Soil pressure balance shield machine back loading type cutter head foam spraying device

A technology of earth pressure balance and shield machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., and can solve problems such as failure of foam devices, blockage of foam nozzles, and inability to replace them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

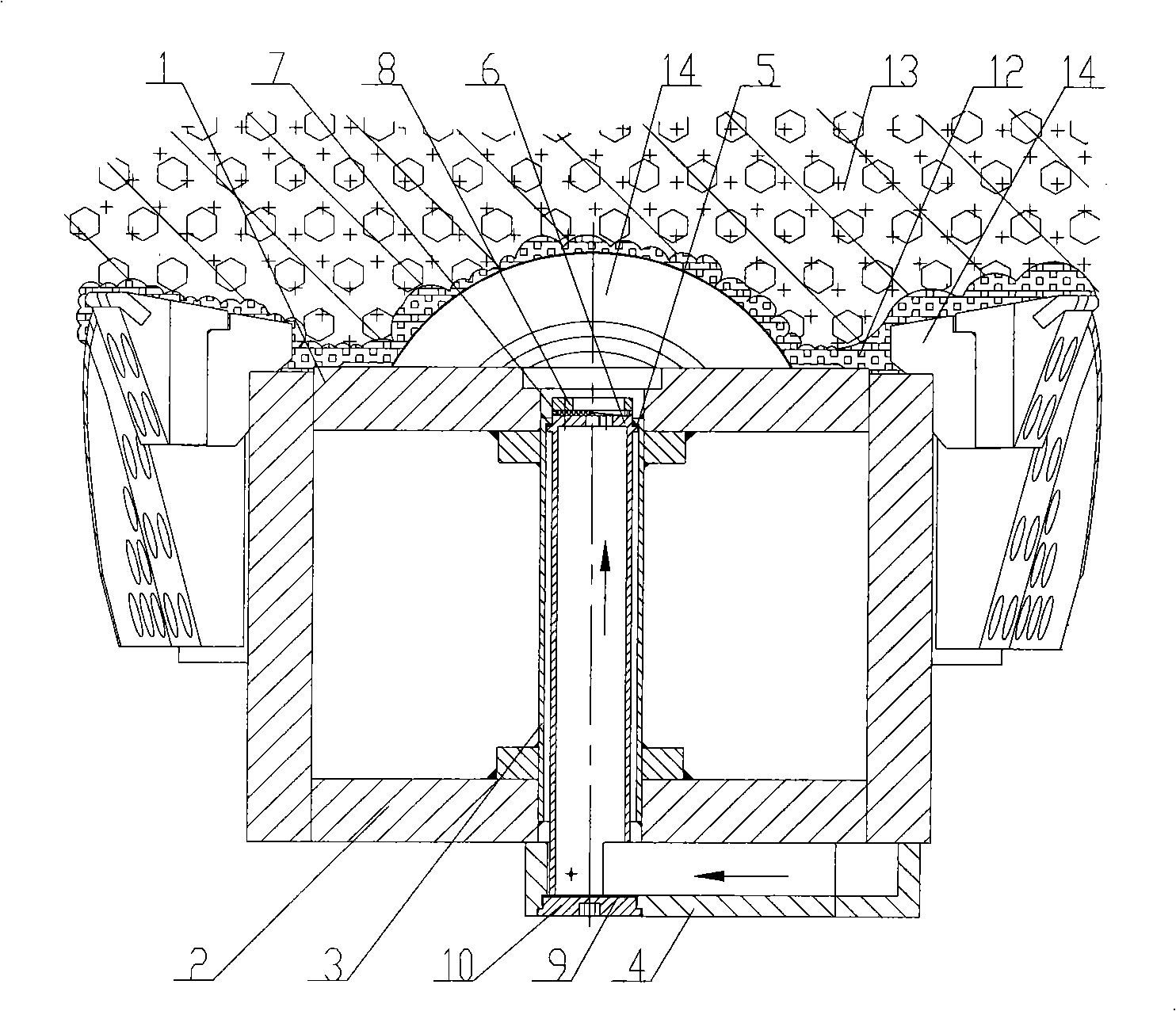

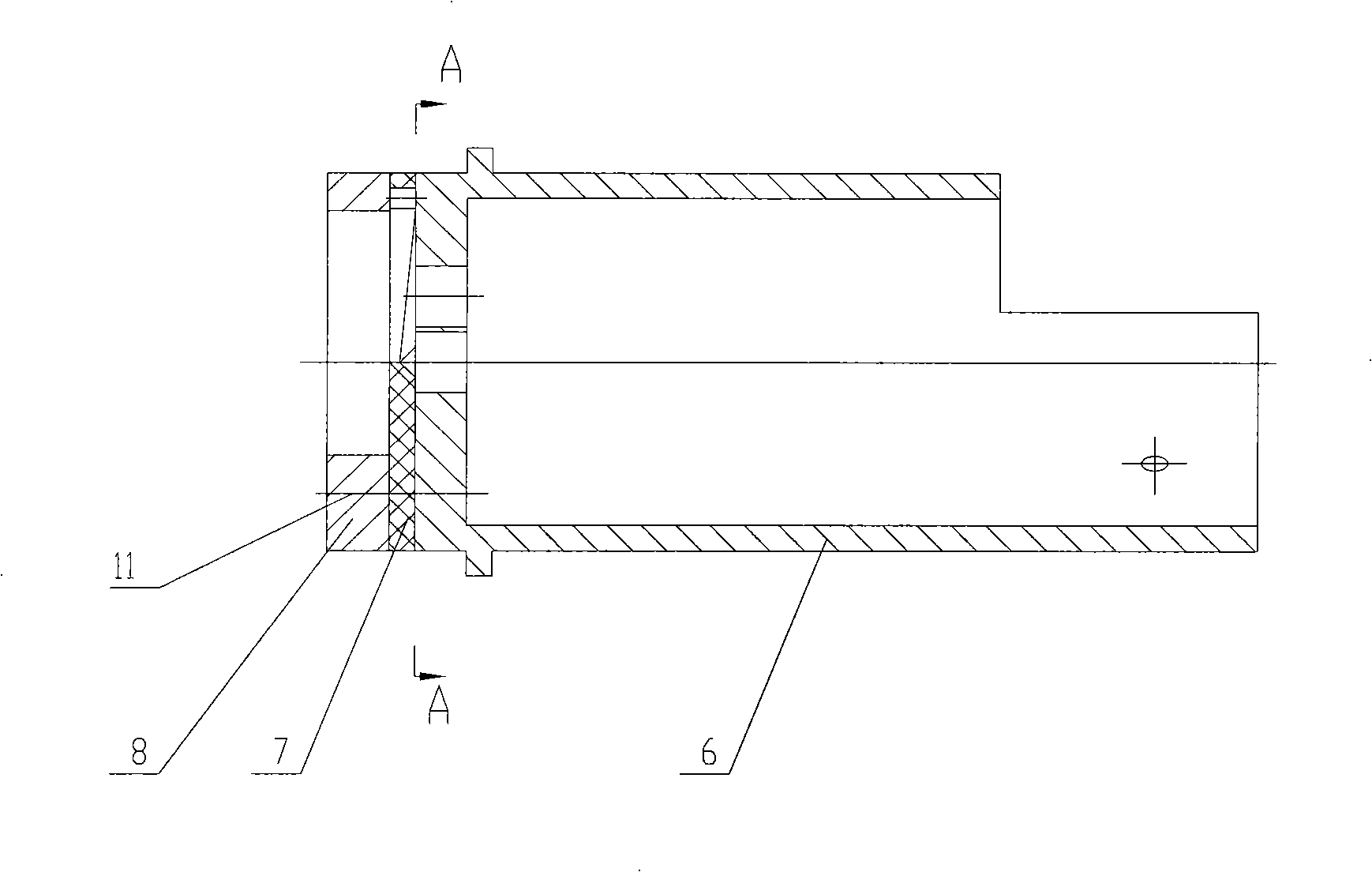

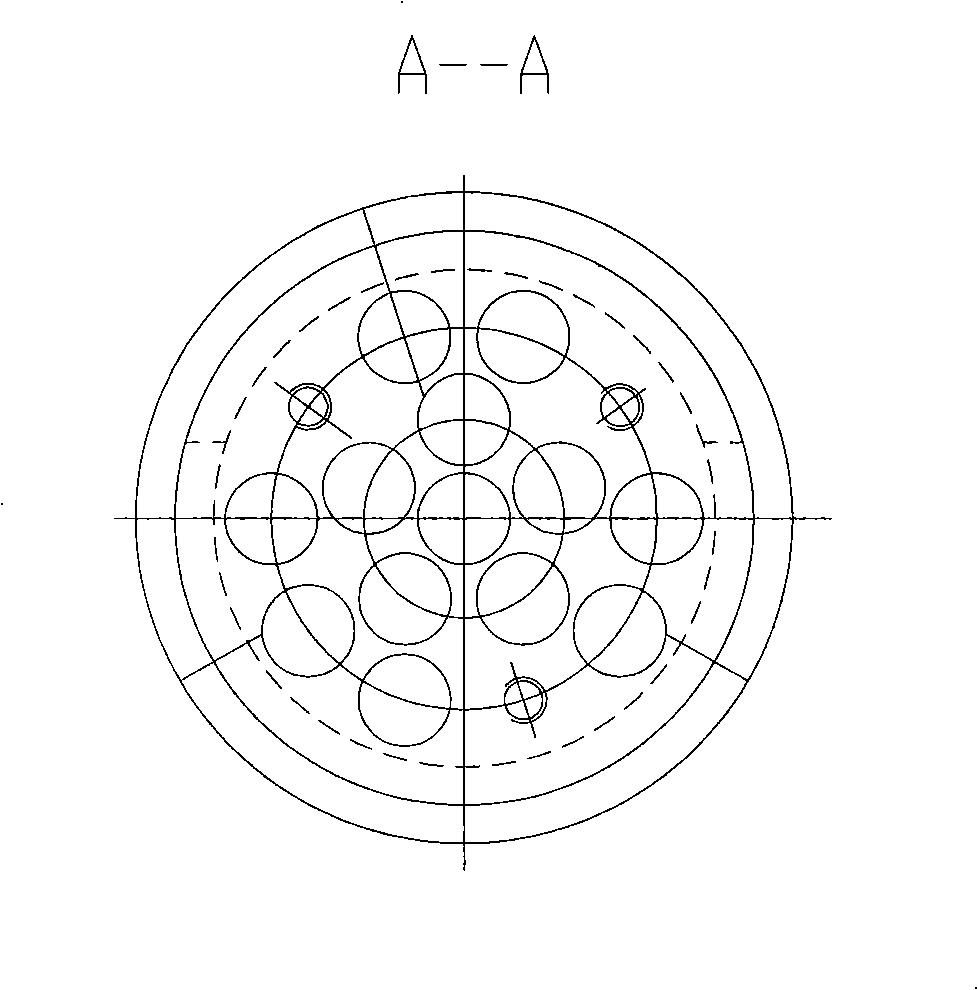

[0012] Referring to the accompanying drawings, the back-mounted cutter head foam injection device of the earth pressure balance shield machine consists of a front panel of the cutter head 1, a steel pipe with a stopper flange in the inner hole 2, a back panel of the cutter head 3, and a sealing threaded hole. Foam pipe box 4, sealing ring 5, sleeve with opening at the end of foam nozzle 6, diaphragm 7, flange 8, sealing gasket 9, sealing fixing screw plug 10, screw 11, foam 12, excavation face 13. The tool 14 is composed of a steel pipe 2 with a spigot flange in the inner hole. The spigot flange end is connected to the front panel 1 of the cutter head, and the other end is connected to the back panel 3 of the cutter head. A foam pipeline with a sealed threaded hole The box 4 is connected to the back panel 3 of the cutter head. When connecting, the steel pipe 2 with a seam flange in the inner hole is concentric with the sealing threaded hole of the foam pipeline box 4 with a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com