Polycarbonate resin combination

A technology of polycarbonate resin and resin composition, which is applied in the direction of optical recording media, etc., and can solve the problems of difficult optical disc substrate materials, high crystallinity, opacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

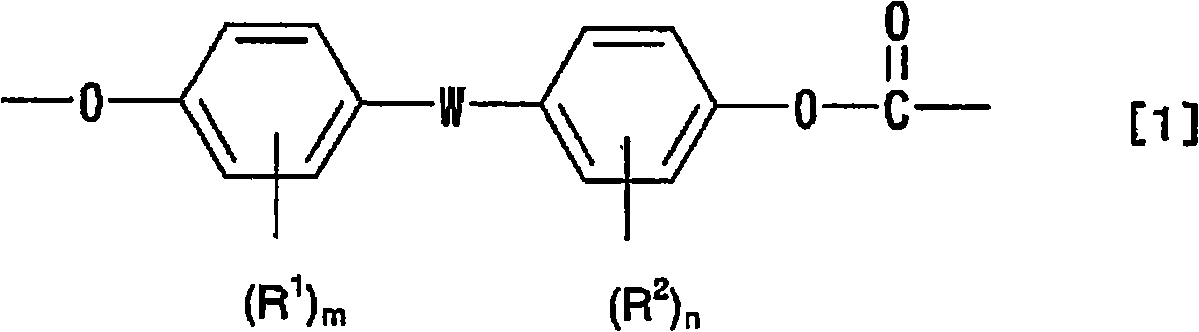

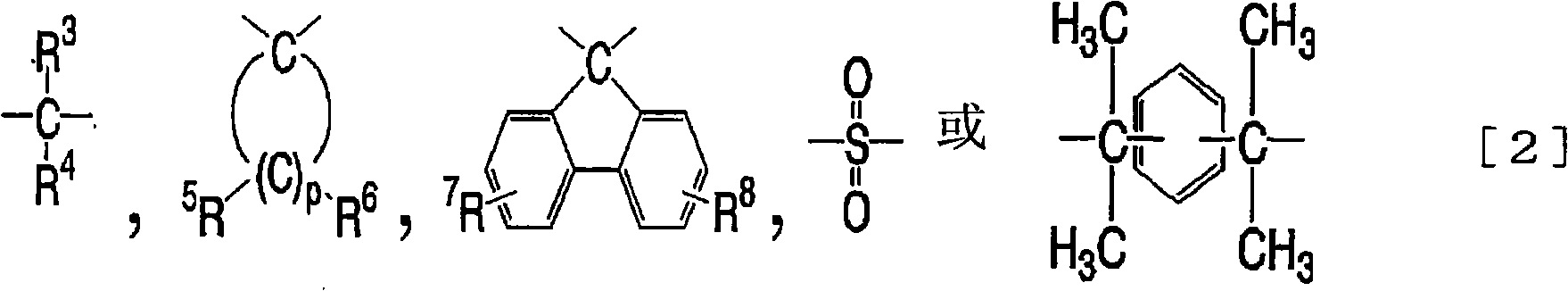

Method used

Image

Examples

Embodiment 1

[0125] 10.0 g of polybutylene succinate ( ピオノレレ 1020, manufactured by Showa Polymer Co., Ltd.), was dry-blended and mixed uniformly. Next, the composition was melt-kneaded while degassing at a cylinder temperature of 280° C. using a vented twin-screw extruder (KTX-46, manufactured by Kobe Steel Co., Ltd.), to obtain resin composition pellets. Shaped tablets are produced from the granules. The glass transition temperature, deformation temperature under load, and water absorption are listed in Table 1.

[0126] Next, after drying the pellets at 120° C. for 5 hours, using an injection molding machine (M-35B-D-DM, manufactured by Meiji Seisakusho Co., Ltd.), at the cylinder temperature and mold temperature listed in Table 1, An optical disc substrate with a diameter of 120 mmФ and a thickness of 0.6 mm and an optical disc substrate with a diameter of 120 mmФ and a thickness of 1.2 mm are injection molded. The obtained optical disc substrates were cut out into dimensions of 50 mm...

Embodiment 2

[0130] 30.0 g of polybutylene succinate ( A molded sheet was produced from the resin composition pellets in the same manner as in Example 1, except for Pionore 1020 (manufactured by Showa Polymer Co., Ltd.). And determine its glass transition temperature, load deformation temperature, water absorption. Furthermore, a substrate was produced by the same method as in Example 1, and light transmittance was measured. In addition, by the same method as in Example 1, a DVD-ROM disc was obtained.

[0131] Using this optical disc, measurement of radial warpage, evaluation of signal characteristics, and reproduction by a player were carried out. In addition, it was left for 96 hours in an environment with a temperature of 70°C and a humidity of 50%RH specified in the JIS standard (JIS X 6241; 1997 and JIS X 6245; 1999), and then at a temperature of 23°C and a humidity of 50%RH After leaving it in a normal temperature and humidity environment for 24 hours, measurement of radial warpag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com