Discharge gas ejection dust emission device and its silencer

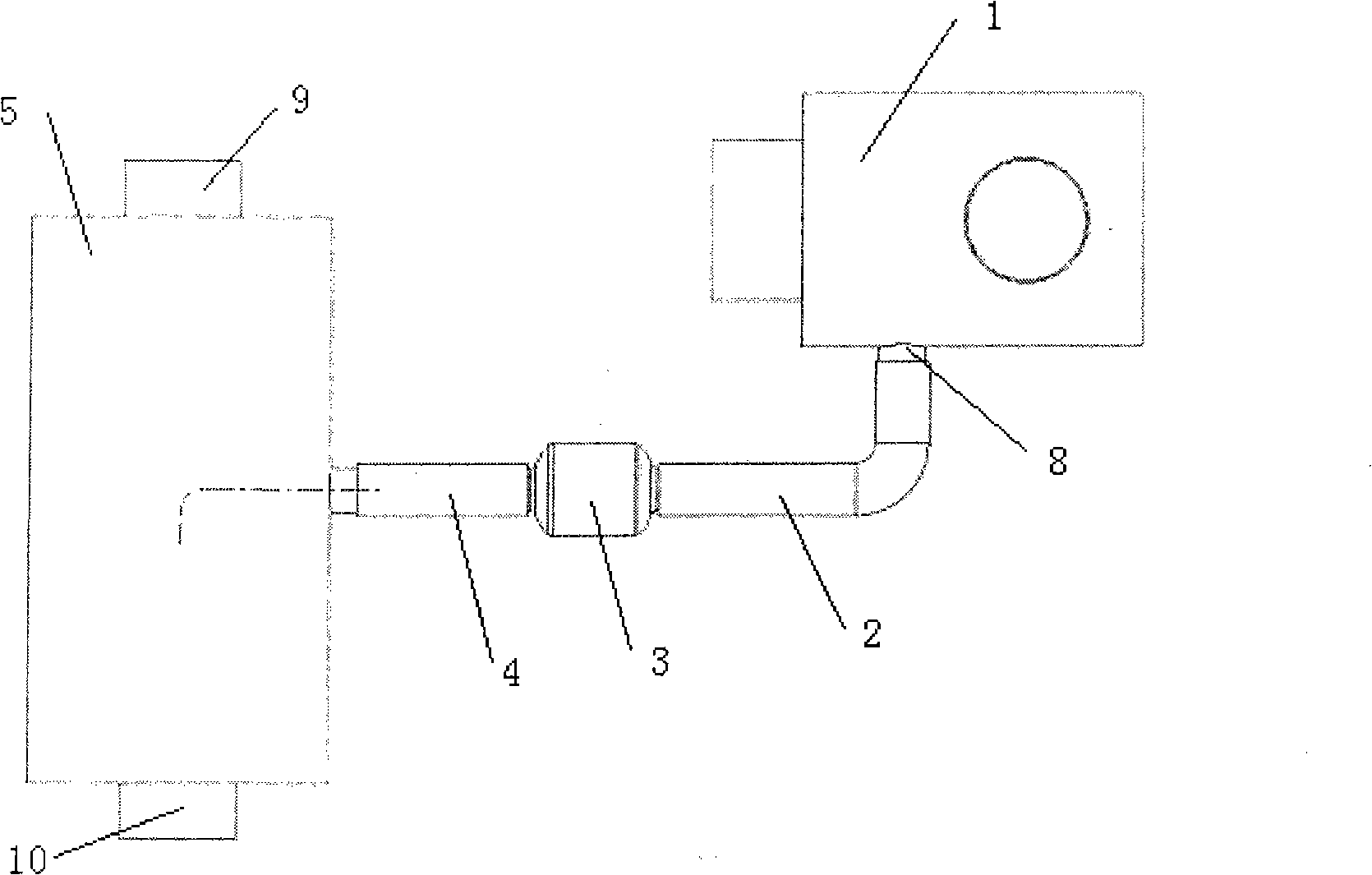

A muffler and exhaust gas technology, which is applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc., can solve the problems of short exhaust tailpipes and small layout space, and achieve small vehicle space occupation, easy layout and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

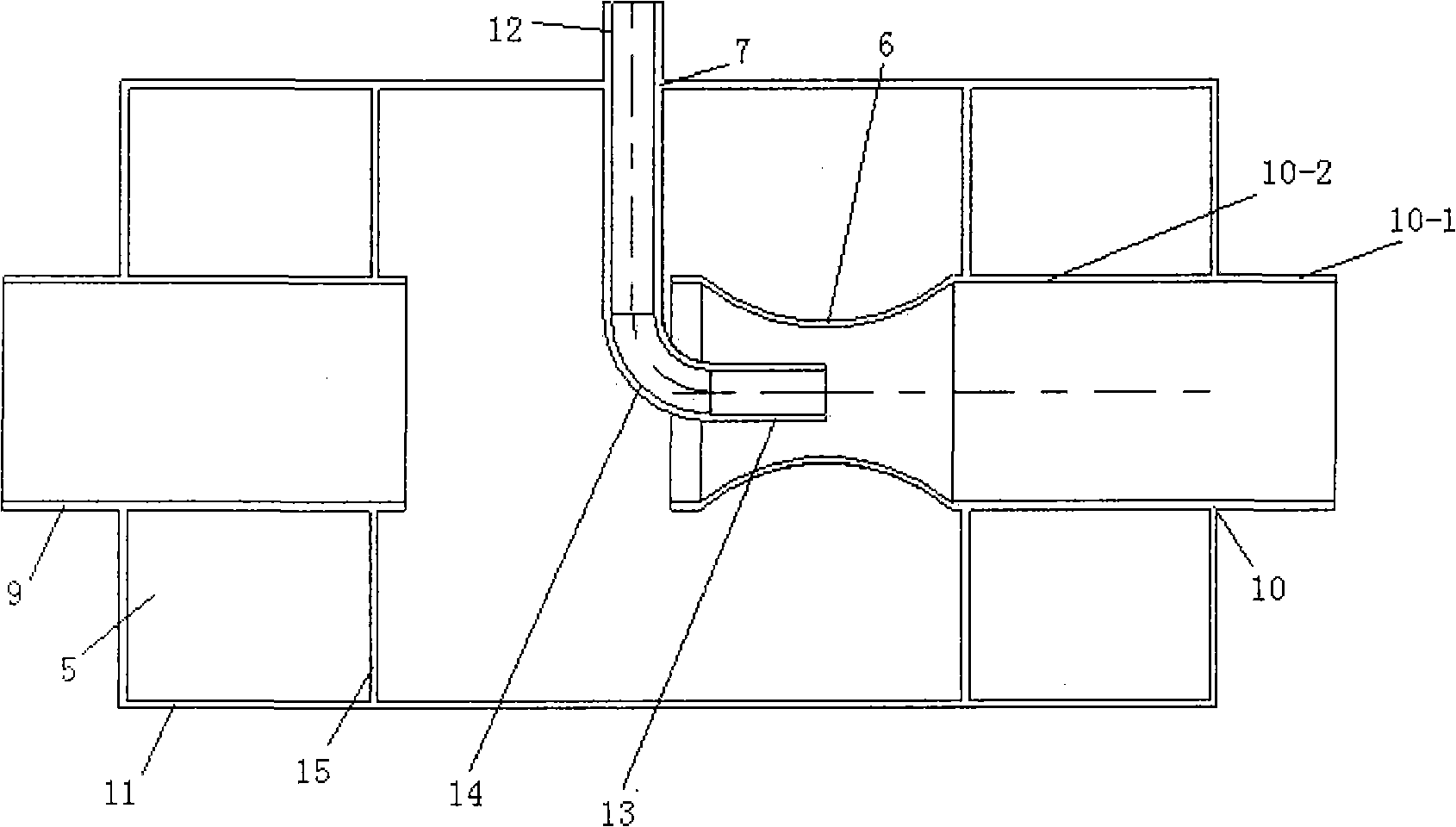

[0019] Such as figure 2 As shown, the muffler 5 is a columnar cavity, one end of which is provided with an exhaust inlet pipe 9, and the other end is provided with an air outlet pipe 10; the housing of the muffler 5 is provided with a muffler structure 15, and the muffler structure 15 is an existing structure and is not limited in the illustrated structure. The shell 11 of the muffler 5 is provided with an ejector pipe 7, the inlet section 12 of the ejector pipe 7 is arranged outside the muffler shell, and the ejector pipe 7 extends into the muffler shell. The casing of the muffler and the injection pipe can be connected as one part, or two parts, that is, the injection pipe passes through the casing of the muffler. In this embodiment, the injection pipe and the casing of the muffler are an integral part. The injection pipe 7 is composed of an inlet section 12 , an outlet section 13 and a connecting section 14 that smoothly connects the inlet section 12 and the outlet secti...

Embodiment 2

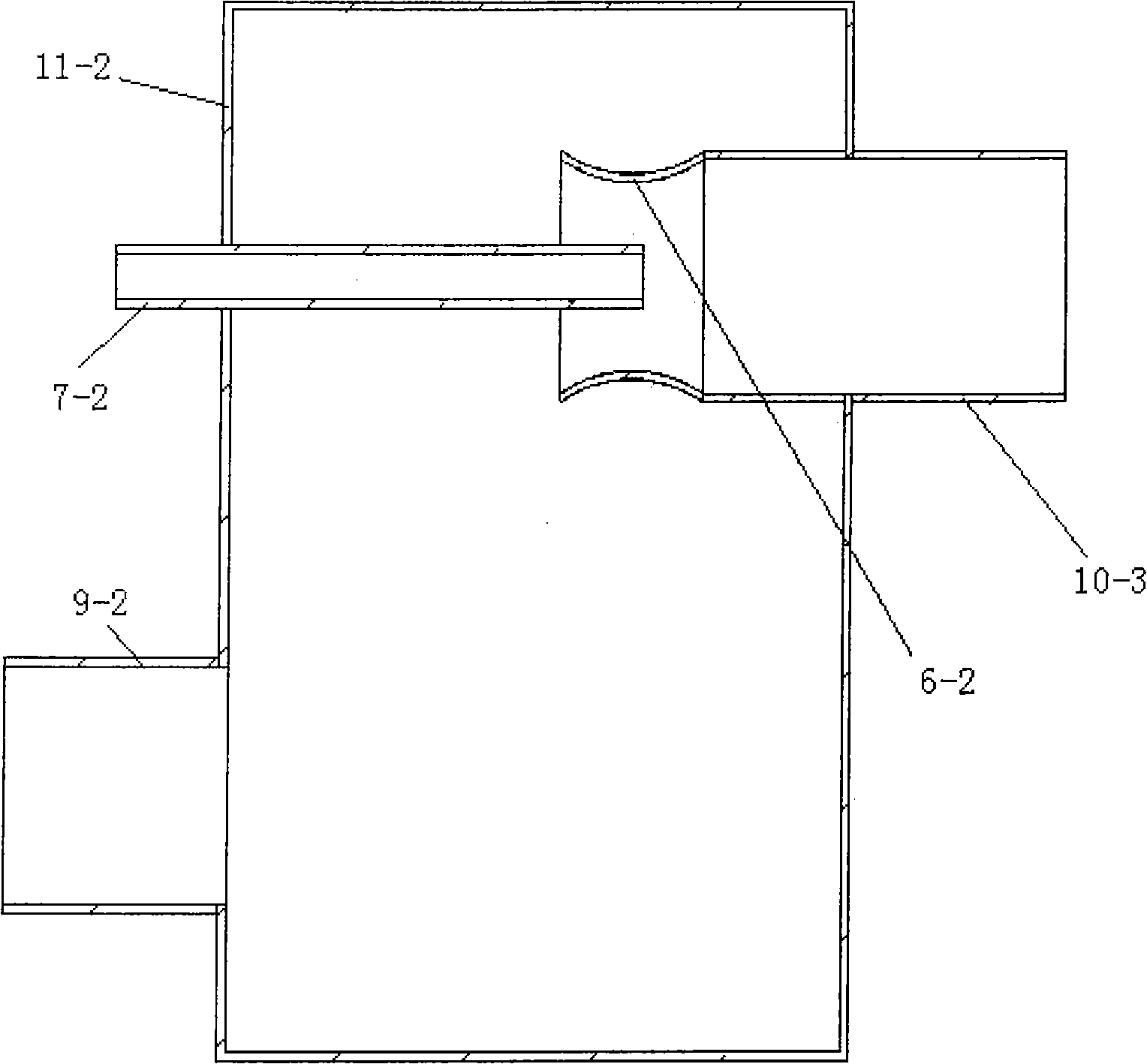

[0022] The communication between the ejector pipe and the throat pipe can also be a straight-through type, such as image 3 As shown, the ejector pipe 7-2 is arranged in parallel with the exhaust inlet pipe 9-2 and the outlet pipe 10-3 of the muffler 5-2, and the throat pipe 6-2 is arranged in the muffler 5-2 and connected with the outlet pipe 10-3 . The straight-through connection reduces the accumulation of dust in the wall of the ejector tube. Of course, the exhaust gas inlet pipe 9-2 and the gas outlet pipe 10-3 may not be in a parallel structure.

Embodiment 3

[0024] Such as Figure 4 As shown, the injection pipe 7-3 is located inside the muffler housing, and the muffler housing has a pipeline installation hole 5-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com