Annealing and cooling device for conductive wire

A technology of cooling device and wire guide device, which is applied in the manufacture of cables/conductors, the manufacture of extensible conductors/cables, heat treatment equipment, etc. The effect of wire and cable quality, avoiding surface oxidation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

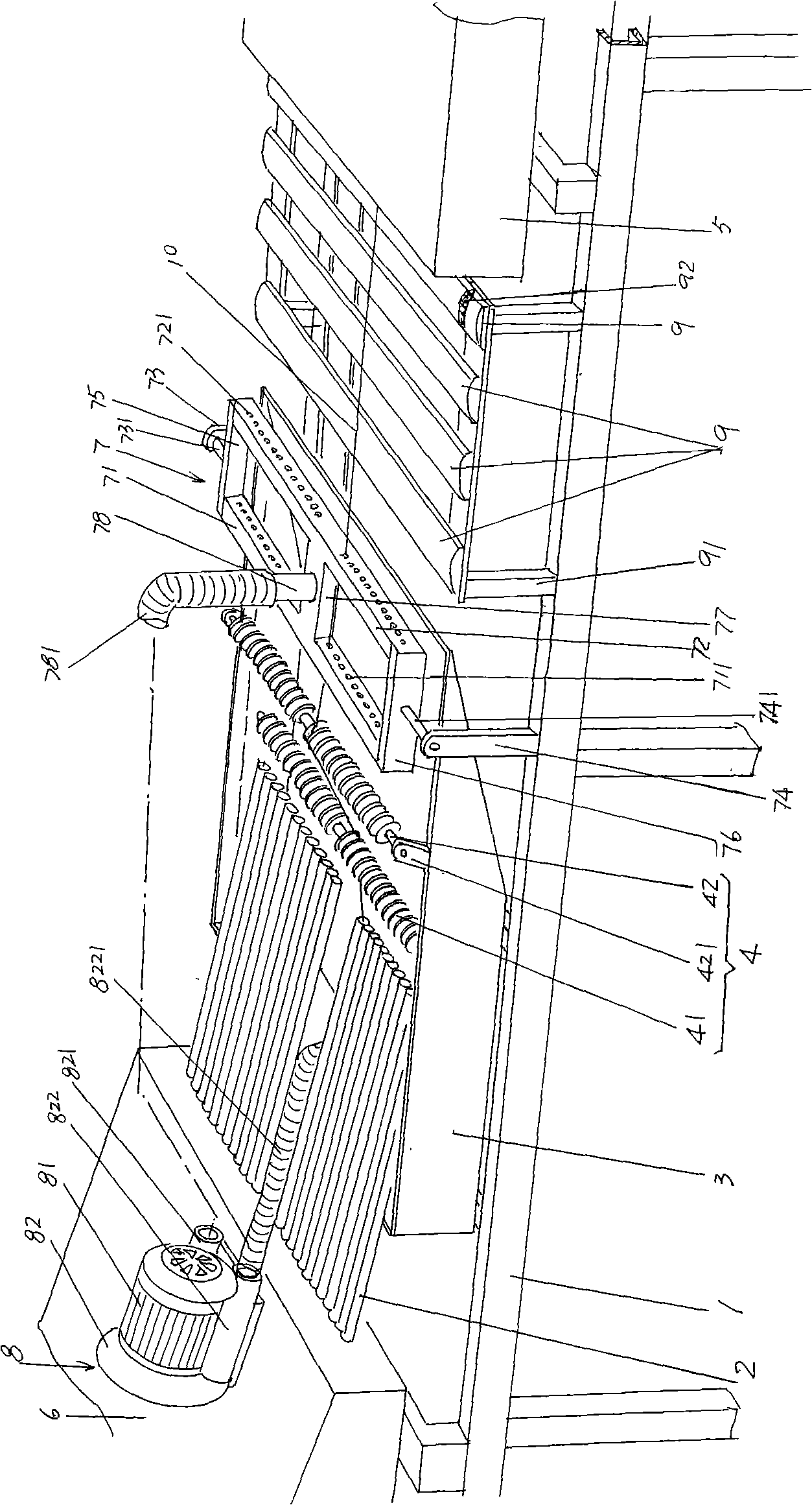

[0014] In order to enable your examiners, especially the public, to further understand the structural features and beneficial effects of the present invention, the specific implementation of the present invention is described in detail below in conjunction with the examples, but the description of the examples does not constitute a limitation on the technical solution of the present invention. Formal but not substantive changes should be regarded as the scope of the technical solutions disclosed in the present invention.

[0015] Please refer to the accompanying drawings, take the current illustrated position as an example, the left end of the frame 1 is an annealing furnace 6, the wire 10 obtained by the previous process such as a wire drawing process enters the annealing furnace, and after the annealing is completed, it is connected to the annealing furnace A group of guide wire tubes 2 (also can be called lead wire tubes) at the lead wire outlet of 6 are drawn out. The guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com