Electric element carrier plate and manufacturing method thereof

A technology of electrical components and manufacturing methods, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuits connected with non-printed electrical components, etc. , low cost, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

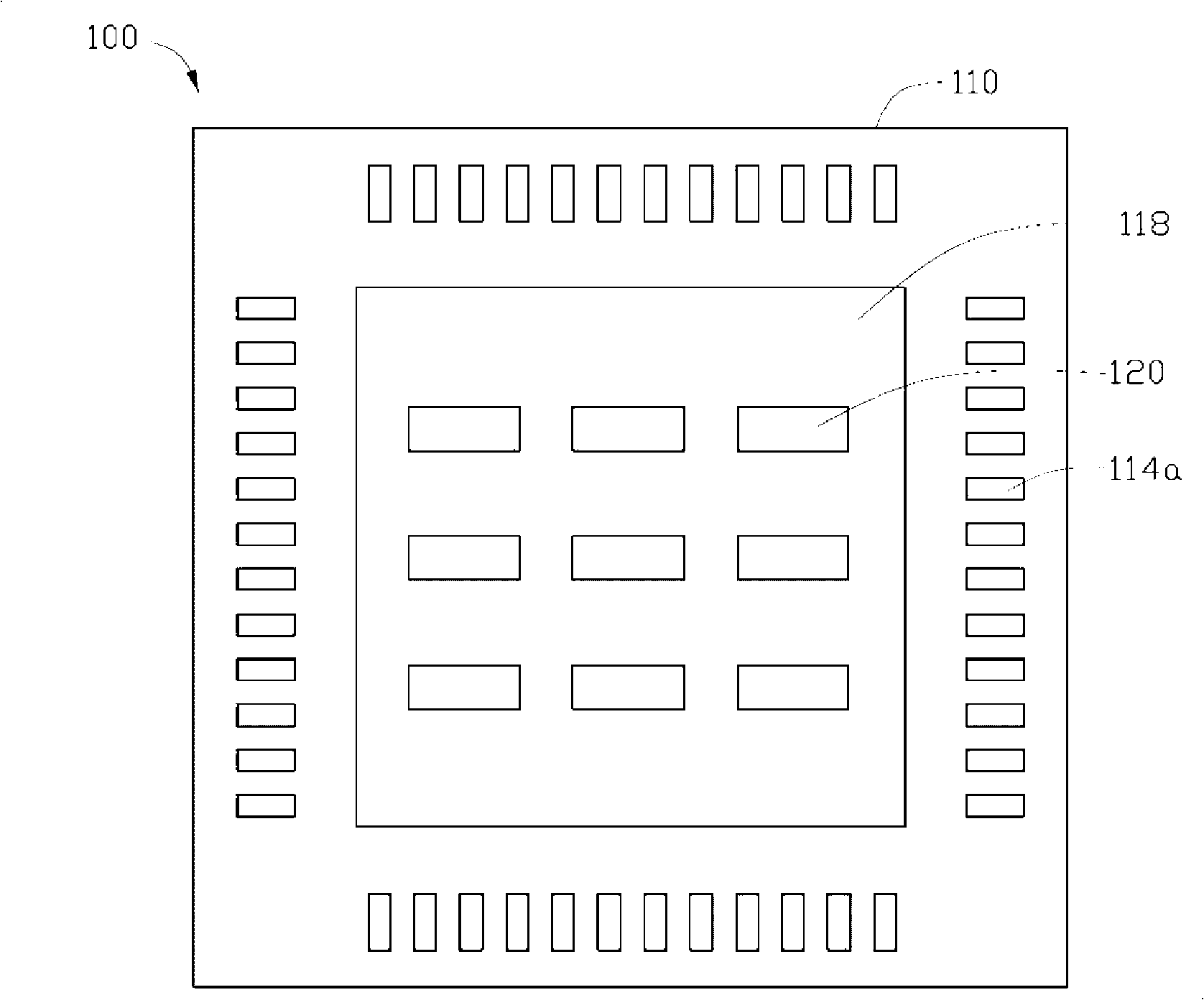

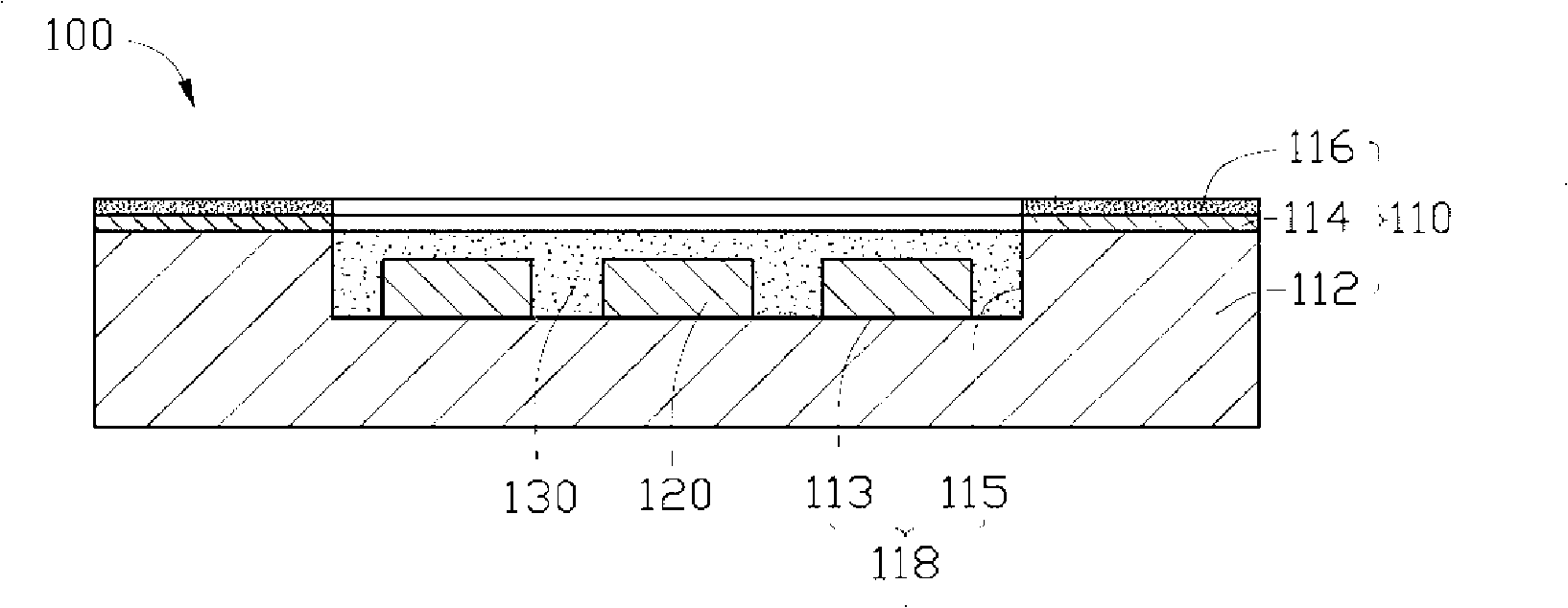

[0019] see figure 2 and image 3 , the first preferred embodiment of the electrical component carrier 100 of the present invention. The electrical component carrier 100 includes a base 110 , at least one passive component 120 and a filling material 130 .

[0020] The substrate 110 is a printed circuit board, which can be any circuit board used in the industry, such as phenolic resin copper clad board, epoxy resin copper clad board, glass cloth epoxy resin copper clad board, polyester Imide resin copper clad board, copper clad PTFE glass cloth laminate, ceramic substrate, aluminum oxide nitride substrate (ALN), silicon carbide substrate (SiC) and other circuit boards. The substrate 110 includes a base layer 112 , a conductive layer 114 and a solder resist layer 116 , the conductive layer 114 is disposed on the base layer 112 , and the solder resist layer 116 is disposed on the conductive layer 114 . The conductive layer 114 is provided with a plurality of welding spots 114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com