Warp knitted fabric and apparel making use of the same

A warp knitted fabric and weave technology, applied in the direction of warp knitting, knitting, protective clothing, etc., can solve the problems of inability to form goods, detachment, and easy curling of the cutting end, so as to prevent the occurrence of fray and prevent fray. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

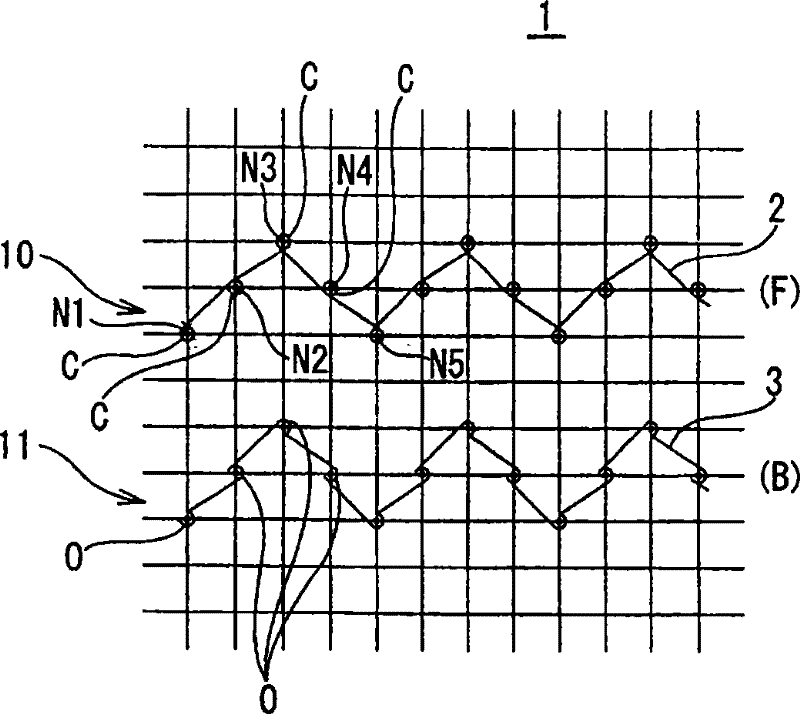

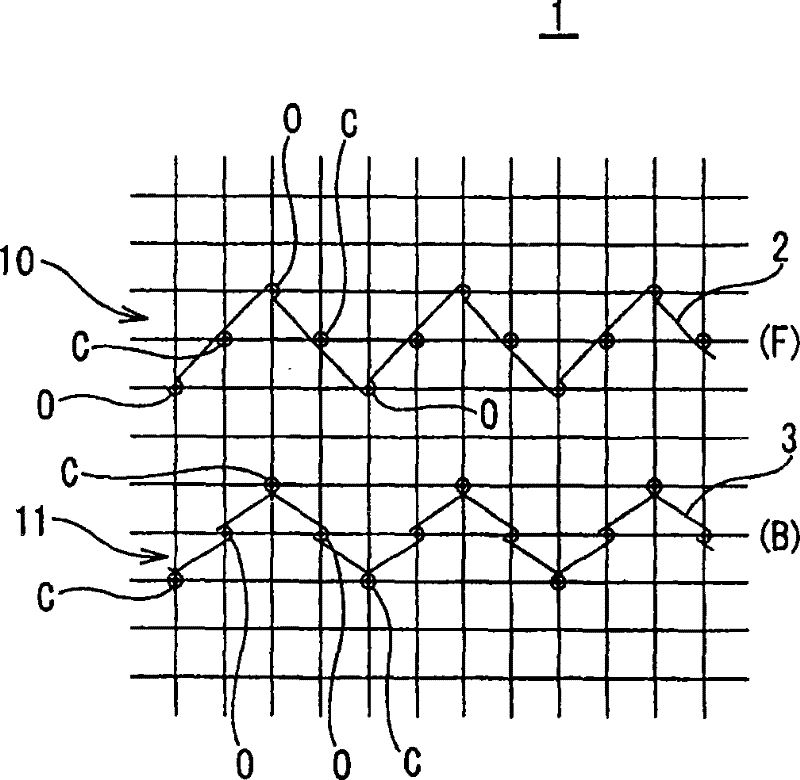

[0080] figure 1 The knitting structure of the warp knitted fabric 1 of the first embodiment is shown, in which the base fabric structure F is woven with the inelastic yarn 2 by the front reed 10, and the base fabric structure B is woven with the elastic yarn by the back reed 11.

[0081] Both the inelastic yarn 2 and the elastic yarn 3 are made into a 4-row satin weave and are weaved in parallel. X in the figure is the knitting direction of the fabric.

[0082] In addition, all the inelastic yarns 2 are made into closed loops C, and all elastic yarns 3 are made into open loops O, and the closed loops are not overlapped.

[0083] In detail, the inelastic yarn 2 is run obliquely upward and rightward in the figure across two courses from the first needle N1 to the second needle N2, from the second needle to the third needle, by the surface reed 10, from The 3r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com