Cigarette packing machine and method for producing slide-open cigarette

A packaging method, a technology for cigarette boxes, applied in the directions of packaging, packaging cigarettes, transport packaging, etc., can solve the problems of expensive and high-cost production stagnation, machine cost and size doubling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

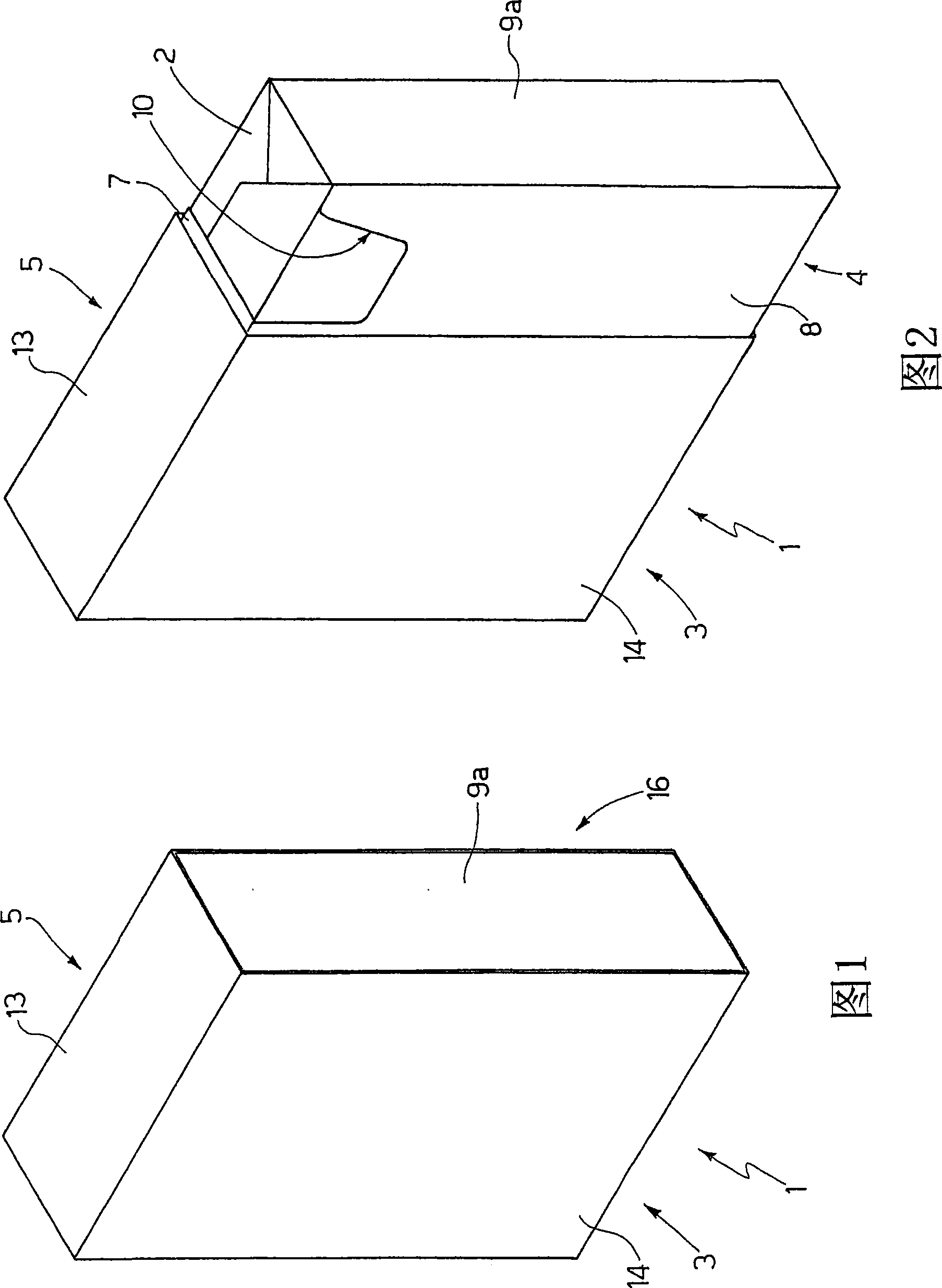

[0037] figure 1 The number 1 in indicates the whole of the rigid straight slide-open cigarette pack.

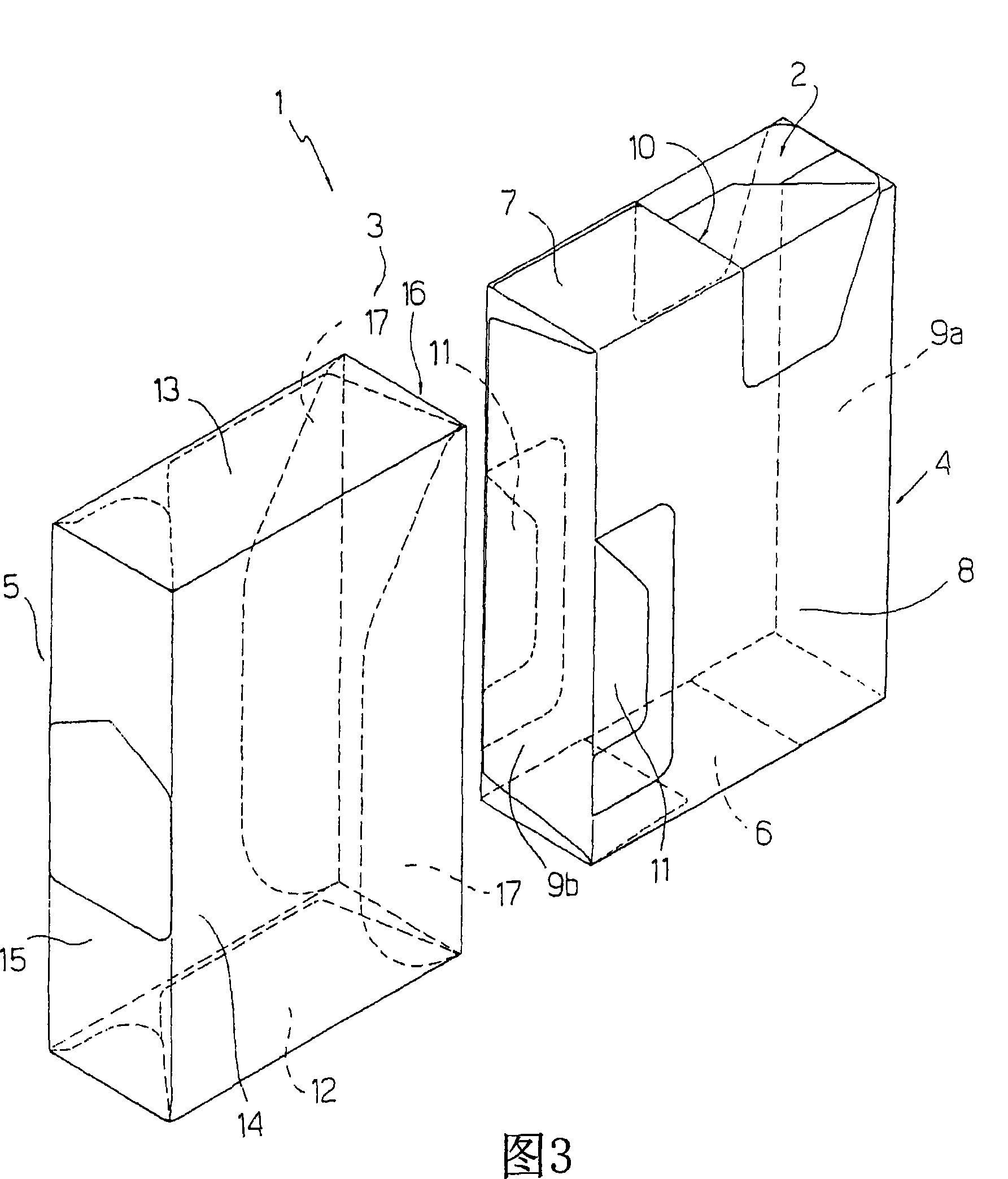

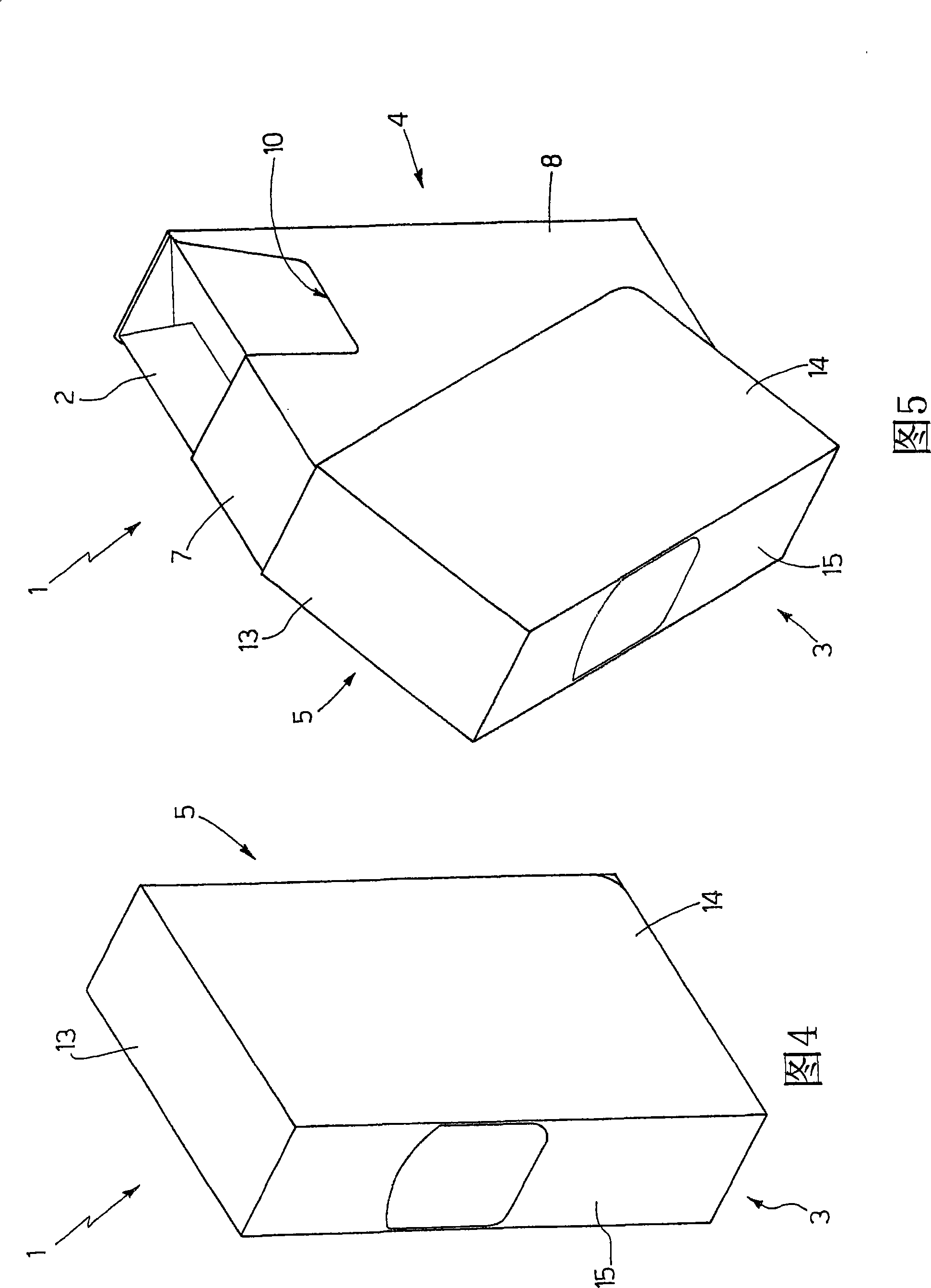

[0038] figure 1 A pack of cigarettes 1 comprises: a wrapped (i.e. foil wrapped) group of cigarettes 2 (not shown); and a hard outer wrap 3, made of cardboard (cardboard) or the like, for containing the wrapped group 2, and this outer packaging 3 comprises in turn a hard inner packing box 4 and a hard outer packing box 5 that actually accommodate the packaged group 2, and the inner packing box 4 is accommodated in the outer packing box 5 so as to be relative to the outer packing box 5 in closed position ( figure 1 ) and open position ( figure 2 ), wherein, in the closed position, the inner packaging box 4 is fully inserted into the outer packaging box 5, and in the open position, the inner packaging box 4 is partially withdrawn from the outer packaging box 5, which is used to guide the user Contact group 2 with packaging. like image 3 As shown in , the inner packing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com