Nozzle for jet fabric dyeing machine

A jet dyeing machine technology, applied in liquid/gas/steam jet propulsion fabric, spray/jet textile material treatment, textile material treatment, etc., can solve dyeing unevenness and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Fig. 1 shows a side view of an example of a conventional jet-type fabric dyeing machine. The machine 1 comprises a cylindrical main chamber 11 and a travel tube 13 of smaller diameter arranged below the main chamber 11 and connected to each end of the main chamber 11 . The main chamber 11 and the travel tube 13 thus form a continuous enclosed path around which endless fabric ropes can circulate while in contact with the dye liquor or another treatment fluid. The fabric is dyed or otherwise treated during the designated processing time that circulates around the machine.

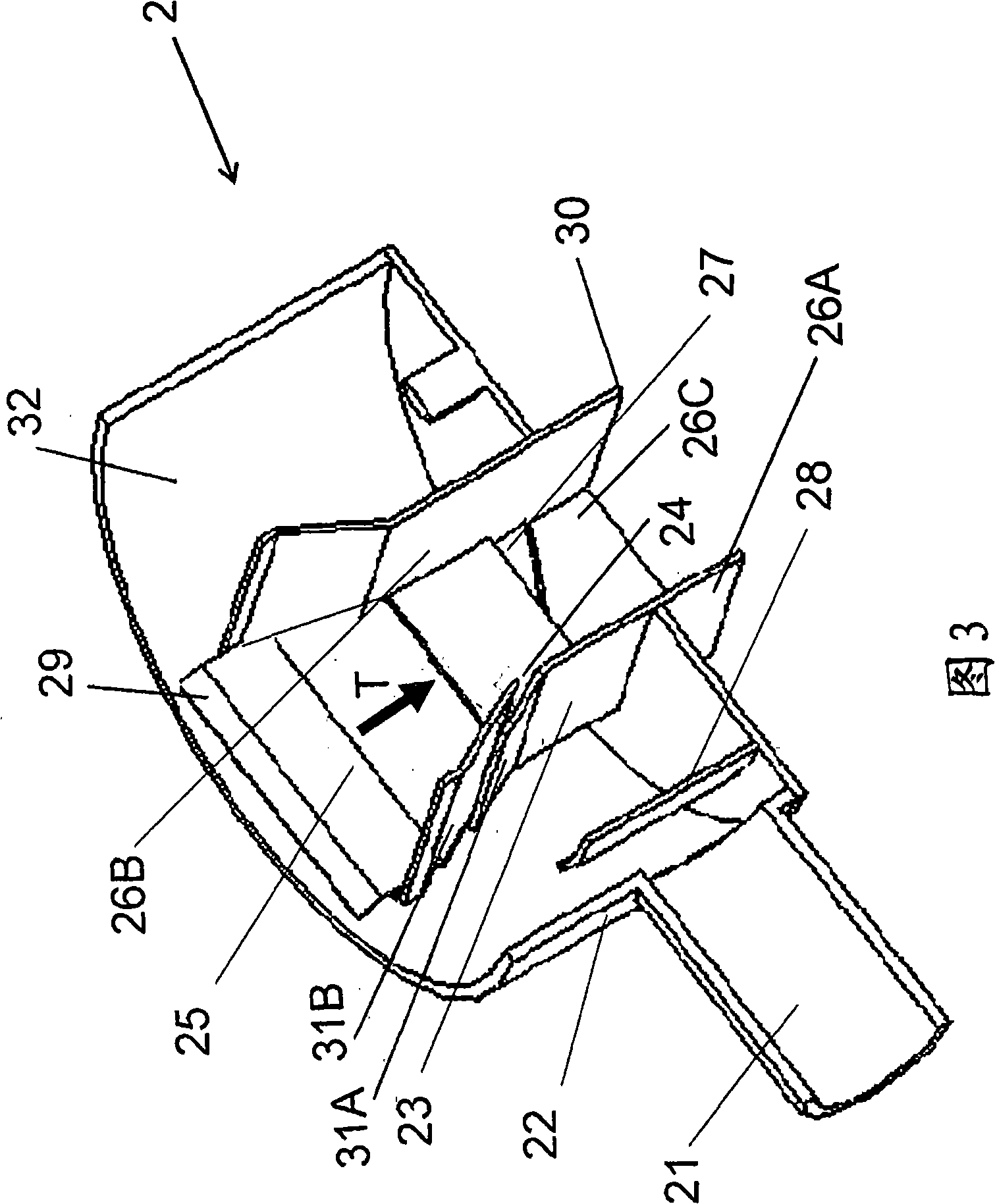

[0026] The fabric rope is propelled around the machine along the travel path by a nozzle assembly 12 located at one end of the main chamber 11 at the entrance to the travel tube 13 . Nozzle assemblies traditionally comprise a tubular nozzle member through which the fabric passes (the nozzle member thereby forming part of the path of travel of the fabric). A jet of high pressure fluid (eg dye liquor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com