Separating explosion-proof skid-mounted type vehicle gasification device

A technology for blocking explosion-proof and gas filling devices, which is used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., and can solve the problems of boiling liquid expansion steam explosion, difficult construction, and large footprint. , to achieve the effect of preventing corrosion, shortening the construction time and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

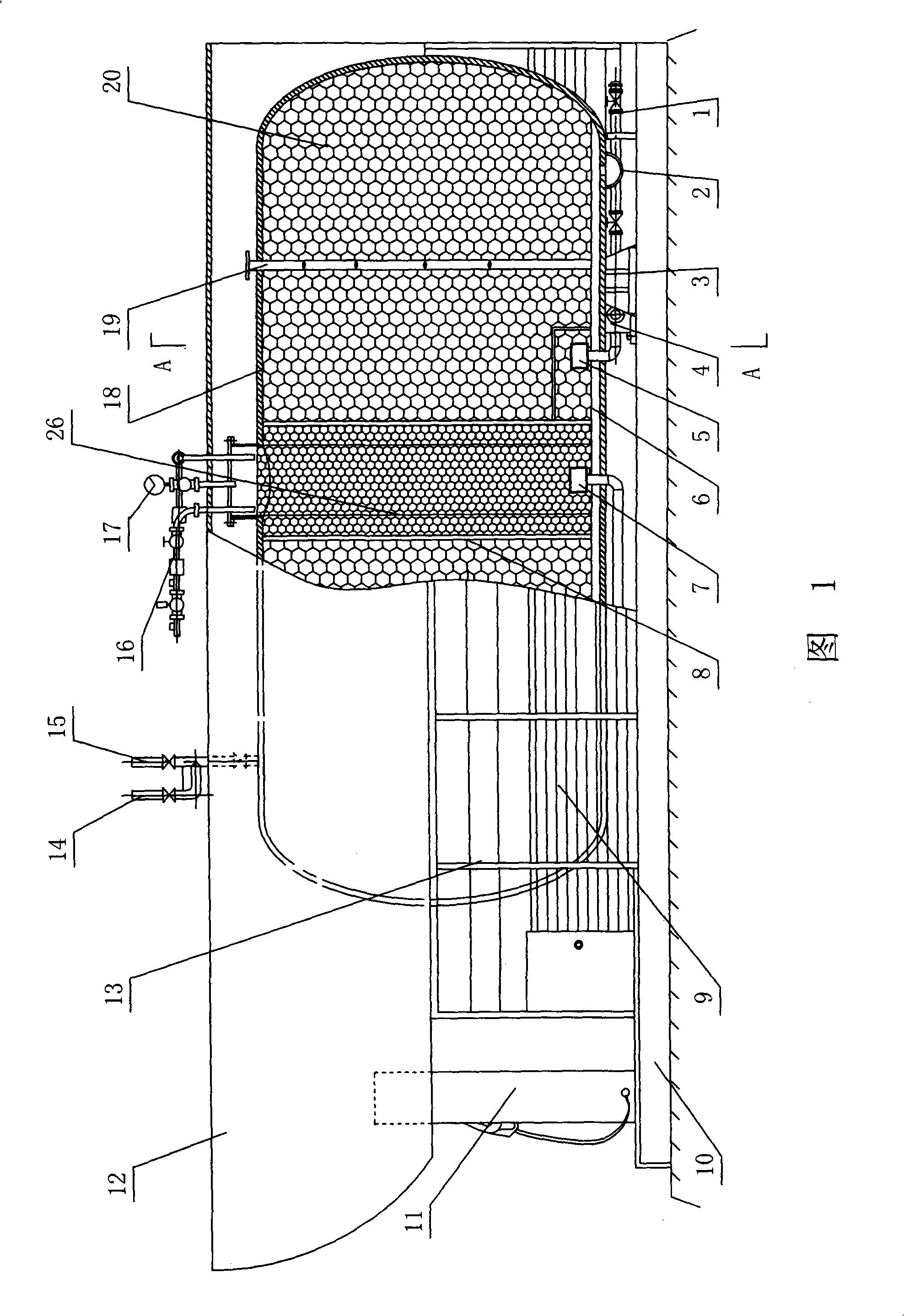

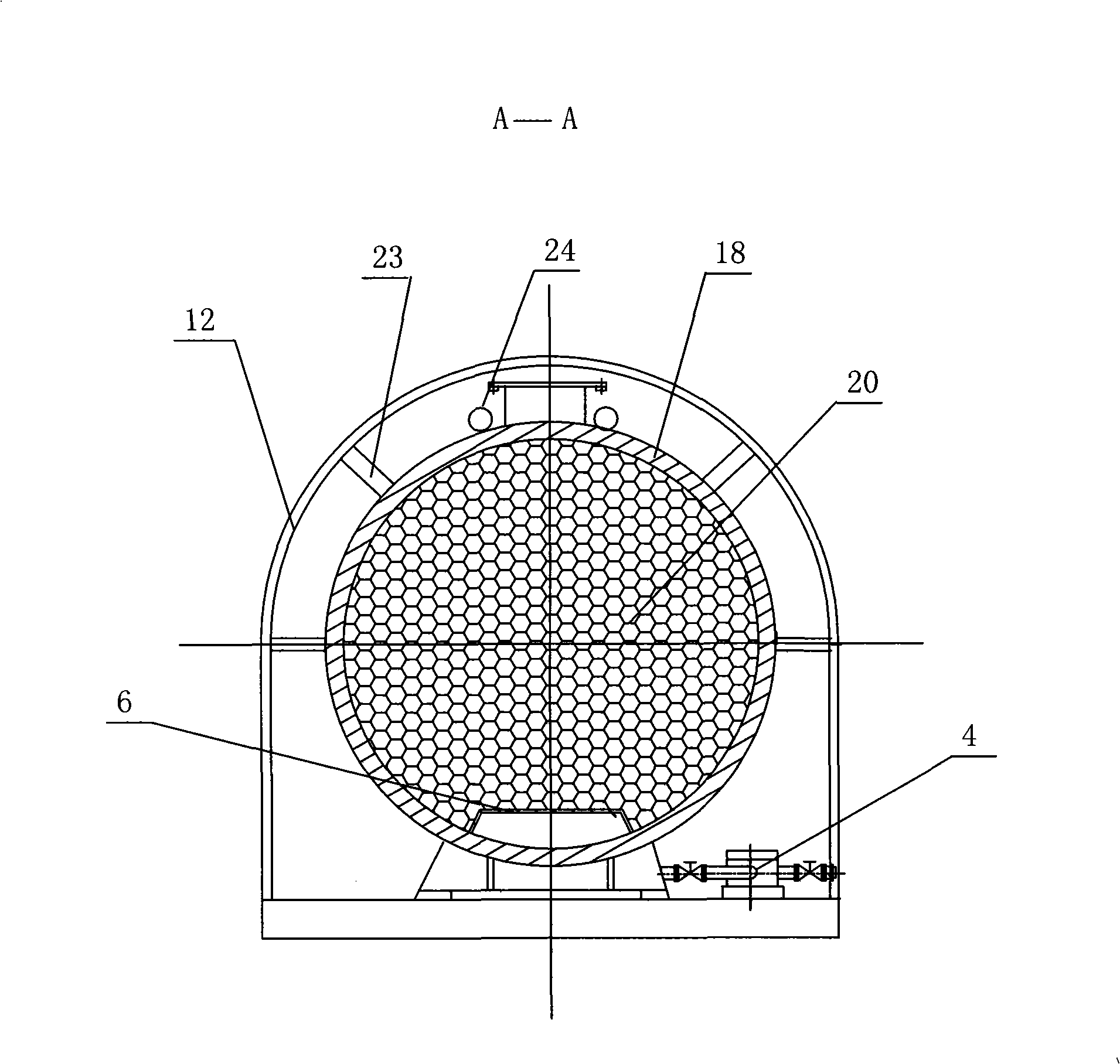

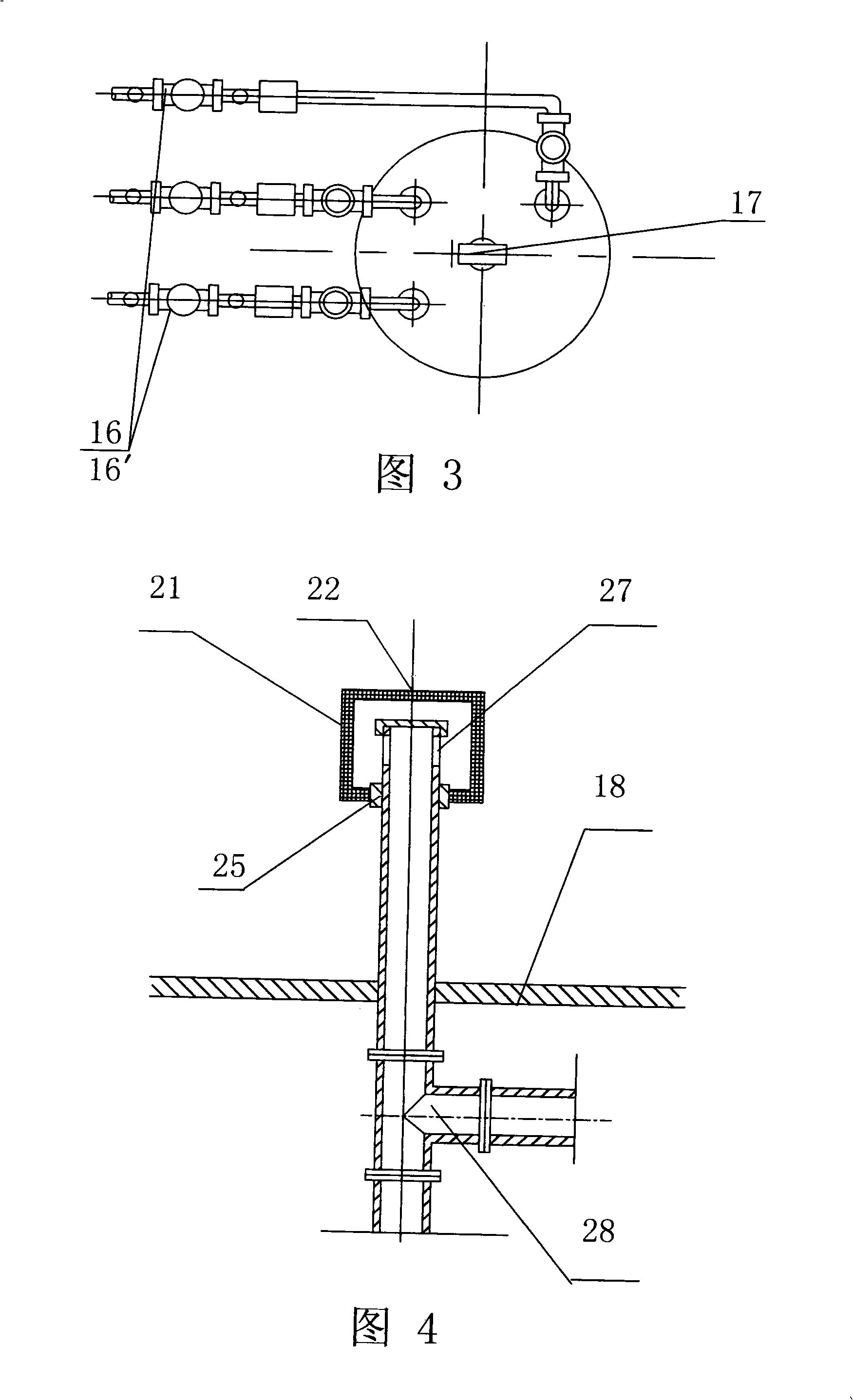

[0036] In conjunction with accompanying drawing 1-7, the specific embodiment of the barrier explosion-proof skid-mounted automobile gas filling device of the present invention is illustrated:

[0037] The barrier explosion-proof skid-mounted automobile gas filling device of the present invention comprises a barrier explosion-proof gas storage tank 18, a gas filling machine 11, a skid body 10, a protective cover 13, a sun-proof and heat-insulation tent 12 and auxiliary equipment. The barrier explosion-proof skid-mounted vehicle gas filling device is an overall skid-mounted, ground-level gas supply equipment. The barrier explosion-proof gas storage tank 18 and the gas dispenser 11 are seated on the skid body 10 . The skid body 10 is a rectangular frame made of channel steel, with longitudinal and transverse reinforcing ribs arranged in the middle, patterned steel plates are laid on the frame, and the frame is fixed on the anti-collision foundation by bolts. The skid body 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com