Method for manufacturing ashless coal

A manufacturing method and technology for ash-free coal, which are applied in the petroleum industry, solid fuels, fuels, etc., can solve problems such as difficulty in mixing and caking coal, and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

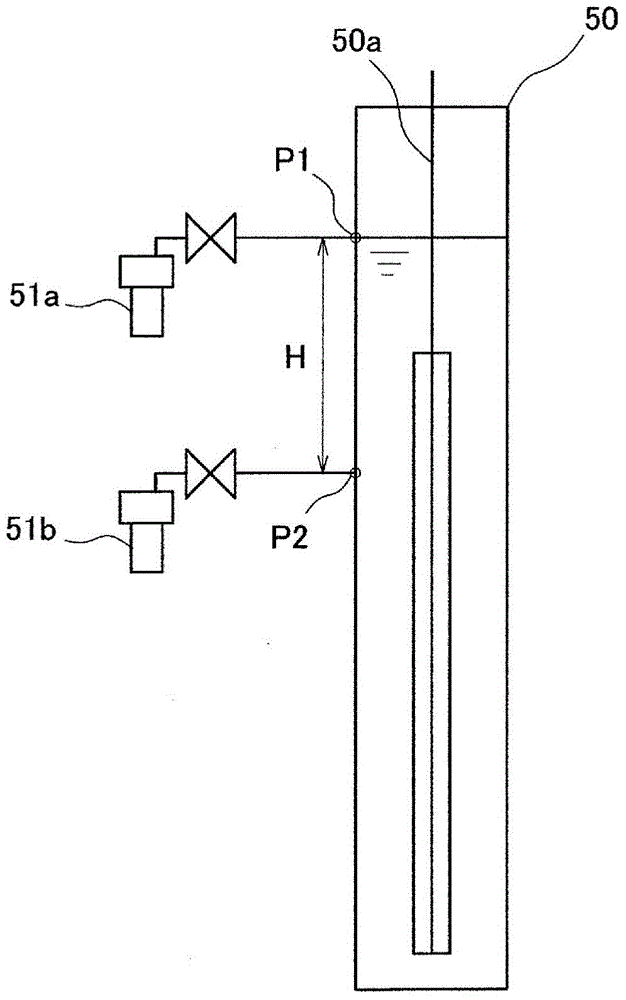

[0021] Such as figure 1 As shown, the ashless coal manufacturing facility 100 is equipped with the following in order from the upstream side of the ashless coal (HPC) manufacturing process: a coal hopper 1, a solvent tank 2, a slurry preparation tank 3, a transfer pump 4, and a preheater 5 , Extraction tank 6, gravity settling tank 7, filter device 8, and solvent separator 9·10.

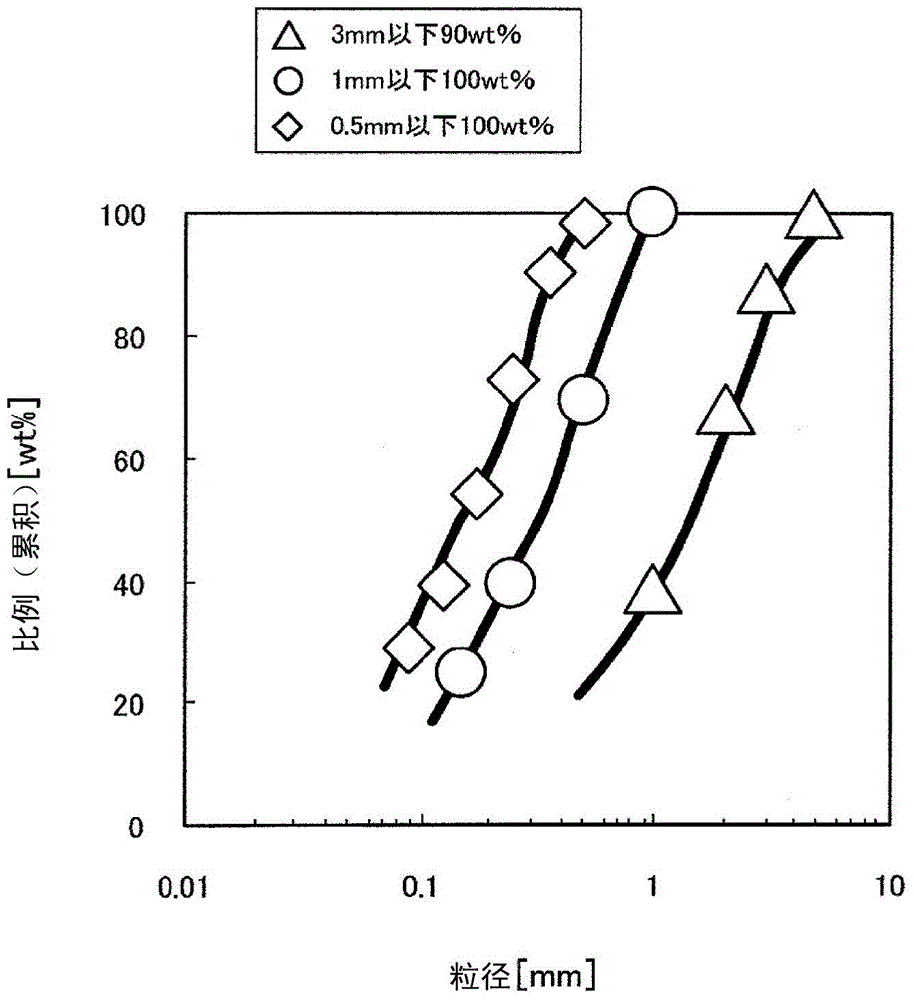

[0022] Here, the method for producing ash-free coal according to this embodiment includes a particle size adjustment step, an extraction step, a separation step, an ash-free coal acquisition step, and a by-product coal acquisition step. Hereinafter, each step will be described. In addition, in this production method, the coal used as a raw material is not particularly limited, and bituminous coal with a high extraction rate (the ratio of the soluble content of the coal extracted by the solvent) can be used, and cheaper low-quality coal (sub-bituminous coal, lignite). In addition, the term "ashless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com