Method of manufacturing composite bush bearing embedded with solid lubricant

A technology of solid lubricants and manufacturing methods, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems that the runners and risers cannot be commercialized, and it is difficult to produce efficient and cheap manufacturing methods to achieve The effect of ensuring soundness of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Specific embodiments of the present invention will be described based on the drawings.

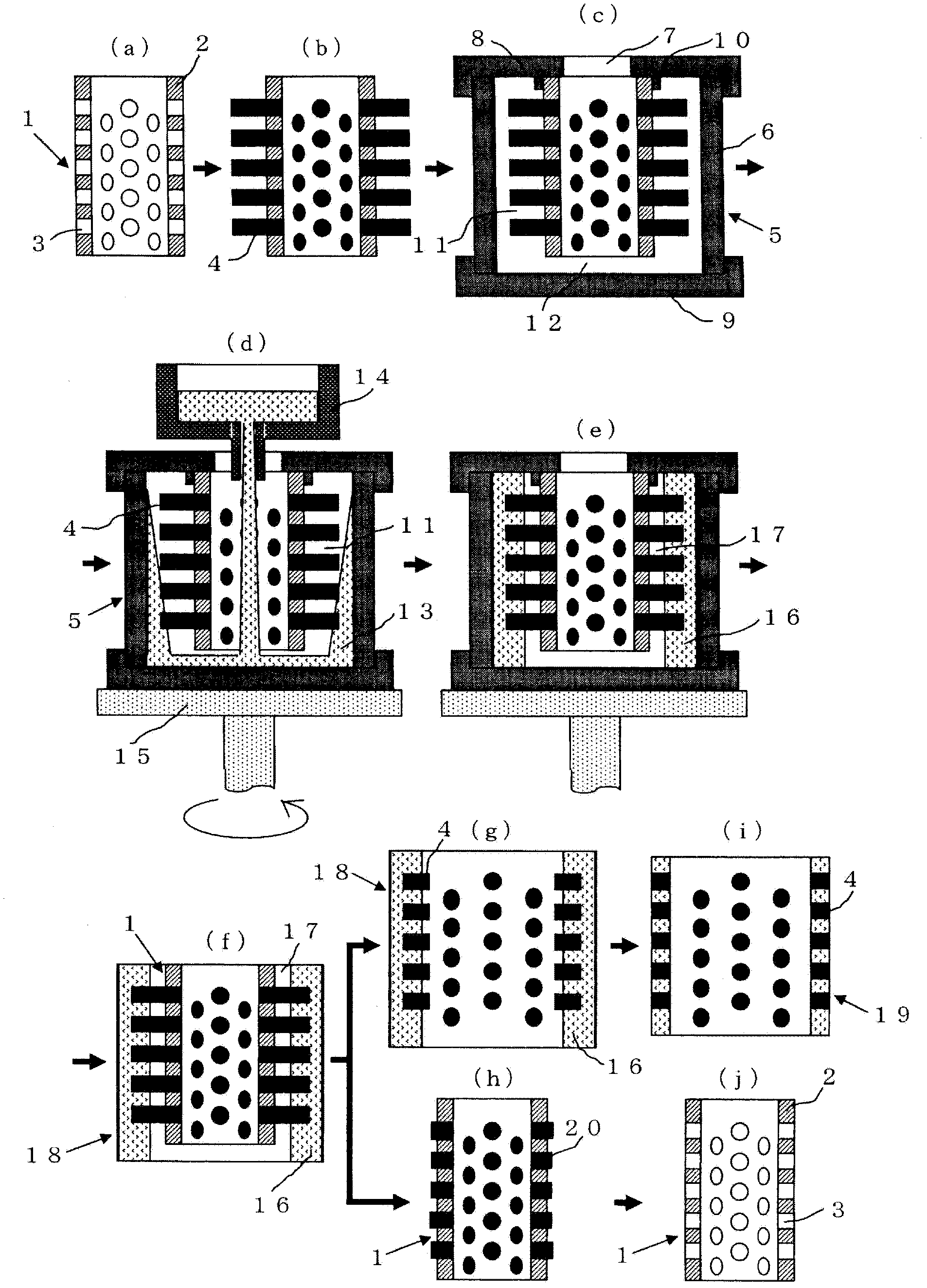

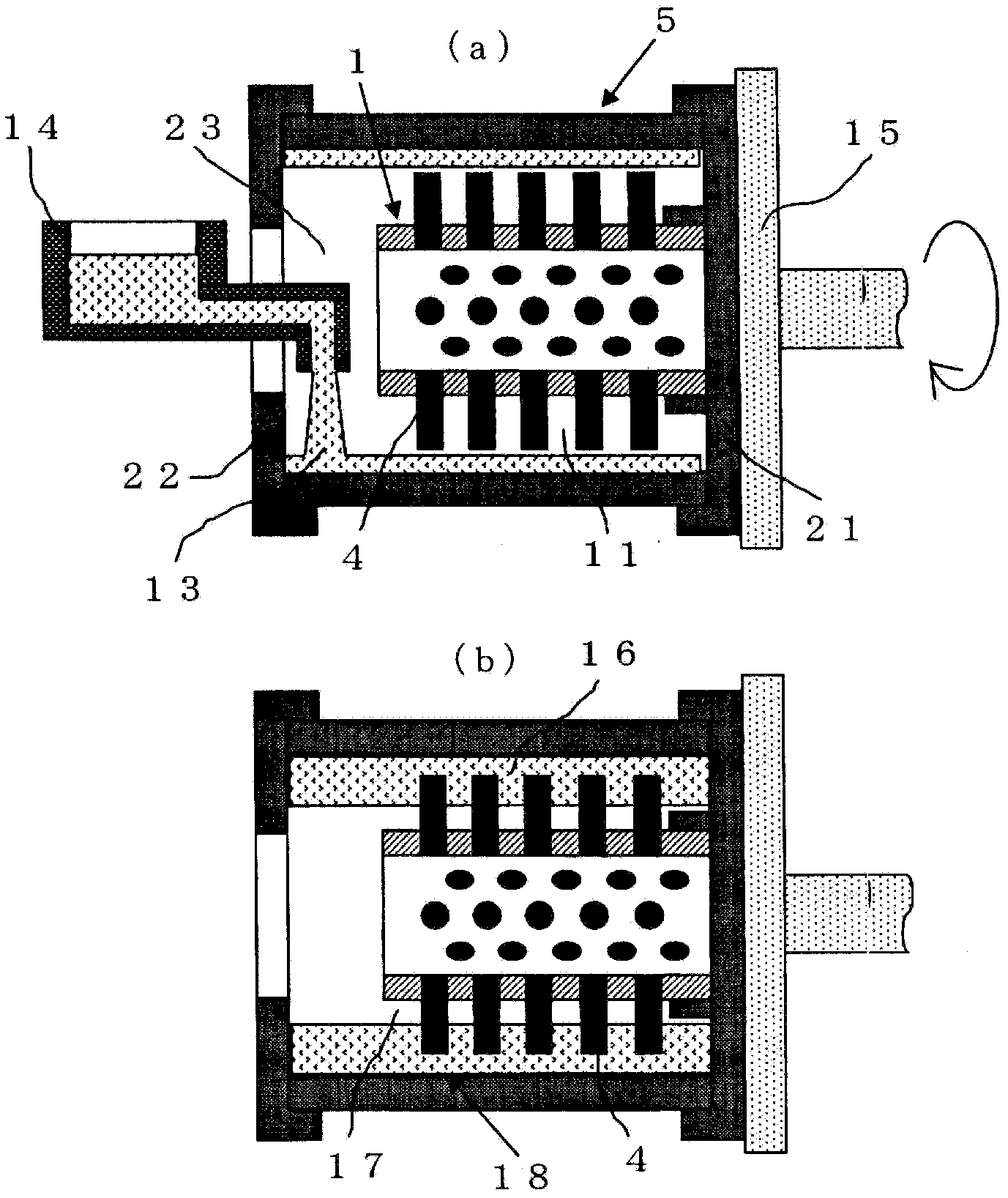

[0031] This embodiment is a manufacturing method based on vertical centrifugal casting, figure 1 (a)~ figure 1 (j) is a process chart showing the manufacturing process in time series.

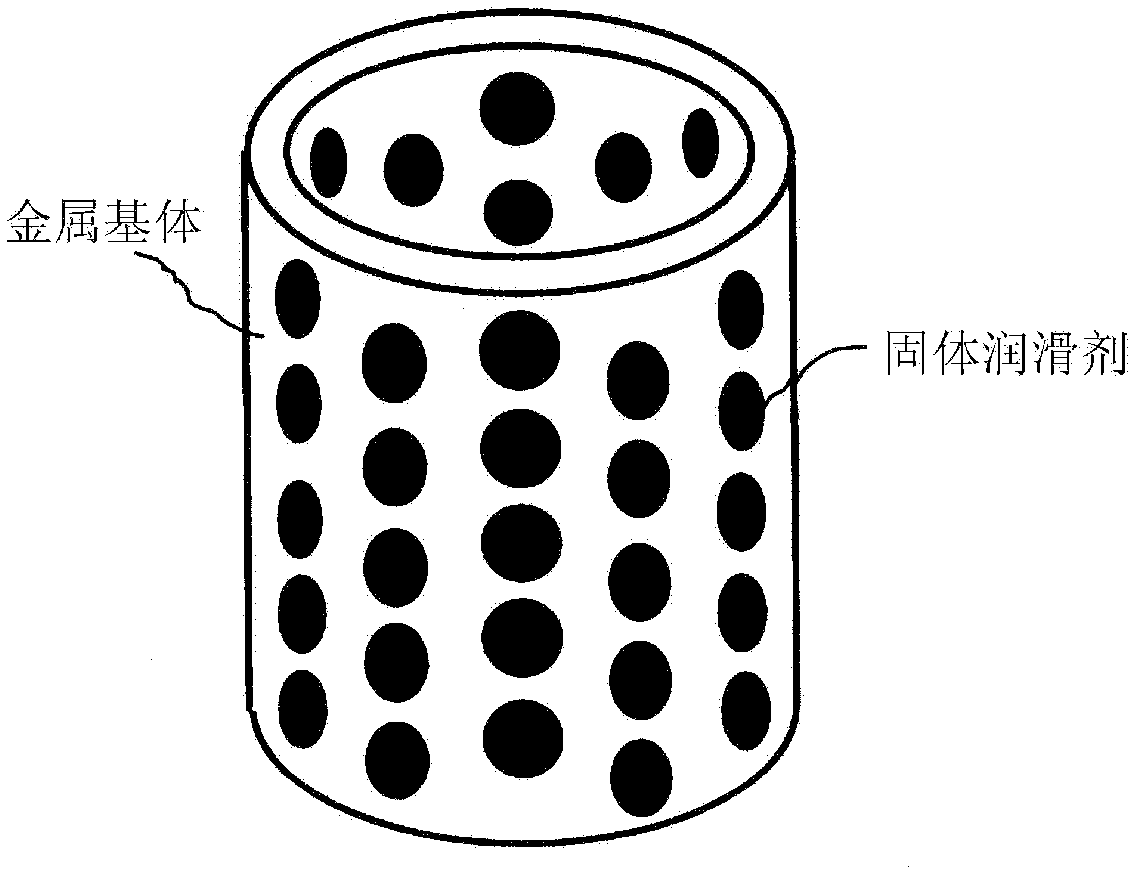

[0032] As the first process diagram figure 1 (a) is a cross-sectional view of the inner cylinder 1 used for assembling the solid lubricant. On its peripheral wall 2, it matches the embedding pattern of the solid lubricant in the solid lubricant-embedded composite sliding bearing product to be manufactured A through hole 3 for embedding and fixing the solid lubricant 4 is opened. As the material of the inner cylinder 1, any material that can withstand repeated use at high temperatures is sufficient. In this embodiment, an S45C round tube machined to a size of 40 mm in outer diameter, 30 mm in inner diameter, and 95 mm in height is used. 40 through-holes 3 with a diameter of 8 mm are opened in the perip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com