Corona protecting method of stator winding cable of straight line motor

A linear motor, stator winding technology, applied in the shape/style/structure of winding insulation, electric components, organic insulators, etc., can solve the problems of loss of insulation performance, insulation aging, accelerated cable outer sheath and insulation layer corrosion, etc. Achieve the effect of suppressing local temperature rise, reducing field distortion rate and reducing corona discharge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

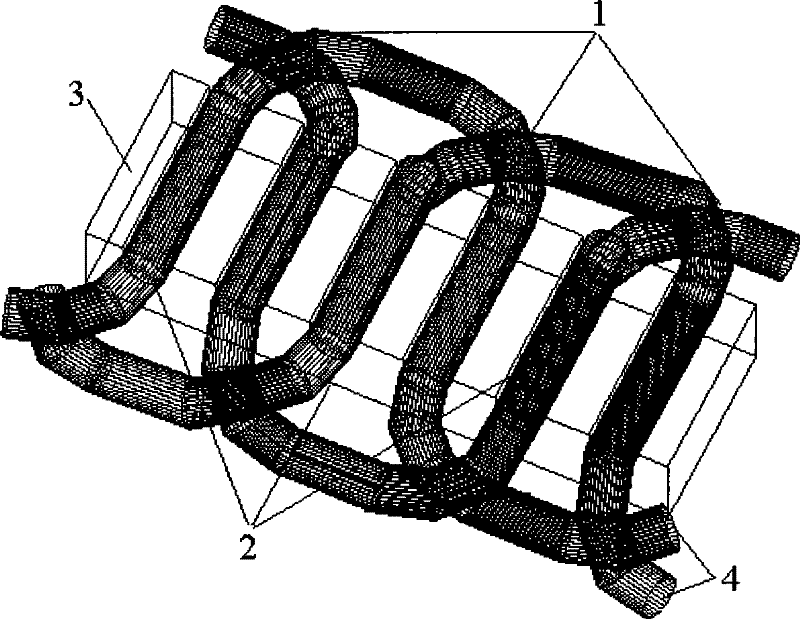

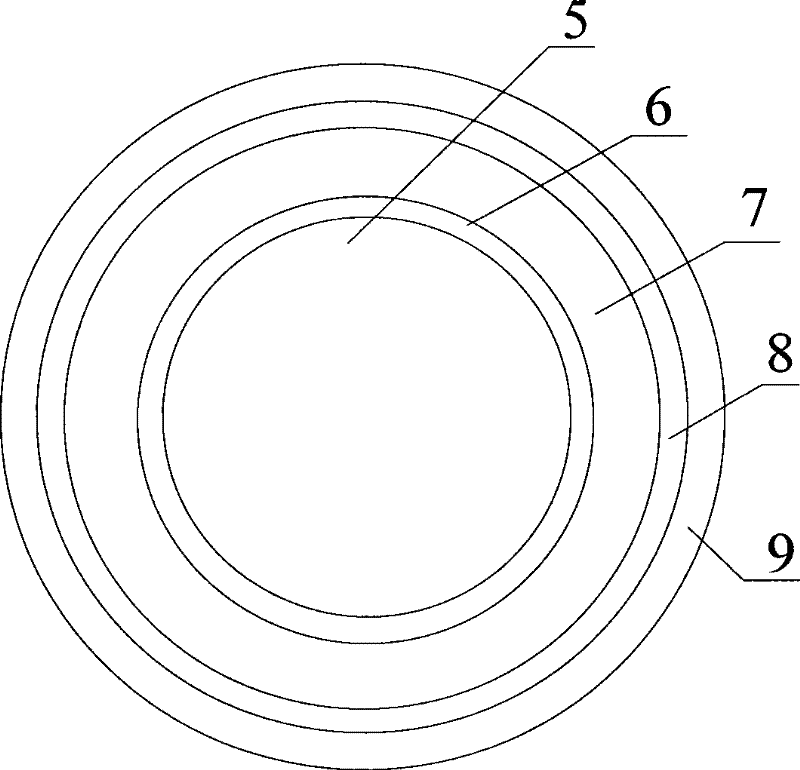

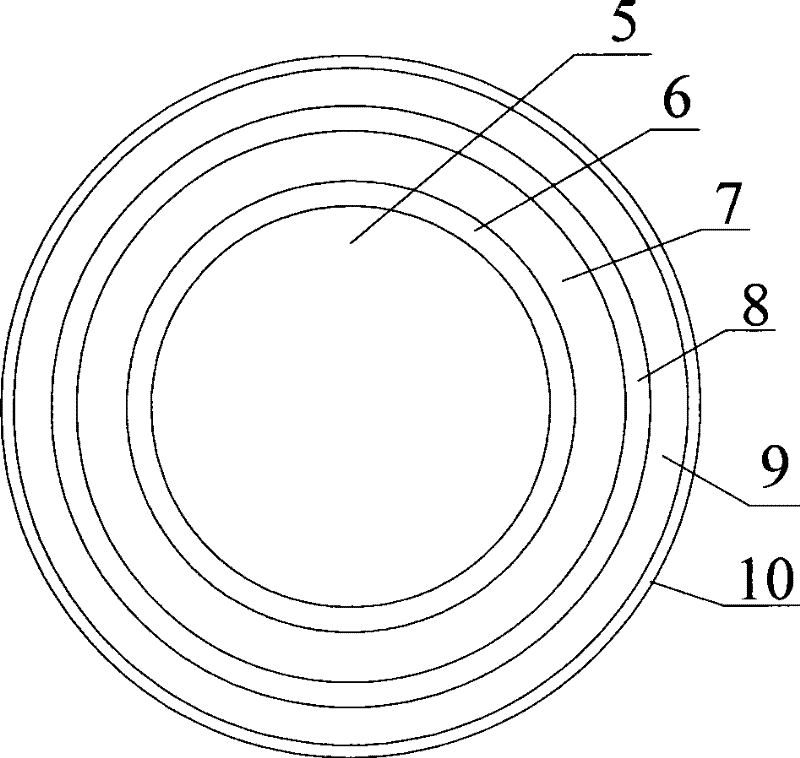

[0011] figure 1 The structural representation of the linear motor stator 3 and the winding cable 4 of the present invention is provided. The specific embodiment of the present invention is to uniformly coat the surface of the cable outer sheath 9 located in the linear motor stator slot and at the slot opening 2 with the first Antihalation paint 10 (see image 3 ), the second anti-halation paint 11 is evenly coated on the surface of the cable outer sheath 9 at the overlapping position 1 of the two-phase cables at the end of the linear motor (see Figure 4 ), wherein the resistivity of the first anti-halation paint 10 is lower than the resistivity of the winding cable outer sheath 9, and the resistivity of the second anti-halation paint 11 is higher than the resistivity of the winding cable outer sheath 9.

[0012] The resistivity value of the first anti-halation paint 10 is about between 2~20Ω·cm, which can be obtained by adding nano-scale Al to the main insulating material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com