Apparatus and method for entire journey autotrophy denitrification of digested sludge dewatered liquid biomembrane

A technology for whole-process autotrophic denitrification and digested sludge is applied in the field of devices and methods for whole-process autotrophic denitrification of digested sludge dewatering liquid biofilm, which can solve the problem of low denitrification efficiency, increased sewage denitrification cost, and denitrification efficiency. It is difficult to improve and other problems to achieve the effect of improving the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

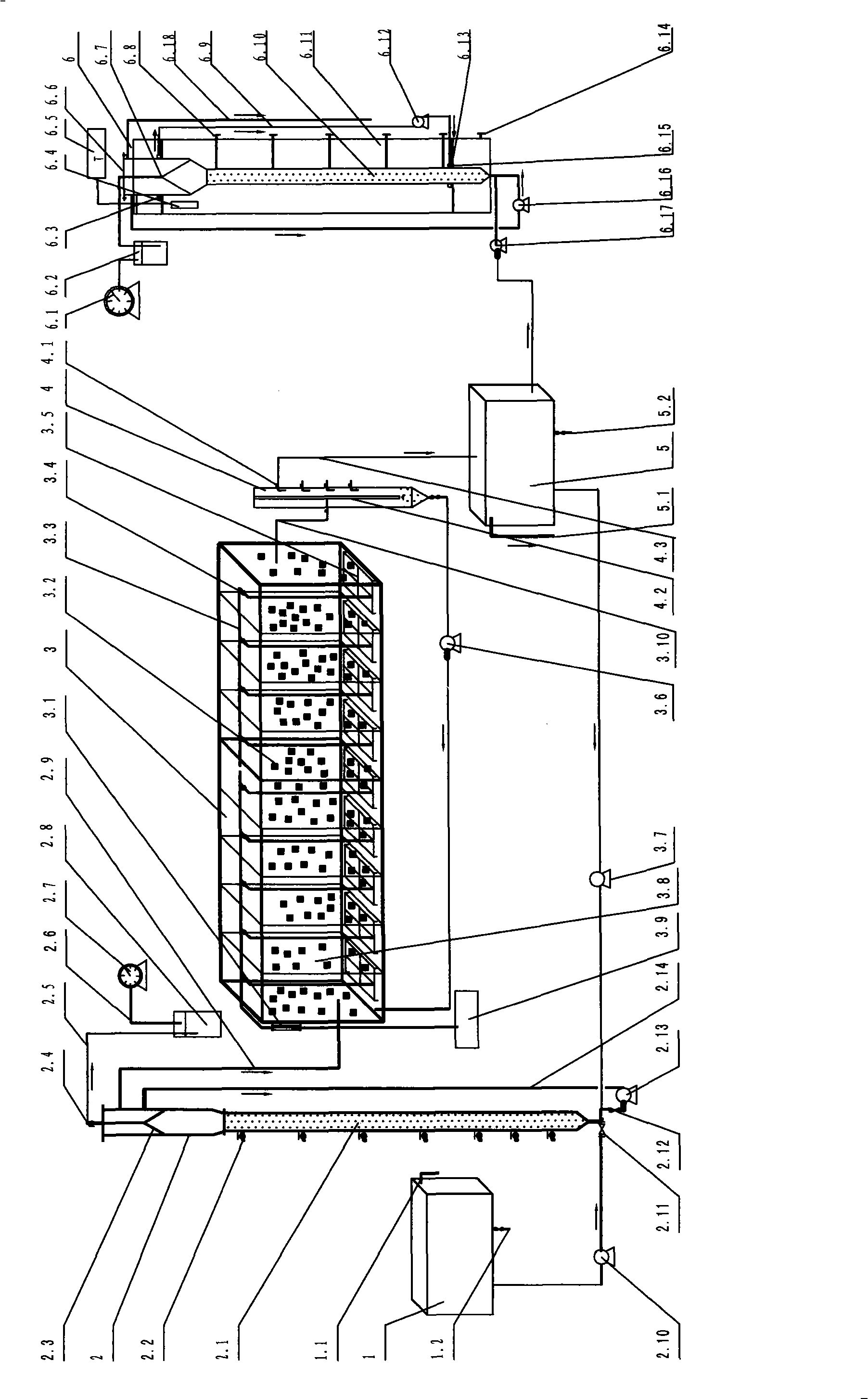

[0026] Below in conjunction with accompanying drawing and embodiment, the patent of the present application is further described: embodiment: as shown in Figure 1, the device for digesting sludge dewatering liquid biofilm whole process autotrophic denitrification, consists of digesting sludge dewatering liquid pool, pre-anoxic It is composed of denitrification tank, biofilm short-range nitrification tank, sedimentation tank, intermediate pool, and biofilm anammox tank. The effective volume of the digested sludge dewatering liquid tank is 700L, the effective volume of the pre-anoxic denitrification tank, the biofilm short-range nitrification tank and the biofilm anammox tank are 8L, 32L and 8.5L respectively, and the effective volume of the intermediate tank is 20L, the effective volume of the sedimentation tank is 15L. The size of the pre-anoxic denitrification tank is Φ×H=8cm×200cm, and the size of the biofilm short-range nitrification tank is L×B×H=80cm×10cm×55cm, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com