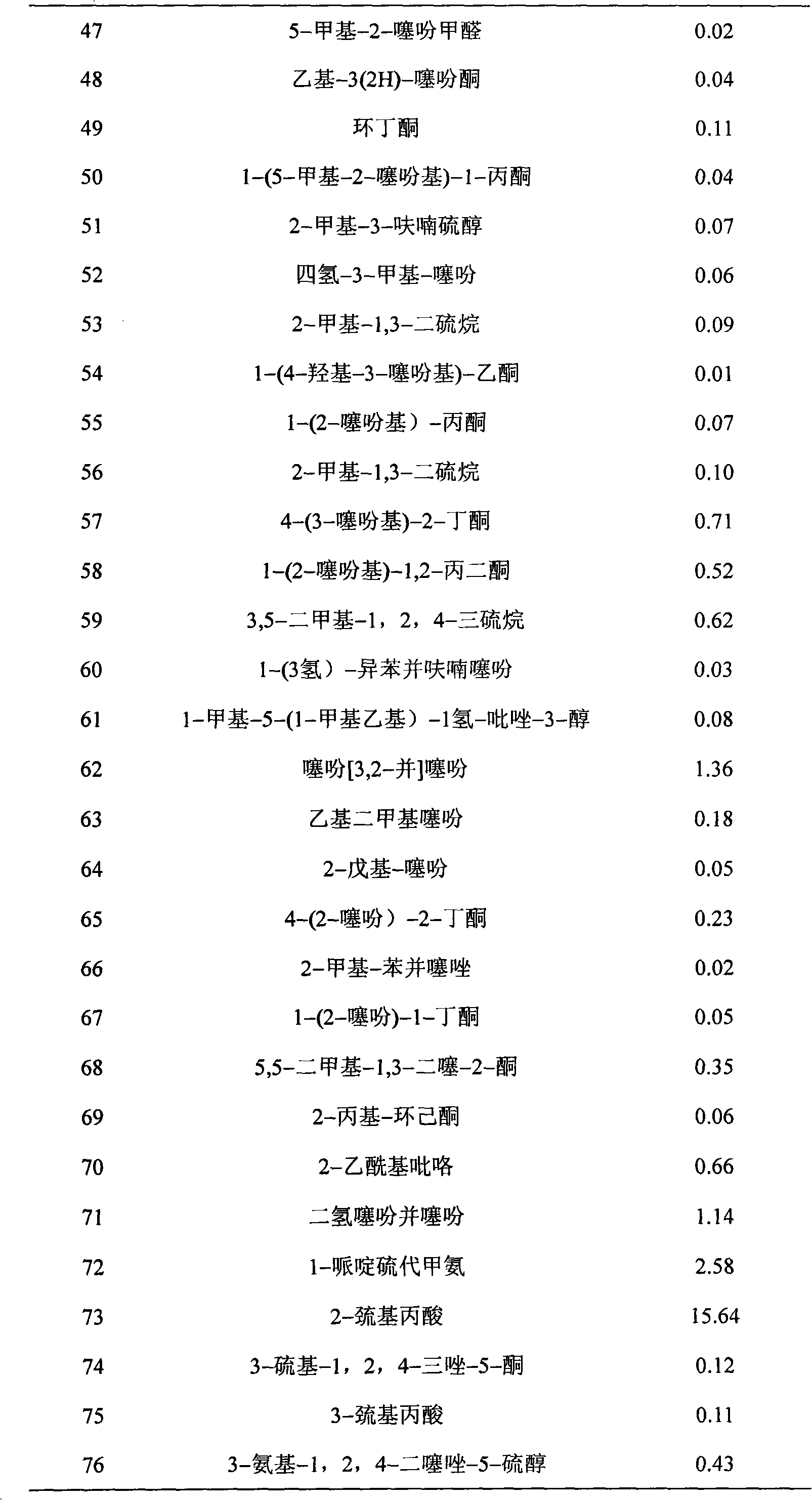

Image

Examples

Embodiment 1

[0030] Cysteine and glucose are dissolved together in a mixed solvent of propylene glycol and water (propylene glycol: water = 5: 1) by mass percentage 10.0% and 5.0%, put in a pressure reactor with a stirring and heating device, at 130 Carry out the Maillard reaction at ℃ and 500rpm, and carry out the reaction for at least 1h to obtain the Maillard reactant, then cool the above reactant to below 100°C, discharge the material, put it in a heat-resistant sealed bottle, and let it stand at room temperature for at least After 1 hour, the upper transparent liquid phase was separated to obtain the milk fragrance flavoring agent of the present invention.

[0031] Add the flavor enhancer of the milk fragrance in the present invention with 0.08wt% of protein milk content in milk products to prepare a kind of milk liquid with 0.08wt% of protein content in milk products added with flavor enhancer. The milk with flavor enhancer was used as blank comparison. Ask professional sensory ev...

Embodiment 2

[0037] The acid hydrolyzate of cysteine and sucrose is mixed and dissolved in the mixture of propylene glycol and water (propylene glycol: water = 5: 1) by mass percentage 15.0% and 10%, to form a 100% homogeneous reaction solution, which is dropped into the belt with stirring and In the pressure reactor of the heating device, carry out the Maillard reaction at 130°C and 500rpm for at least 1 hour to obtain the Maillard reactant, then cool the above reactant to below 100°C, discharge the material, and install it in a heat-resistant Put it in a sealed bottle, let it stand at room temperature for at least 1 hour, separate the upper transparent liquid phase, and obtain the milk fragrance flavoring agent of the present invention.

[0038] Add the above-mentioned milk fragrance flavoring agent with 0.08wt% of the protein milk content in dairy products to prepare a milk with 0.08wt% of the protein content in dairy products with flavoring agent added, while adding no The milk with ...

Embodiment 3

[0041] Methionine and glucose are mixed and dissolved in a mixed solvent of propylene glycol and water (propylene glycol: water = 5: 1) according to the mass percentage of 15.0% and 10%, to form a 100% uniform reaction solution, which is put into a pressure reactor with a stirring and heating device , carry out Maillard reaction at 130°C and 500rpm, and carry out the reaction for at least 1h to obtain the Maillard reactant. Stand still for at least 1 h, separate the upper transparent liquid phase, and obtain the milk flavor flavoring agent of the present invention.

[0042] Add the above-mentioned milk fragrance flavoring agent with 0.08wt% of the protein milk content in dairy products to prepare a milk with 0.08wt% of the protein content in dairy products with flavoring agent added, while adding no The milk with flavor enhancer was used as a blank for comparative evaluation. Ask professional sensory evaluation technicians (more than 8 people each time) to evaluate, and use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com