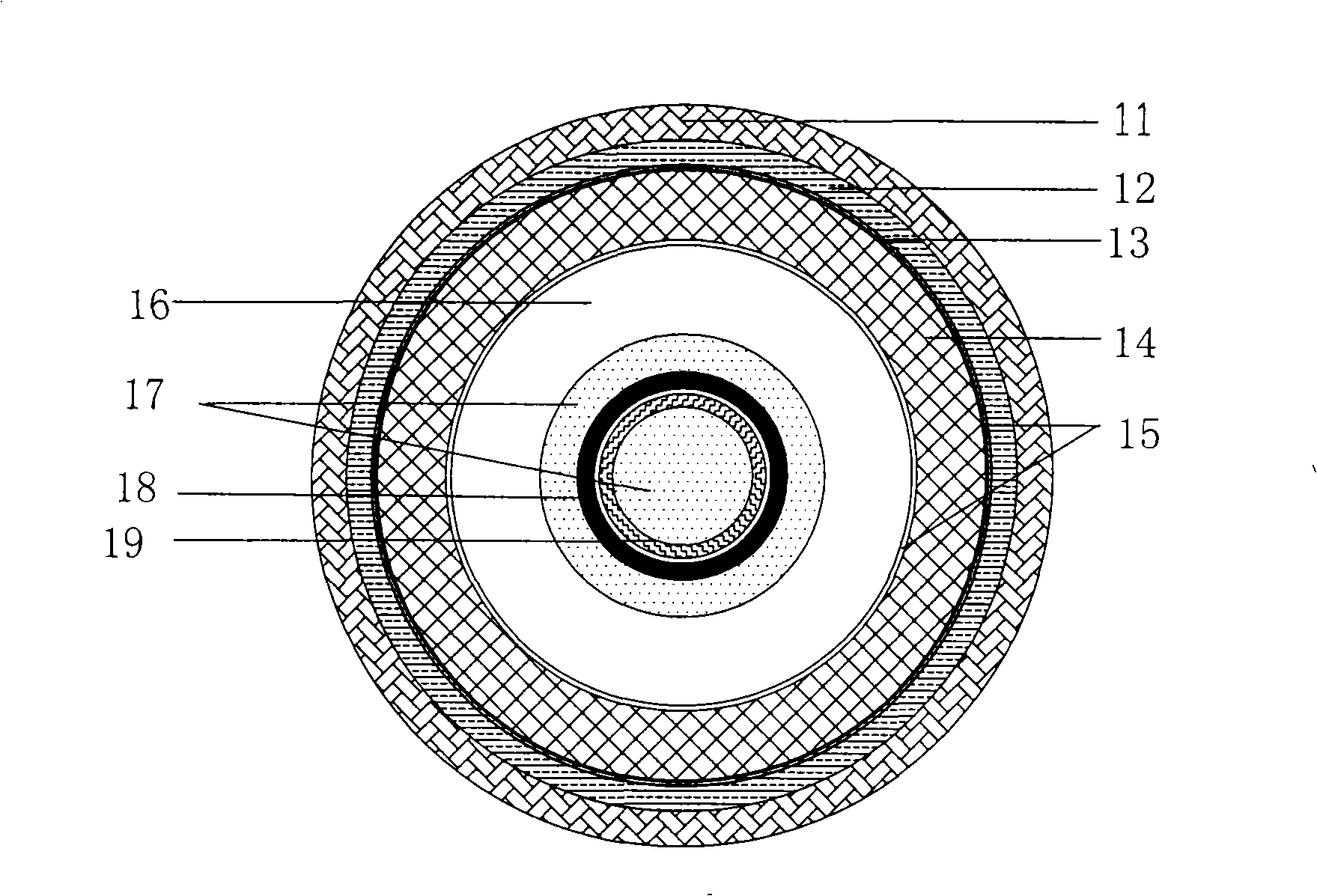

Superconducting cable for insulation and thermal insulation

A superconducting cable, integrated technology, applied in the field of power engineering applications, can solve the problems of no larger cable space, insufficient capacity of conventional cables, etc., to achieve the effects of flexible and convenient connection, enhanced damage resistance, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A superconducting cable (80 meters long) for powering a DC 200kA class aluminum electrolytic cell

[0039] The outer shell and inner tube are made of stainless steel plates. Due to the low voltage, the interlayer insulators are disc-type and made of temperature-resistant polytetrafluoroethylene, and are arranged every 5 meters. A set of corrugated telescopic section structures with a length of 500mm is arranged at a distance of 25 meters from both ends. The interlayer between the outer shell and the inner tube draws a lower vacuum for insulation.

Embodiment 2

[0040] Embodiment 2: Cable busbar (150 meters long) for the outlet of AC 26kA generator

[0041] The shell and the inner tube are made of rolled aluminum plates, and the interlayer insulators are made of polytetrafluoroethylene rods resistant to temperature changes. A set of insulators is arranged every 8 meters, and the number of insulators on the cross-section perpendicular to the cable at each support point is 4 indivual. A set of corrugated telescopic section structures with a length of 600mm are arranged every 30 meters on the shell and the inner pipe respectively. The interlayer between the outer shell and the inner tube is filled with lightweight airgel powder insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com