A sludge dewatering device

A sludge dewatering and set-up technology, applied in water/sludge/sewage treatment, sludge treatment, dewatering/drying/concentrated sludge treatment, etc. Ensure that the inorganic flocculant is mixed with the sludge evenly, the dehydration efficiency and the discharge efficiency of the dehydration separator are low, etc., so as to achieve the effect of good dehydration, refining sludge and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

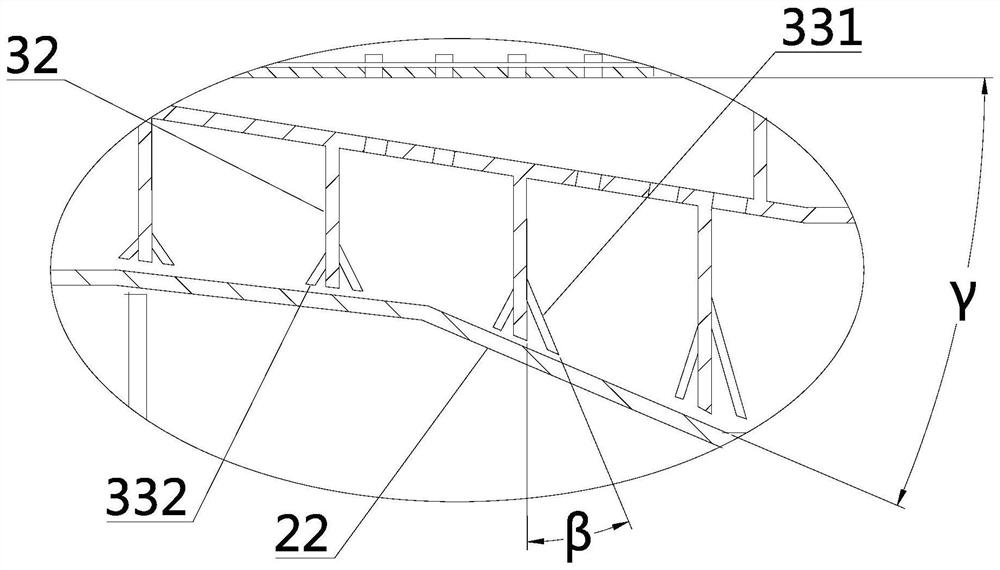

[0014] In the present invention, the guide surface corresponding to the tapered section refers to the guide surface on the blocking plate on the stirring blade correspondingly matched with the tapered section, and similarly, the guide surface corresponding to the straight section refers to the stirring blade correspondingly matched with the straight section The guide surface on the stop piece on the top.

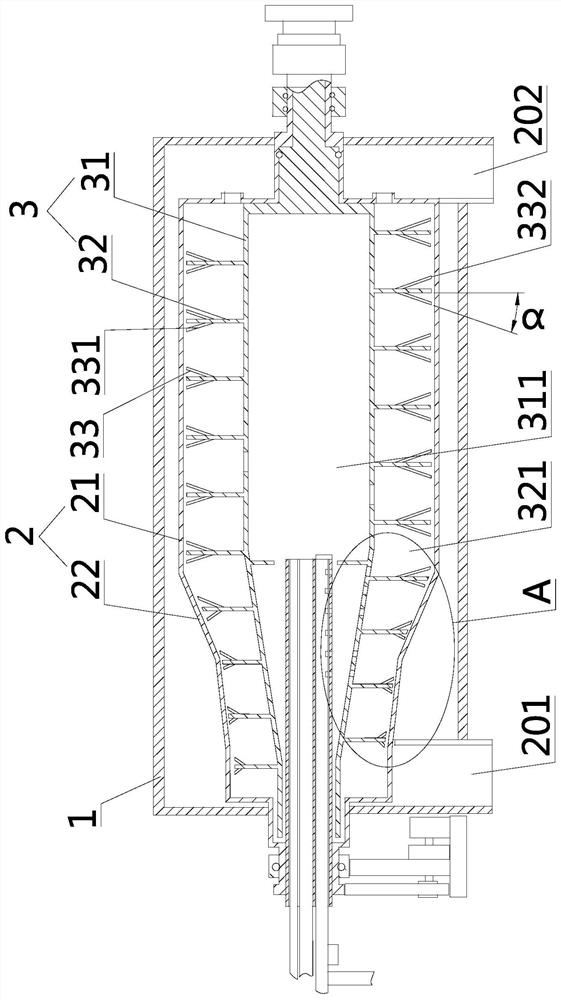

[0015] The invention provides a sludge dewatering device, such as figure 1 and figure 2 As shown, it includes a casing 1, a rotating cylinder 2 set inside the casing 1, and a stirring frame 3 set inside the rotating cylinder 2. The stirring frame 3 includes a main body 31 and stirring blades 32. The inside of the main body 31 is provided with a sludge injection The supply chamber 311, the stirring blade 32 and the rotating cylinder 2 form a separation chamber 321 communicating with the supply chamber 311, and the two ends of the rotating cylinder 2 are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com