Intelligent container sling based on omniberaing vision sensor

An omnidirectional vision, container spreader technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of low hoisting efficiency, time-consuming and laborious hoisting process, and high requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

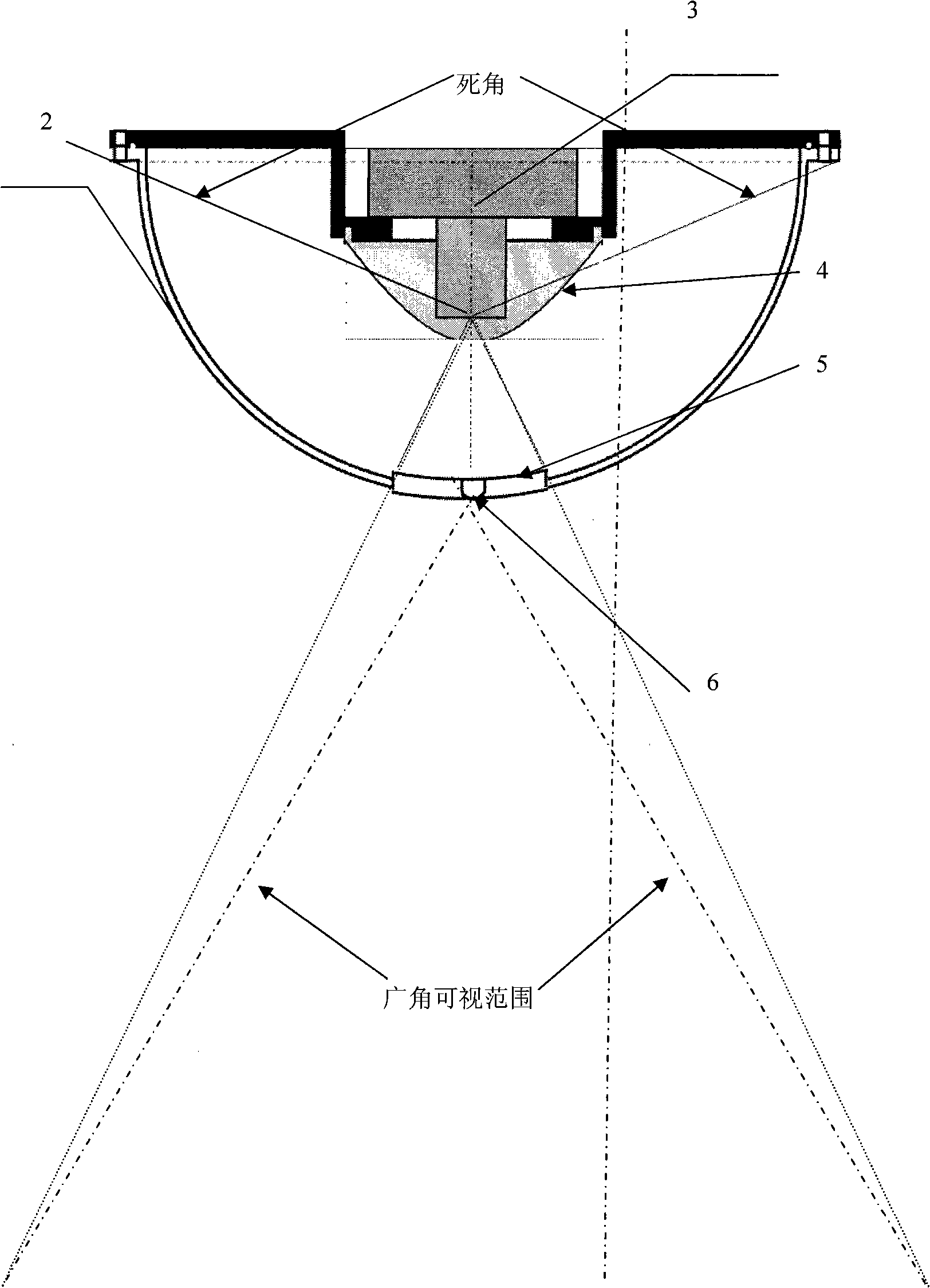

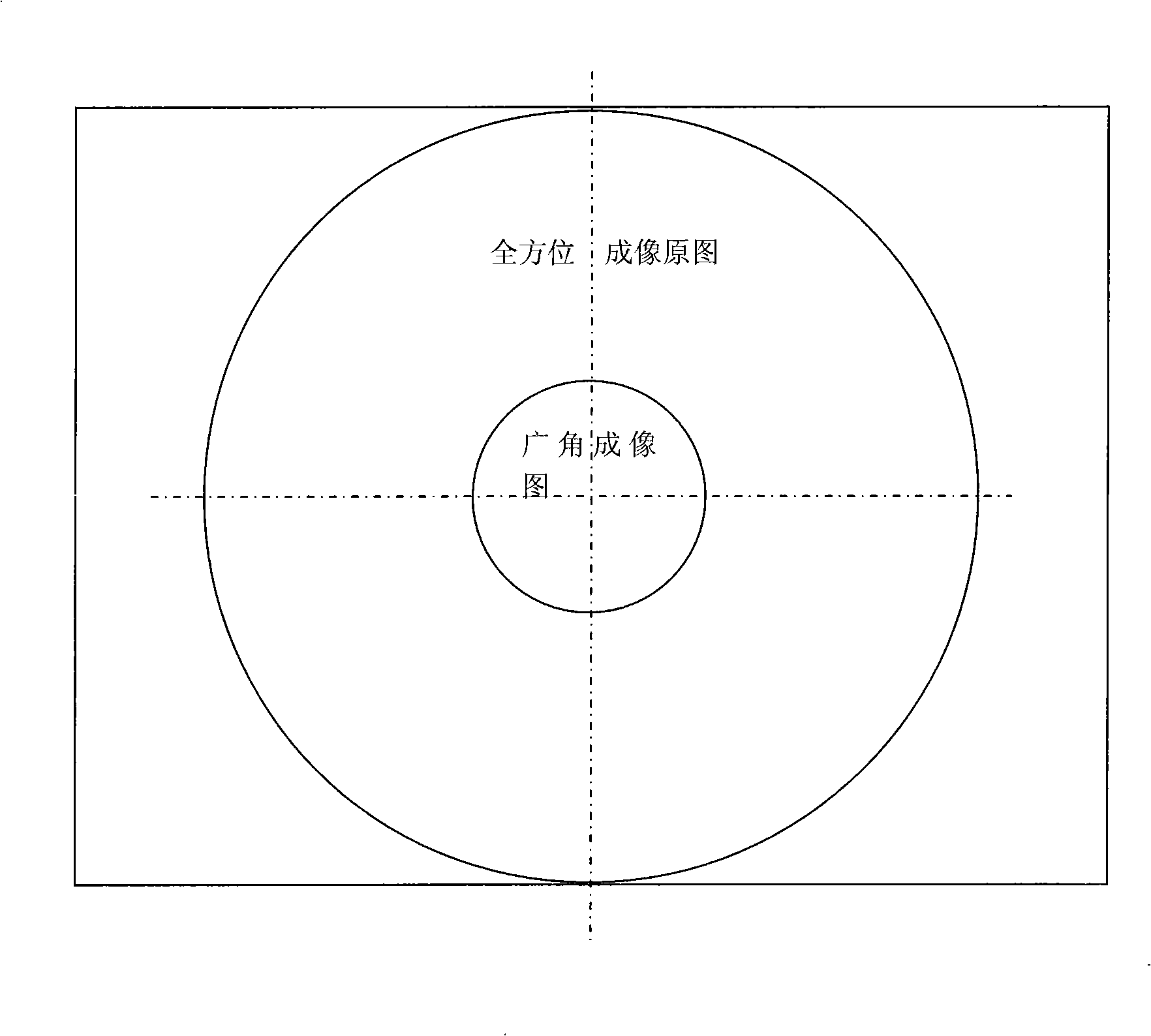

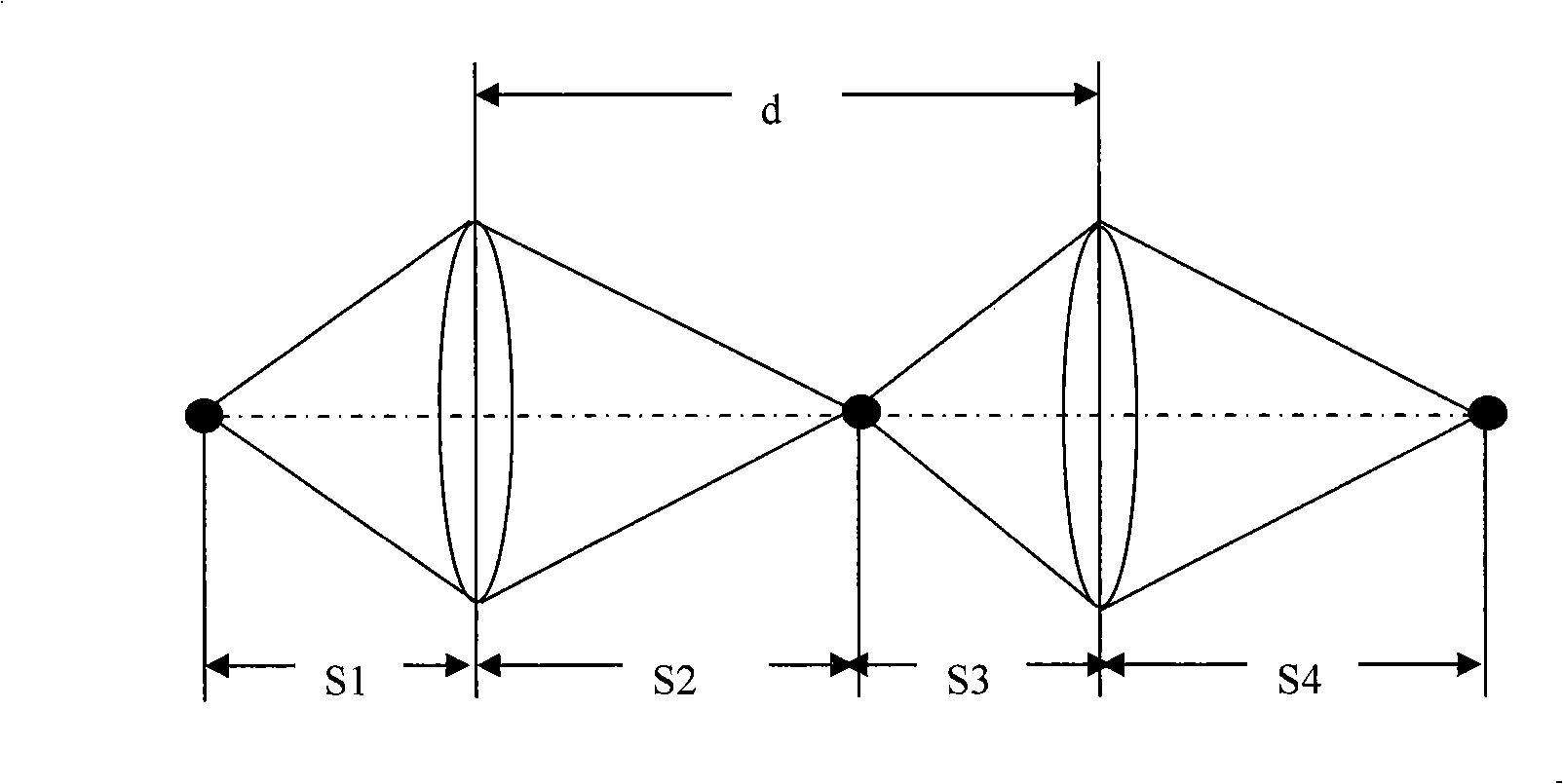

[0088] refer to Figure 1 to Figure 14 , the present embodiment installs omni-directional vision sensor 9 on the middle and lower part of spreader 8, such as Figure 7As shown, the installation requirement is that the omnidirectional vision sensor can capture the video image of the entire container and its surroundings, and the center of the obtained video image is required to coincide with the center of the spreader; The microprocessor is connected with the microprocessor, and the microprocessor reads the video image obtained by the omnidirectional vision sensor, detects and calculates the deviation degree between the twist lock of the spreader 8 and the keyhole of the container 7 through software, and outputs related control according to the deviation state The electro-hydraulic proportional valve is controlled by D / A conversion to realize the translational movement of the boom and the extension and rotation of the spreader, and finally automatically and accurately insert th...

Embodiment 2

[0162] refer to Figure 1-Figure 14 , the omni-directional vision sensor of this embodiment adopts the mode of wireless communication with the PC, transmits the video image around the top of the container to the computer through wireless mode, and the computer calculates the twist lock and the twist lock on the spreader according to the given algorithm. The deviation between the lock holes of the container, and then according to the deviation state, the computer outputs the relevant control amount through the electro-hydraulic proportional control technology to realize the telescopic and pitching of the boom and the telescopic and rotating actions of the spreader to realize the twist lock on the spreader Accurately insert into the keyhole of the container.

[0163] All the other structures and working process are identical with embodiment 1.

Embodiment 3

[0165] refer to Figure 1-Figure 14 In this embodiment, the driver uses the video image obtained by the omnidirectional visual sensor displayed on the screen in the cab, and the driver quickly inserts the twist lock on the spreader into the lock hole position of the container accurately according to the prompt on the screen .

[0166] All the other structures and working process are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com