Relay

A relay and electromagnet technology, applied in the field of high-frequency relays, can solve the problems of low productivity, small degree of freedom, and difficulty in processing the movable iron piece 5, and achieve the effects of high productivity, low friction, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

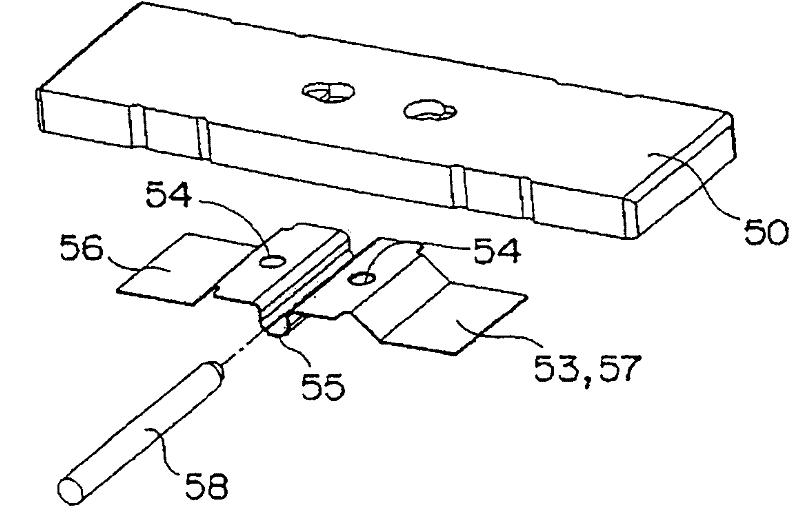

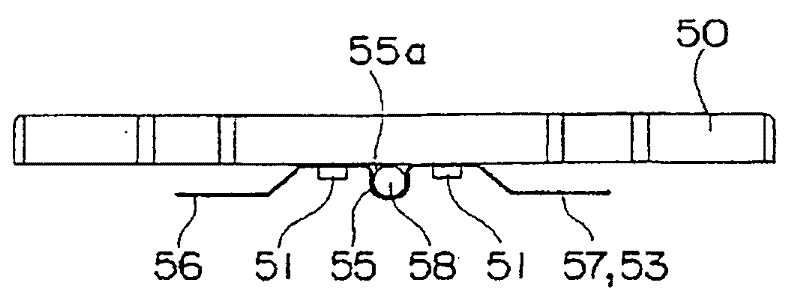

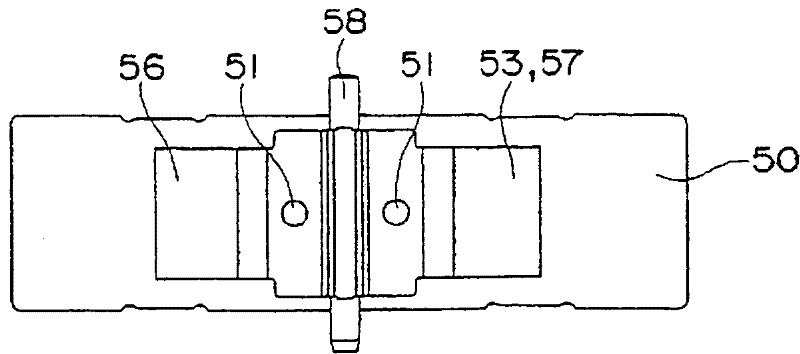

[0086] based on Figure 1 ~ Figure 2 3. A coaxial relay to which an embodiment of the present invention is applied will be described.

[0087] The coaxial relay of this embodiment is roughly constituted by a contact unit 10 , a movable iron piece 50 , an electromagnet unit 60 , a control unit 80 , and a cover 90 .

[0088] The contact unit 10 is composed of a base block 11 , a copper sheet 24 and a contact block 30 . Such as Figure 6 As shown, the base block 11 is a cuboid, and an escape groove 12 is formed in the center of the upper surface. In addition, around the escape groove 12 of the base block 11, a pair of positioning pins 16a, 16b protrude point-symmetrically, and threaded holes 17a, 17b are formed point-symmetrically. In order to ensure the directionality of assembly of the contact block 30, the positioning pins 16a, 16b and the threaded holes 17a, 17b are not arranged in line-symmetrical positions. In addition, through-holes 13 , 14 , and 15 for coaxial connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com