Battery pack, manufacturing method and disassembly method thereof

A manufacturing method and technology for battery packs, which are applied in the manufacture of secondary batteries, battery pack components, secondary batteries, etc., can solve problems such as damage, failure to maintain the confinement pressure of single cells, and plastic deformation of fastening members.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0042] [Battery]

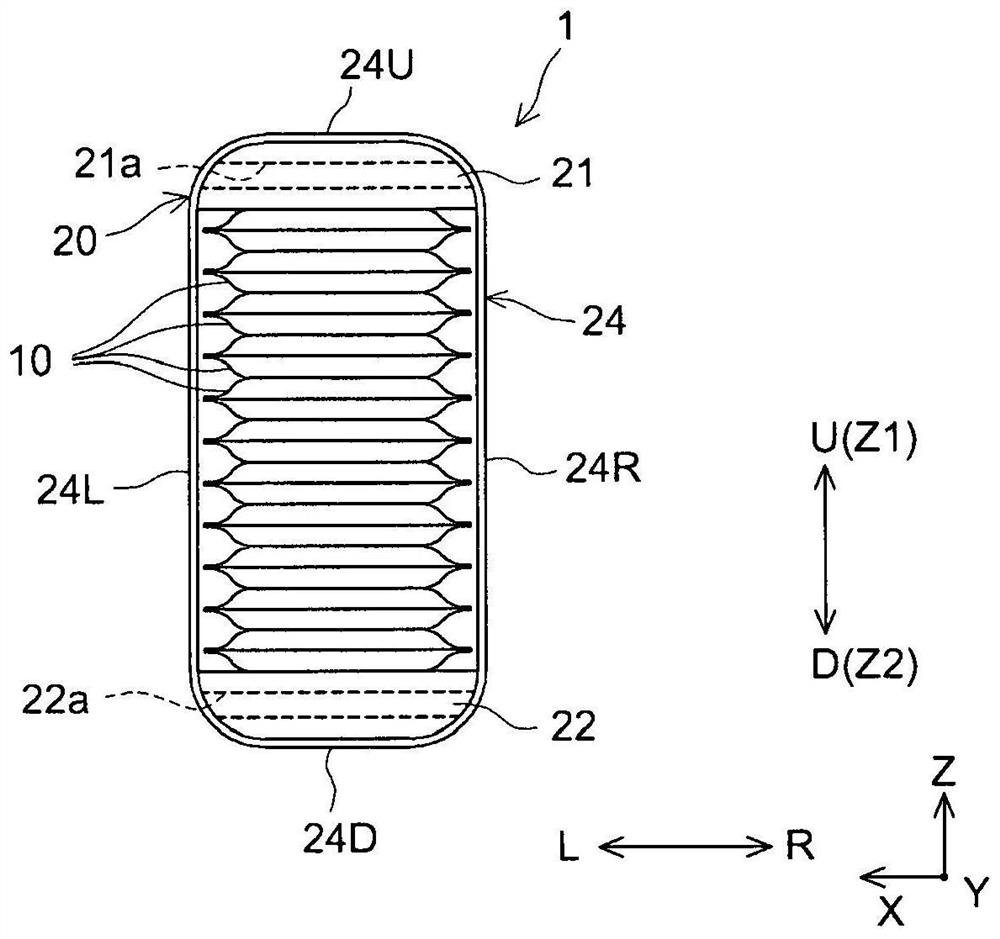

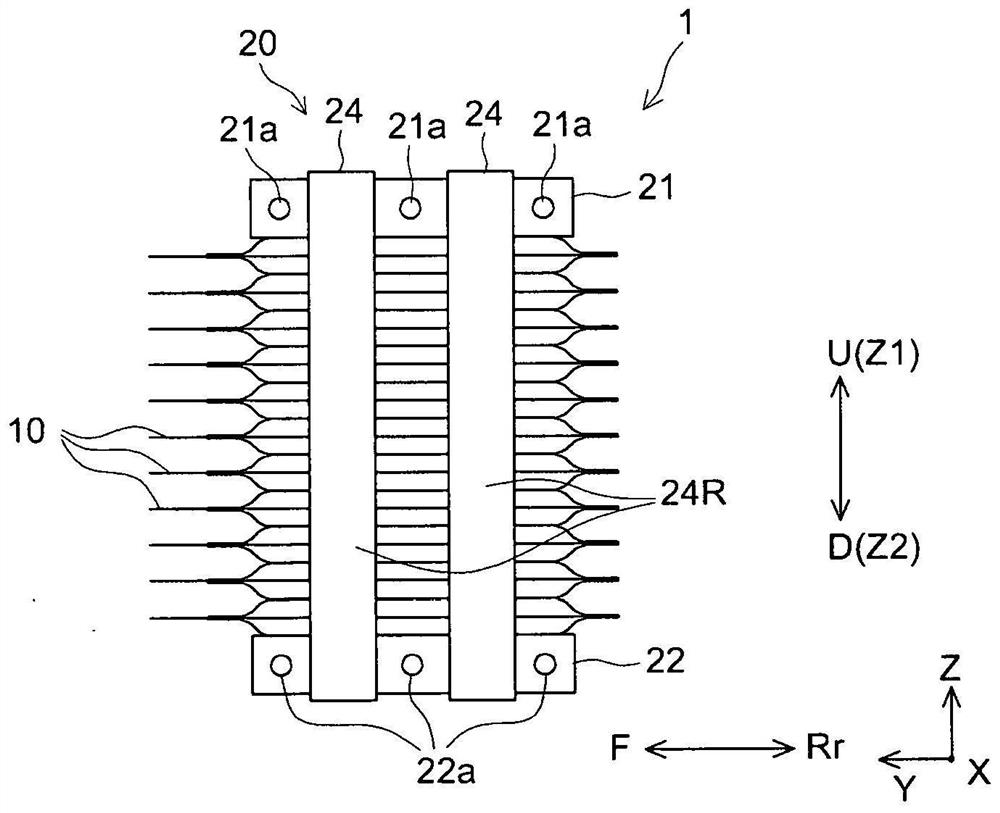

[0043] figure 1 is a front view schematically showing a battery pack 1 according to an embodiment, figure 2 is its side view. The battery pack 1 includes a plurality of single cells 10 and a restraint mechanism 20 . The plurality of single cells 10 are arranged along a predetermined arrangement direction Z. The restraint mechanism 20 is a member for restraining these single cells 10 so that they can be handled as a set of batteries. Each element will be described below.

[0044] [single battery]

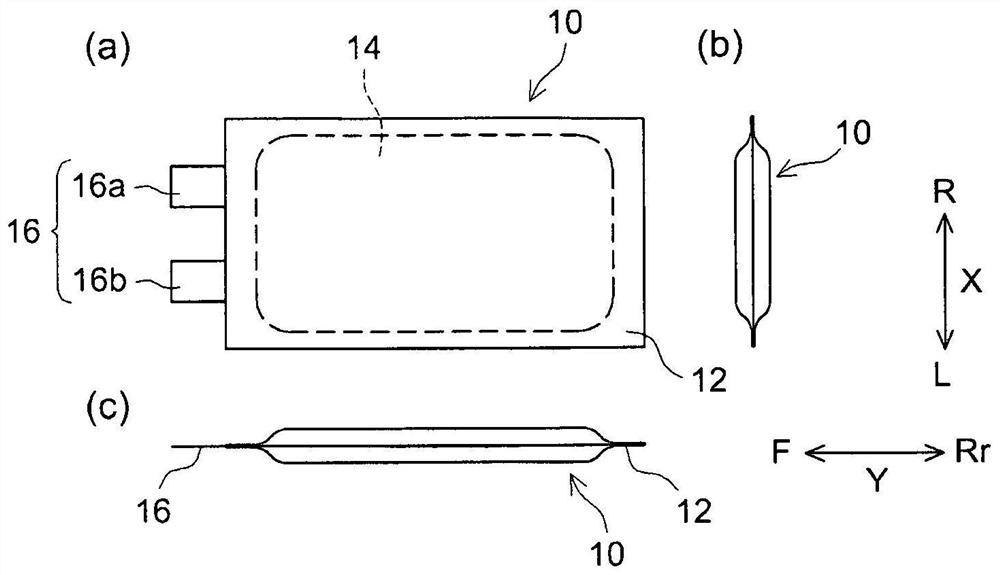

[0045] image 3 is a three-view diagram schematically showing the unit cell 10 . Typically, the cell 10 is a secondary battery that can be repeatedly charged and discharged, such as a lithium ion secondary battery, a nickel hydrogen battery, an electric double layer capacitor, or the like. In addition, for secondary batteries, in order to improve safety, the practical application of all-solid-state batteries is advancing. This all-solid-state battery does ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com