Tube joint

A technology of pipe joints and inner joints, applied in the field of pipe joints, can solve problems such as difficult disassembly, and achieve the effect of safe and easy disassembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

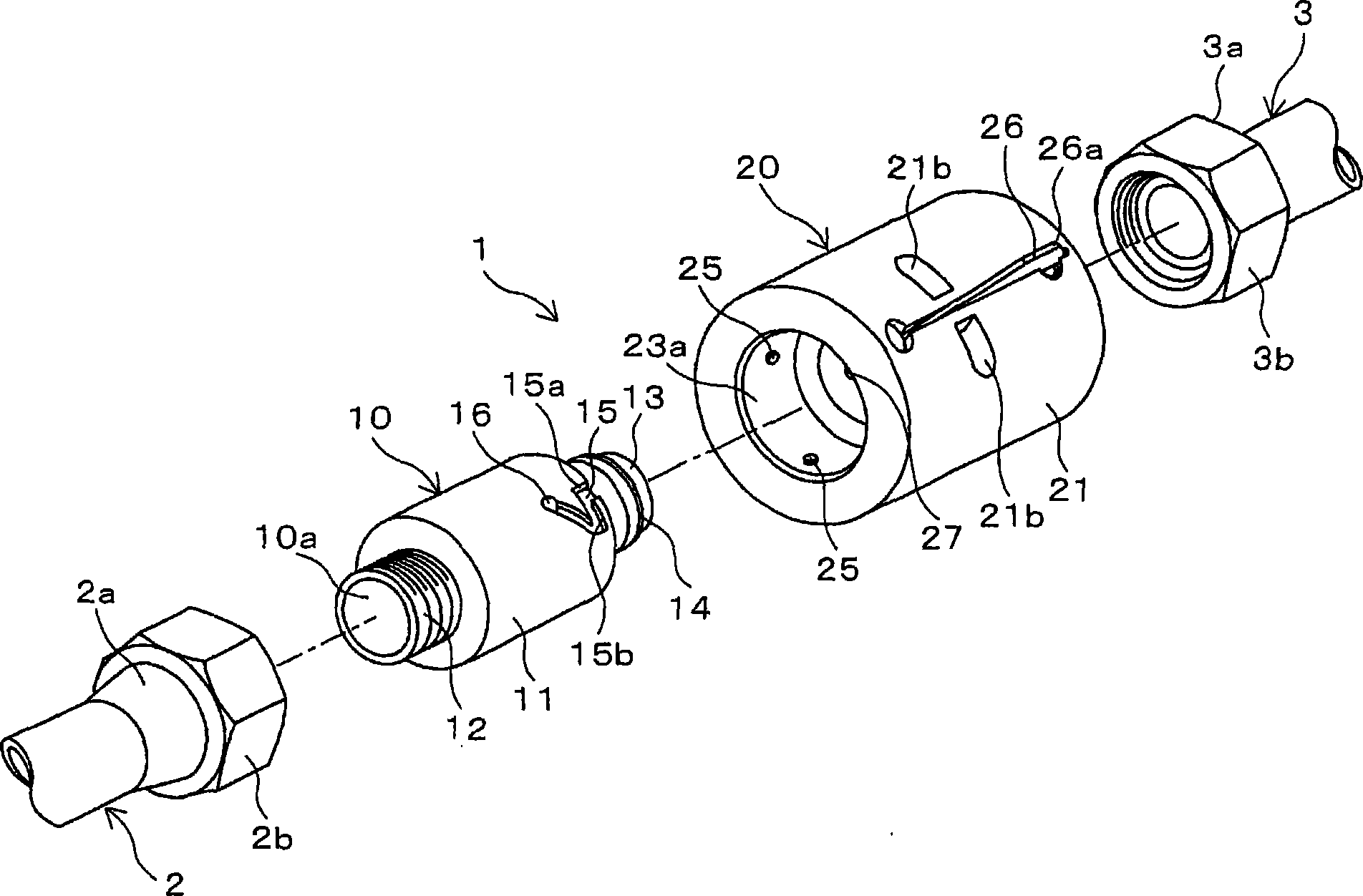

[0024] figure 1 It is a perspective view showing each member and pipe bodies 2 and 3 constituting the pipe joint 1 according to one embodiment. The pipe joint 1 is composed of a cylindrical inner joint 10 and a socket 20 . The inner joint 10 and the sleeve 20 of the pipe joint 1 are mounted on the front ends of the respective pipe bodies 2, 3 to detachably connect the pipe bodies 2, 3.

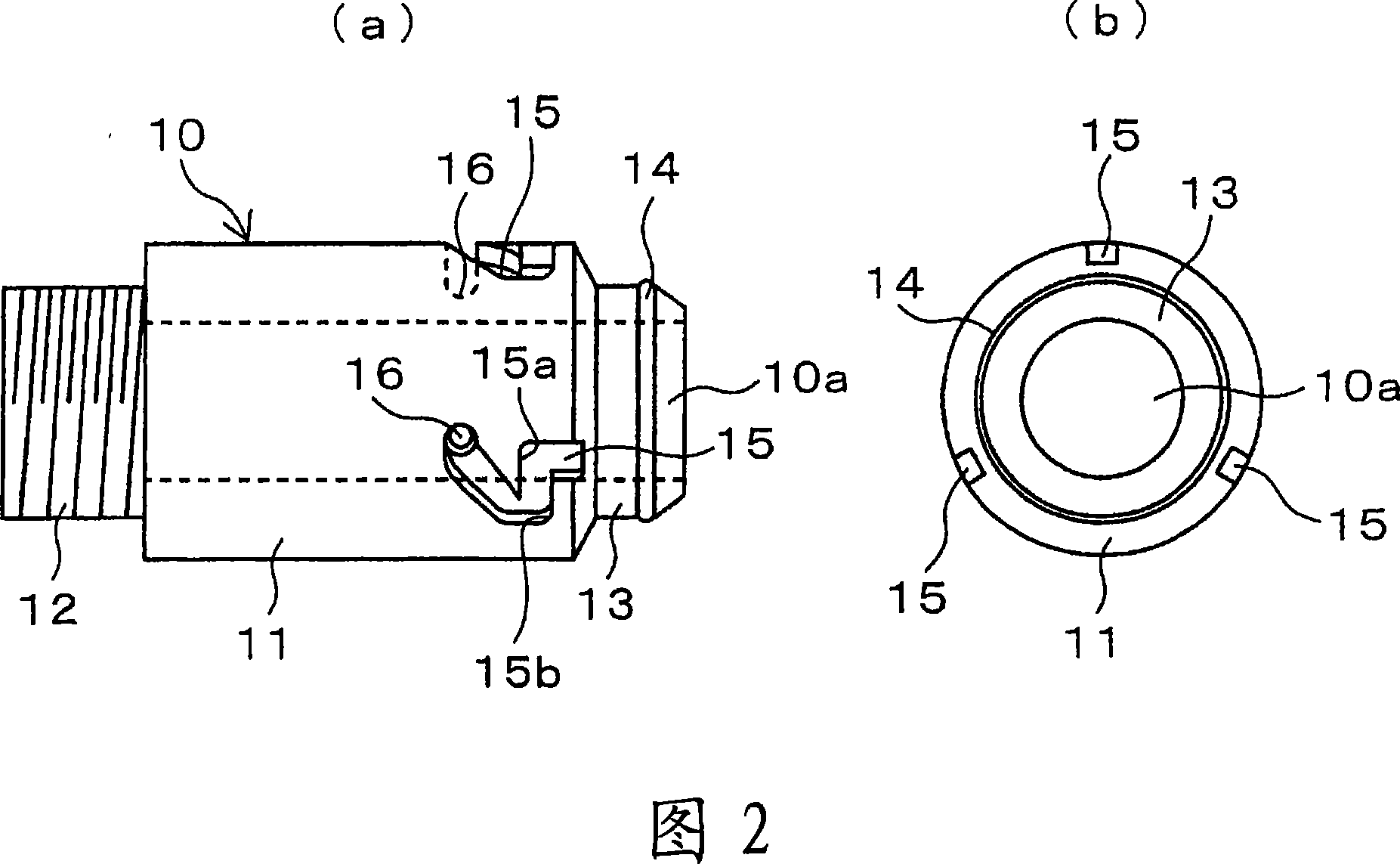

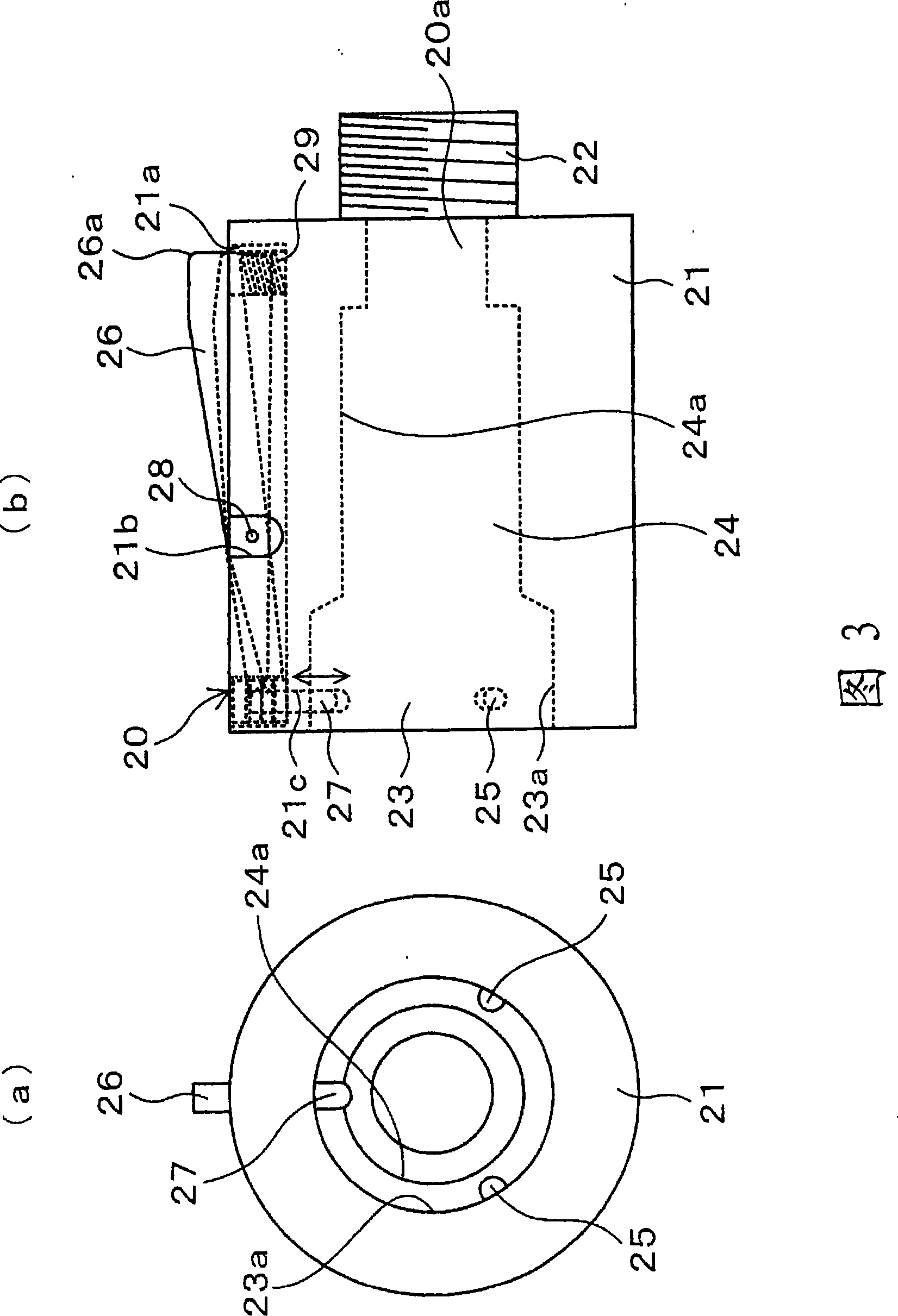

[0025] Connectors 2a, 3a integrally formed with nuts 2b, 3b are attached to the front ends of the pipe bodies 2, 3, respectively. The nipple 10 has a cylindrical large-diameter cylindrical portion 11 serving as a base, and a cylindrical thread portion 12 is coaxially formed at one axial end portion of the large-diameter cylindrical portion 11 . Further, the socket 20 has a cylindrical main body 21 serving as a base, and a cylindrical threaded portion 22 is coaxially formed at one axial end of the main body 21 (see FIG. 3 ). By screwing the nuts 2b, 3b of the couplings 2a, 3a on the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com