Rotatable face milling cutter made of superhard material

A technology of superhard materials and face milling cutters, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of inability to process higher hardness superhard materials and unstable milling cutter structures, and achieve outstanding technical effects. Improve processing hardness and strength, improve the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

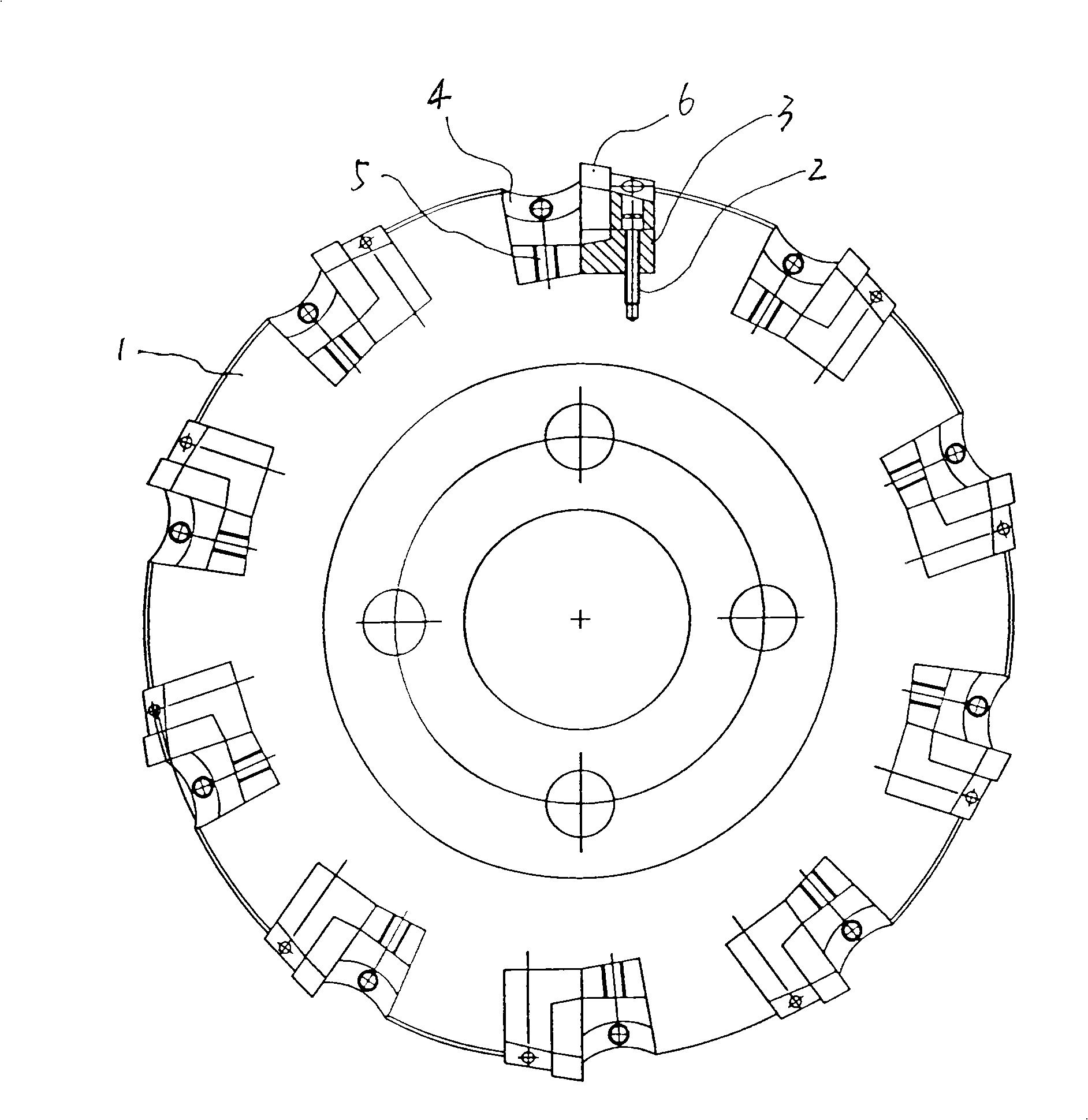

[0015] like figure 1 As shown, an indexable face milling cutter made of superhard material is provided with several installation grooves on the outer wall of the periphery of the cutter body 1, and a module 3 is fixed with a fastening screw 2 on one side of each installation groove, and a wedge is arranged on the other side. Block 4, the lower part of the wedge block 4 is connected to the cutter body 1 through the threaded column 5, a step is arranged on the module 3, and the blade 6 is placed on the step, and the two contact surfaces of the wedge block 4 and the cutter body 1 and the blade 6 are inclined planes or one of them One contact surface is an inclined plane, and the wedge block 4 presses the blade 6 tightly. The threads at both ends of the threaded post 5 are in opposite directions, so turning the threaded post 5 can make the wedge 4 move downward. Because the contact surfaces of the wedge 4 and the cutter body 1 and the blade 6 are inclined surfaces, or one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com